A chiseling device for curved concrete surface of tunnel lining tiles

A technology for tunnels and linings, which is applied to buildings and building structures, can solve the problems of long construction period, poor applicability and difficult construction, and achieve the effect of improving construction safety factor, avoiding inefficiency and improving chisel quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

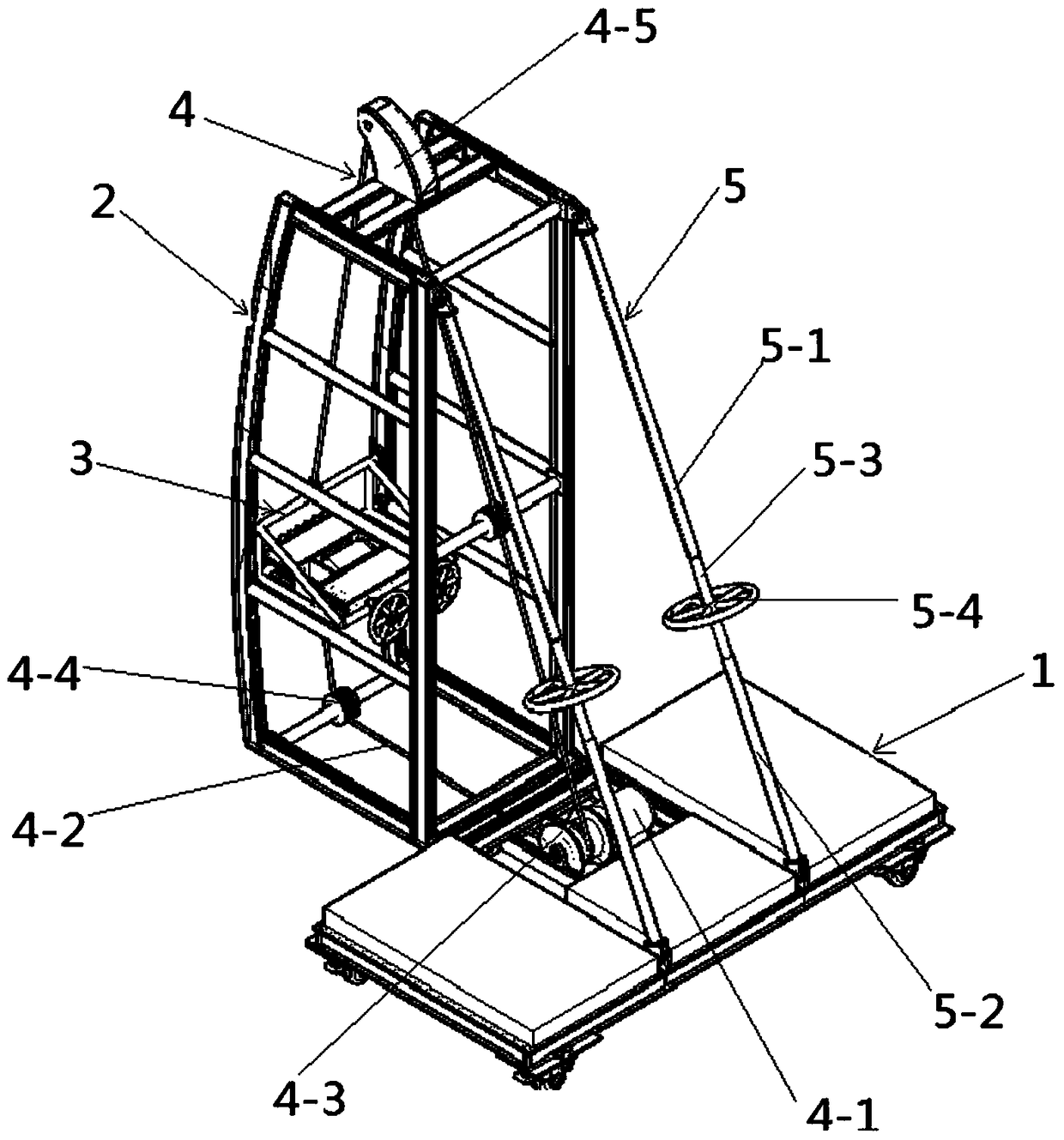

[0049] Such as figure 1 Shown, the present invention comprises running gear 1, is arranged on the working frame 2 of running gear 1 side, is installed on the chisel car 3 on the work frame 2 and is used to drive the lifting drive mechanism 4 of chisel car 3 lifting, and uses The bottom of the working frame 2 is hinged to the running gear 1 for the telescopic pull rod mechanism 5 for adjusting the distance between the working frame 2 and the curved concrete surface of the tunnel.

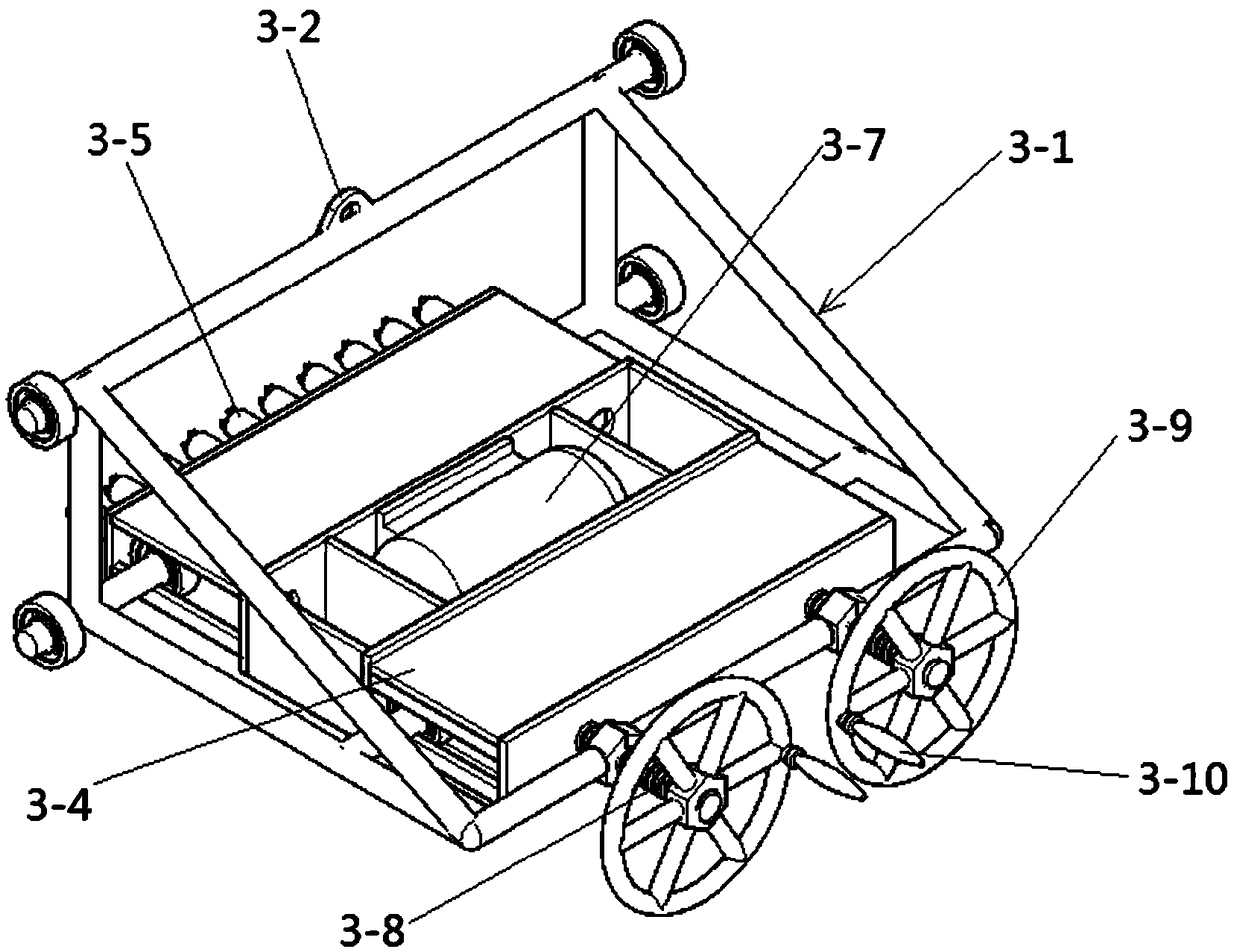

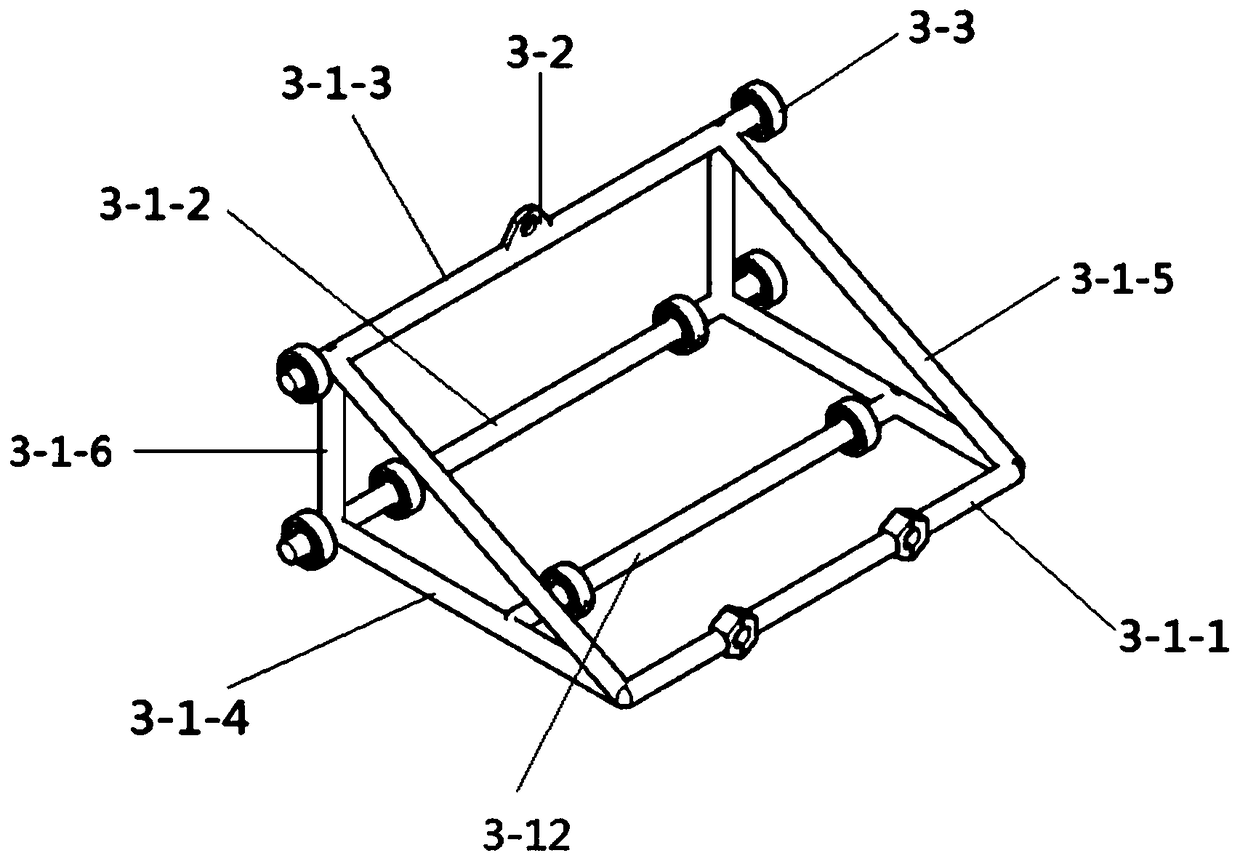

[0050] Such as figure 2 As shown, in the present embodiment, the chisel car 3 includes a car frame 3-1 and a chisel box 3-4 installed on the car frame 3-1, and a driving chisel is installed in the chisel box 3-4. The vibrating motor 3-7 that reciprocates the hair box 3-4 towards the curved concrete surface of the tunnel, the side of the chisel box 3-4 near the curved concrete surface of the tunnel is equipped with a detachable chisel head 3-5, the The side of the chisel box 3-4 away from the curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com