Calibration system and method of on-line monitoring device for dissolved gas in transformer oil

A monitoring device, transformer oil technology, applied in the direction of material inspection products, etc., can solve the problems of poor monitoring result accuracy, reduced dielectric strength, interference equipment fault monitoring and diagnosis, etc., to ensure accuracy, ensure safety, and avoid false alarms and underreporting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

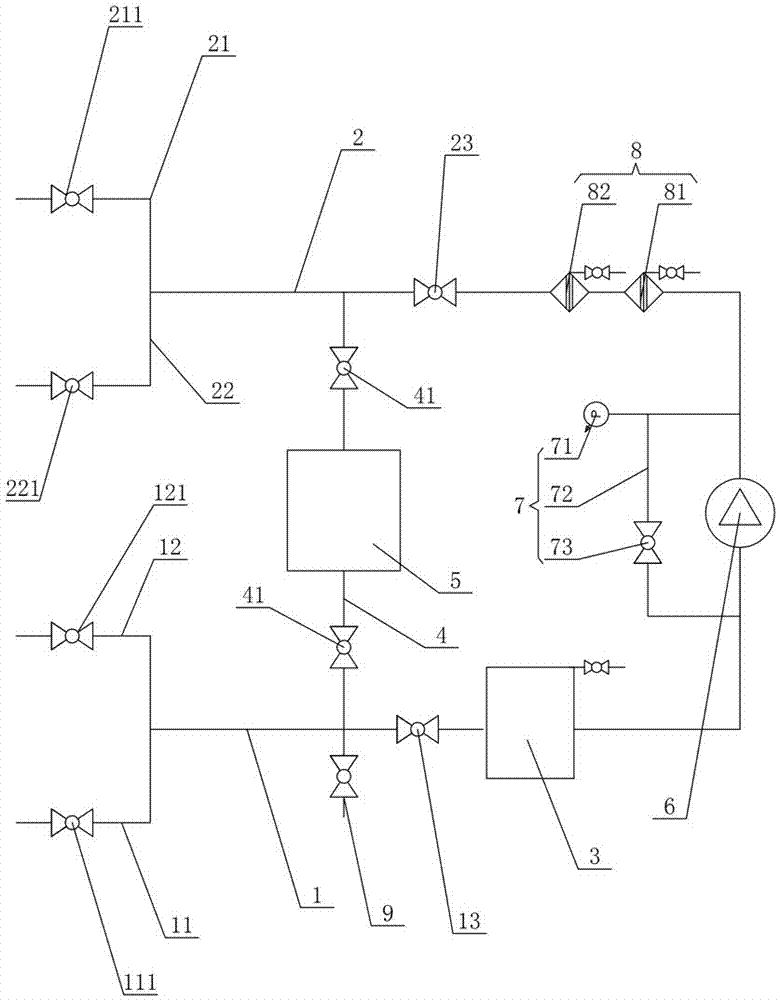

[0030] Such as figure 1As shown, an embodiment of the verification system of the online monitoring device for dissolved gas in transformer oil of the present invention includes an oil inlet main pipe 1 and an oil outlet main pipe 2 connected to each other. The transformer oil inlet pipe 11 connected to the oil outlet of the online monitoring device and the monitoring device oil inlet pipe 12, the transformer oil inlet pipe 11 and the monitoring device oil inlet pipe 12 are respectively equipped with a transformer oil inlet pipe control valve 111 and a monitoring device oil inlet pipe Control valve 121, the outlet end of oil outlet main pipe 2 is provided with transformer oil outlet branch pipe 21 and monitoring device oil outlet branch pipe 22 respectively connected with transformer and online monitoring device oil inlet end, transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com