Heating grease supply device and method

A grease supply and grease storage technology, used in lubricating parts, conveying pipes/joints, mechanical equipment, etc., can solve the problems of poor heating effect of grease, poor thermal conductivity of grease, etc., to achieve efficient heating and improve volumetric efficiency , The effect of improving the gap flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

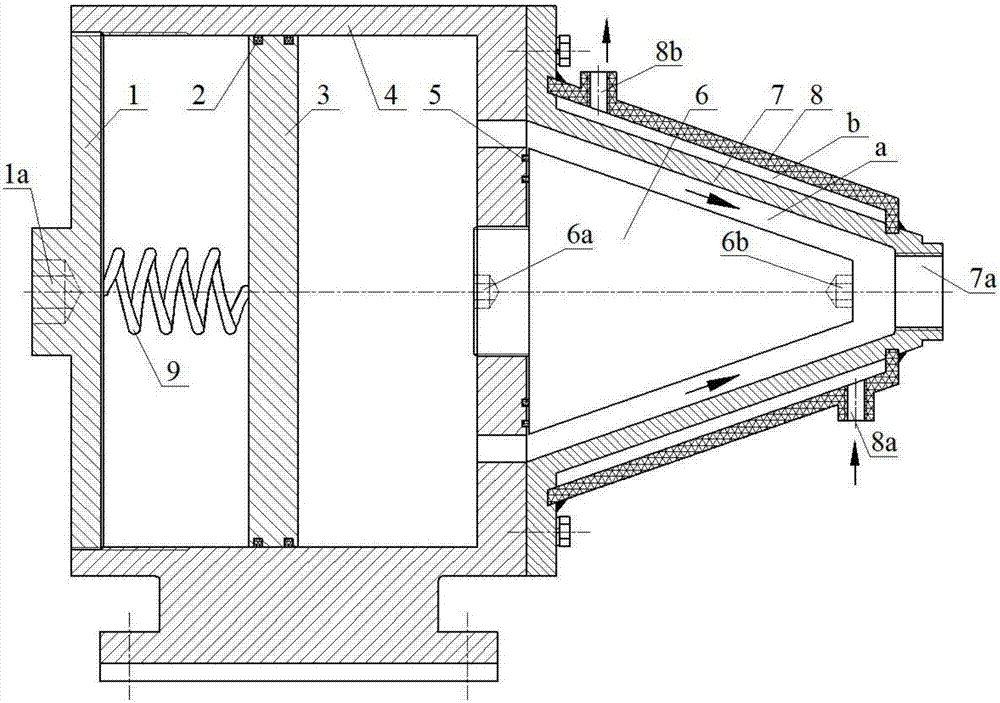

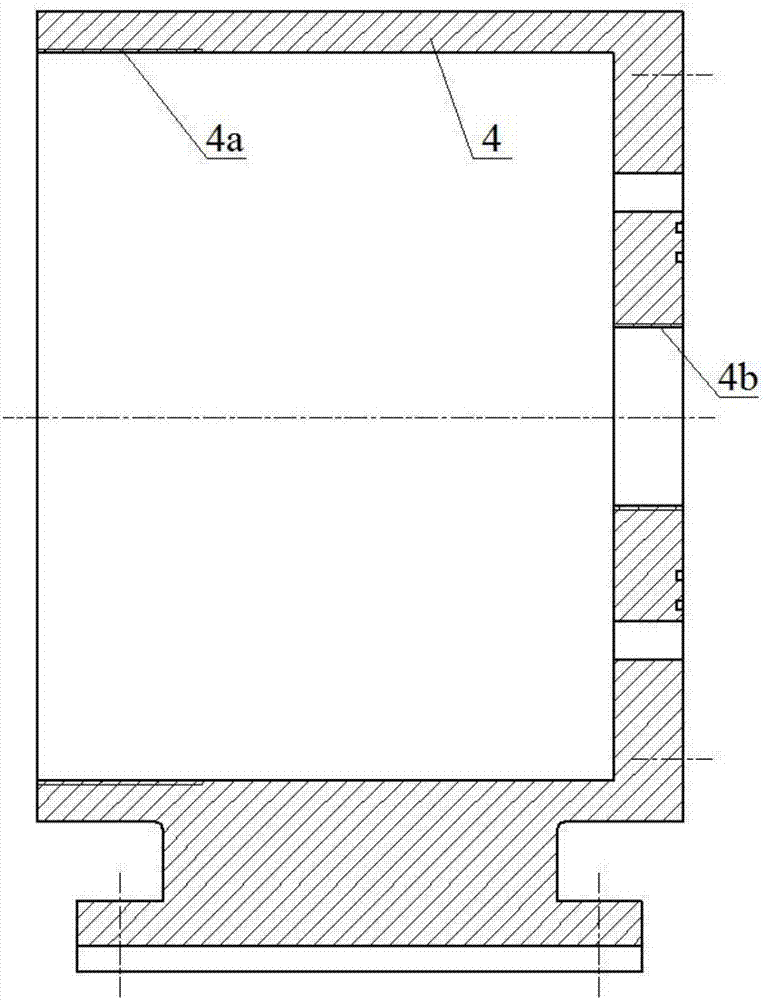

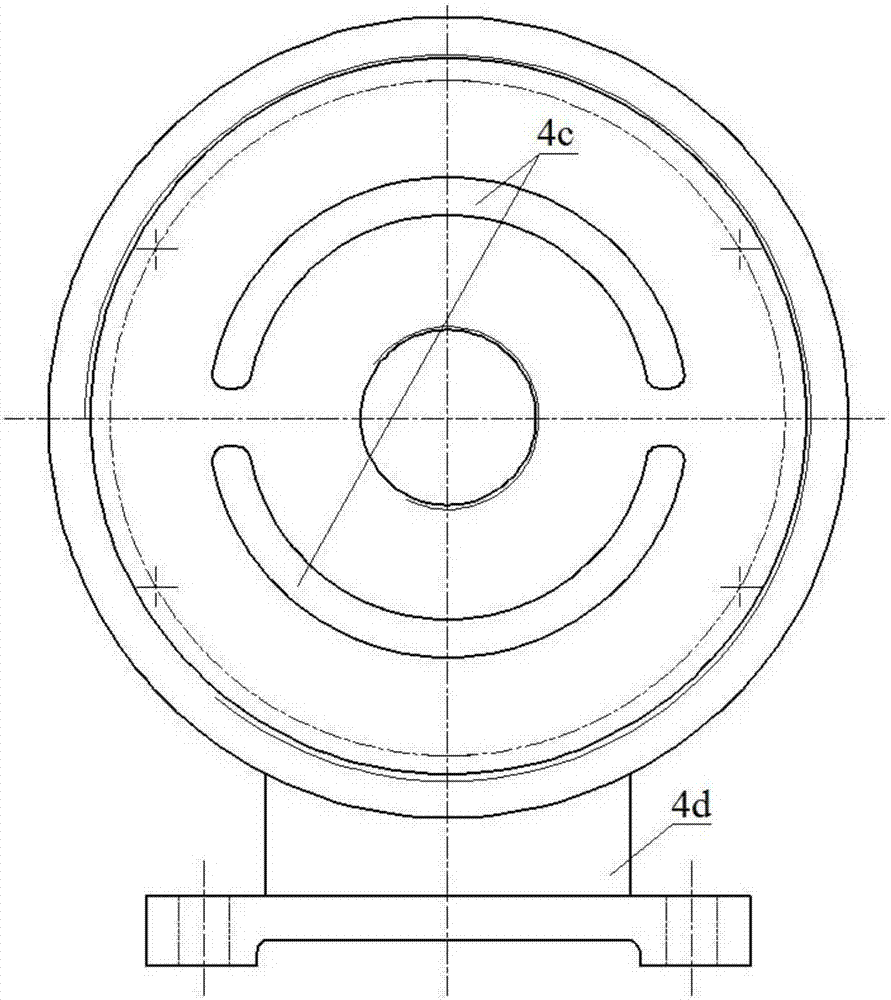

[0025] Through the description of the embodiments below, the specific implementation of the present invention includes the shape, structure, mutual position and connection relationship between the various parts, the function and working principle of each part, the manufacturing process and the operation and use method of the various components involved. etc., to make further detailed descriptions to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0026] Grease has significant thermal rheological properties. As the temperature rises, the medium viscosity of the grease decreases, and the pipeline resistance during the flow process decreases. In addition, the grease has relatively obvious wall slip characteristics. The higher the temperature, the more wall slip The more significant the effect, the more obvious the drag reduction effect on grease. Based on this, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com