Shield spiral conveyor and shield tunneling machine

A technology of screw conveyor and shield screw, which is used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of unfavorable screw conveyor arrangement and lifting, poor stability and adjustment performance, and long screw conveyor length. , to achieve the effect of small occupied space, avoiding pollution and high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

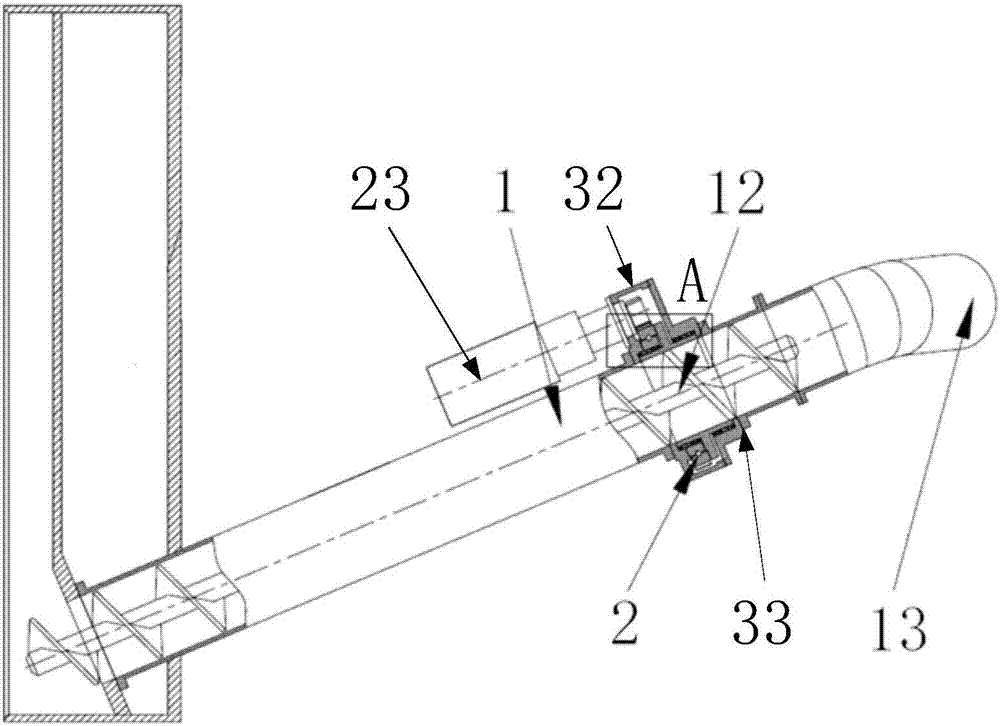

[0025] figure 1 and figure 2 The embodiment of the shield screw conveyor of the present invention is shown. The shield screw conveyor 1 includes a rotating cylinder 11, a screw shaft 12 arranged in the rotating cylinder 11 and a slag outlet 13 arranged at the rear end of the rotating cylinder 11. , the rotation of the rotating cylinder 11 drives the screw shaft 12 to transport the muck 6 backward to the slag outlet 13, and the muck 6 is discharged from the slag outlet 13. In this embodiment, the shield screw conveyor 1 includes a rotating cylinder 11 and a cylinder driving assembly 2, the rotating cylinder 11 is used to discharge the cutting muck 6, and the cylinder driving assembly 2 is used to drive the rotating cylinder 11 to rotate, The cylinder driving a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com