Bent type, stepped type and corrugated type noise reduction devices for cooling tower

A cooling tower and noise reduction technology, applied in water shower coolers, heat exchanger types, instruments, etc., can solve the problems of increased ventilation resistance, increased water temperature out of the tower, decreased cooling capacity, etc., to achieve increased ventilation area, The effect of reducing ventilation resistance and improving cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

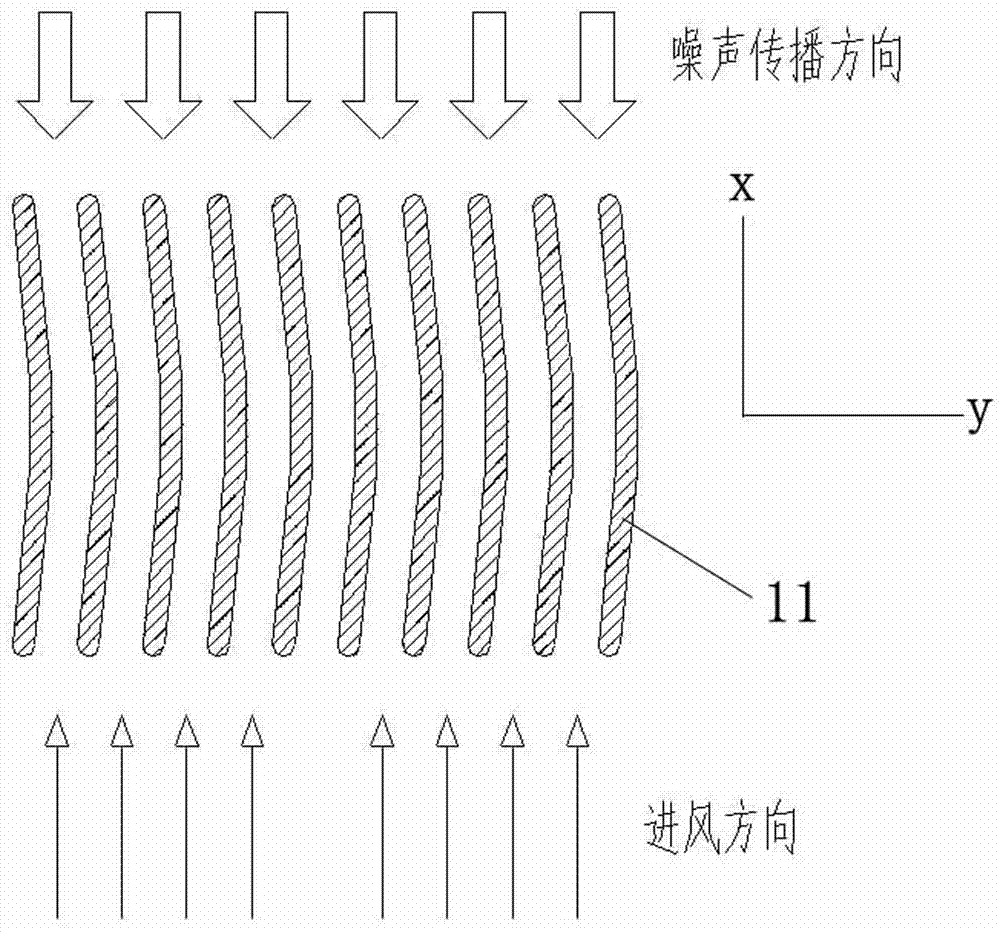

[0032] see figure 1 with Figure 4-6 .

[0033] The noise reduction device adopts multiple noise-eliminating guide vane groups 1, each noise-eliminating guide vane group 1 contains multiple noise-eliminating guide vanes 11, and there are multiple noise-eliminating guide vane groups 1 at the air inlet at the bottom of the cooling tower . There are two air inlets at the bottom of the cooling tower. The two air inlets are the front air inlet and the rear air inlet. Arranged silencing deflector group 1.

[0034] Multiple noise-eliminating guide vane groups 1 are installed at the air outlet on the top of the cooling tower. All noise-eliminating guide vanes 11 in the same noise-eliminating guide vane group 1 are installed parallel to each other and horizontally. Any adjacent two The distances between the block silencing guide vanes 11 are all equal, the silencing guide vanes group 1 at the air inlet place is arranged along the vertical direction, and the silencing guide vane gro...

Embodiment 2

[0041] see figure 2 with Figure 4-6 .

[0042] The noise reduction device adopts multiple noise-eliminating guide vane groups 1, each noise-eliminating guide vane group 1 contains multiple noise-eliminating guide vanes 11, and there are multiple noise-eliminating guide vane groups 1 at the air inlet at the bottom of the cooling tower . There are two air inlets at the bottom of the cooling tower. The two air inlets are the front air inlet and the rear air inlet. Arranged silencing deflector group 1.

[0043] Multiple noise-eliminating guide vane groups 1 are installed at the air outlet on the top of the cooling tower. All noise-eliminating guide vanes 11 in the same noise-eliminating guide vane group 1 are installed parallel to each other and horizontally. Any adjacent two The distances between the block silencing guide vanes 11 are all equal, the silencing guide vanes group 1 at the air inlet place is arranged along the vertical direction, and the silencing guide vane gr...

Embodiment 3

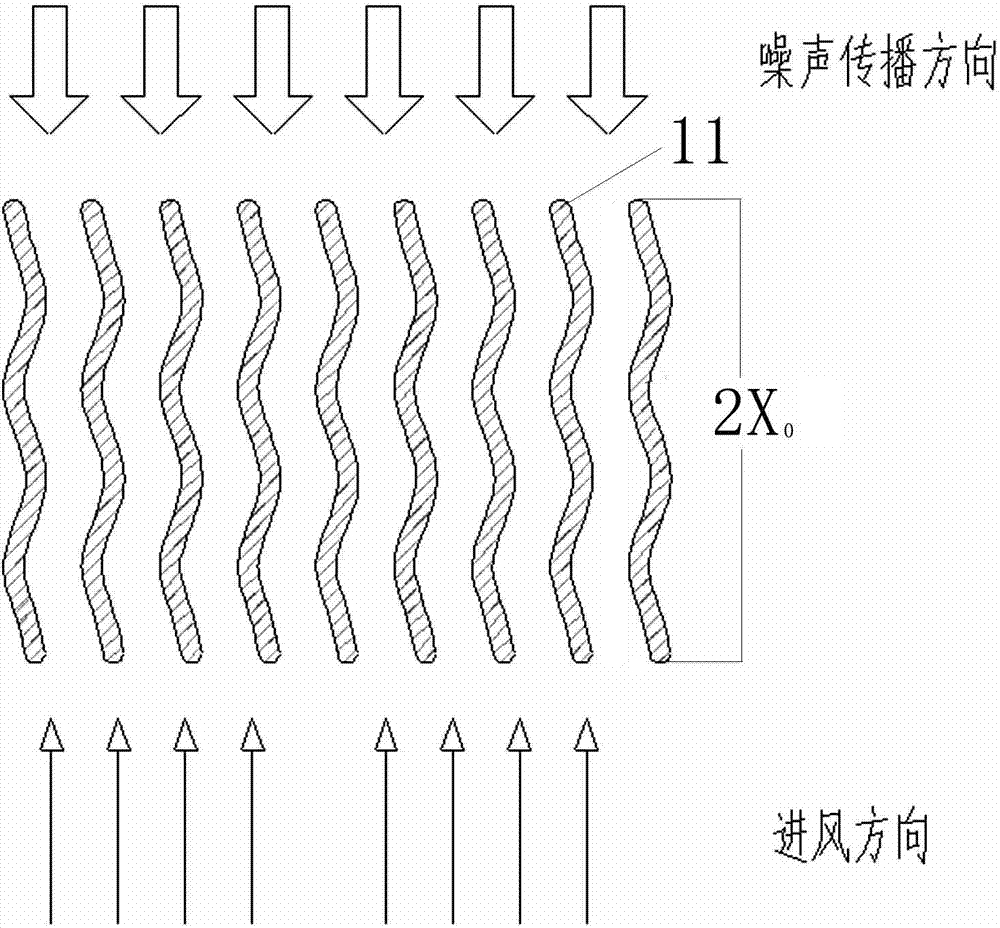

[0048] see image 3 with Figure 4-6 .

[0049] The noise reduction device adopts multiple noise-eliminating guide vane groups 1, each noise-eliminating guide vane group 1 contains multiple noise-eliminating guide vanes 11, and there are multiple noise-eliminating guide vane groups 1 at the air inlet at the bottom of the cooling tower . There are two air inlets at the bottom of the cooling tower. The two air inlets are the front air inlet and the rear air inlet. Arranged silencing deflector group 1.

[0050] Multiple noise-eliminating guide vane groups 1 are installed at the air outlet on the top of the cooling tower. All noise-eliminating guide vanes 11 in the same noise-eliminating guide vane group 1 are installed parallel to each other and horizontally. Any adjacent two The distances between the block silencing guide vanes 11 are all equal, the silencing guide vanes group 1 at the air inlet place is arranged along the vertical direction, and the silencing guide vane gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com