Semiconductor refrigerating assembly and ice cream machine

A technology of semiconductors and components, applied in the field of semiconductor refrigeration, can solve the problems of inability to achieve high-power refrigeration, affect heat transfer rate, and low heat exchange rate, and achieve high-power refrigeration, increase heat exchange area, and increase heat exchange volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

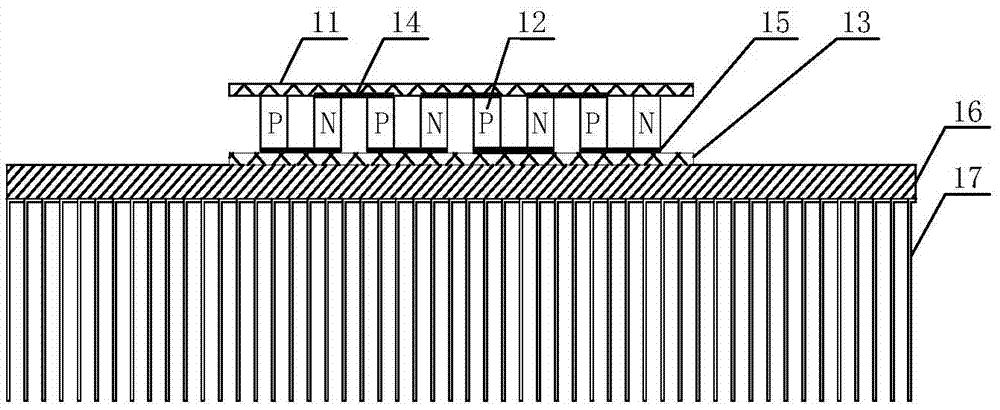

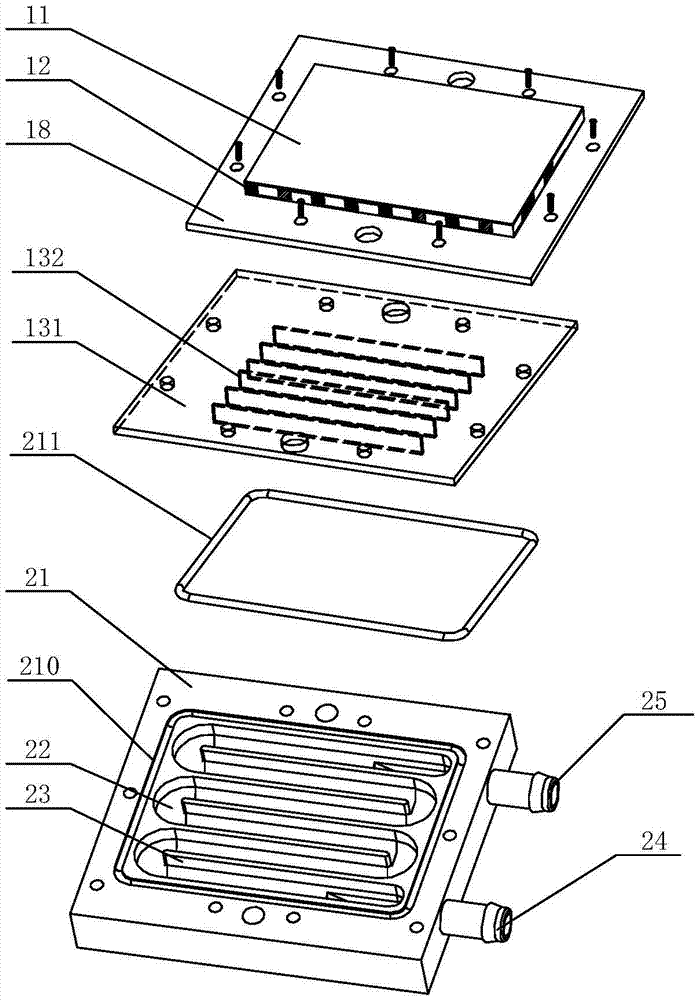

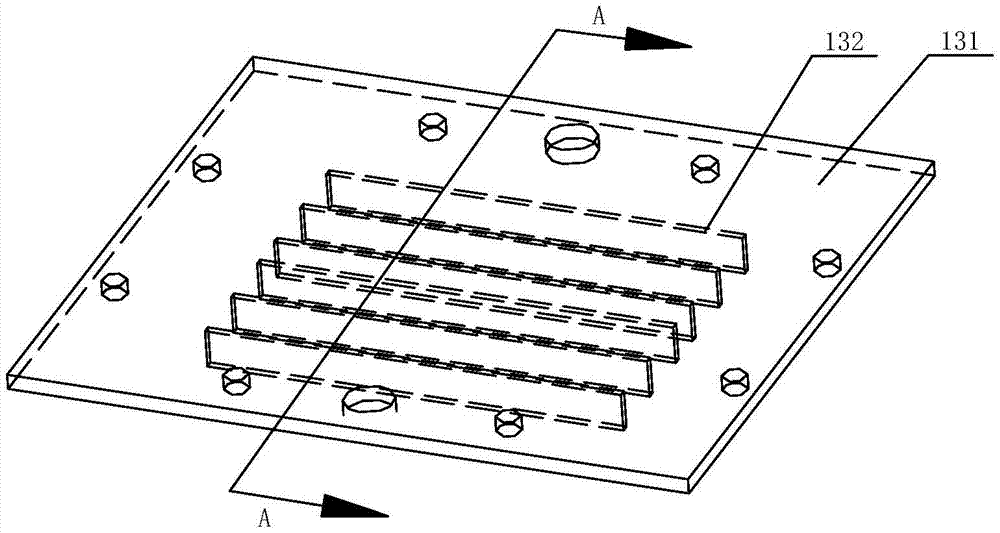

[0040] figure 2 Exploded view of the peltier refrigeration assembly provided for the embodiment of the present invention, image 3 The perspective view of the metal plate in the semiconductor refrigeration assembly provided by the embodiment of the present invention, Figure 4 for image 3 Schematic diagram of the A-A section in, Figure 5 Schematic diagram of the structure of the semiconductor refrigeration assembly provided by the embodiment of the present invention, Figure 6 for Figure 5 Schematic diagram of the B-B section in the middle. This embodiment provides a semiconductor refrigeration assembly, including: a pair of semiconductor thermocouples 12, a cold end substrate 11 connected to the cold ends of the pair of semiconductor thermocouples 12, a hot end substrate connected to the hot ends of the pair of semiconductor thermocouples 12, and a liquid cooling device.

[0041] Wherein, the cold end of the semiconductor couple pair (also called a P-N couple pair) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com