A kind of fast composting fermentation method

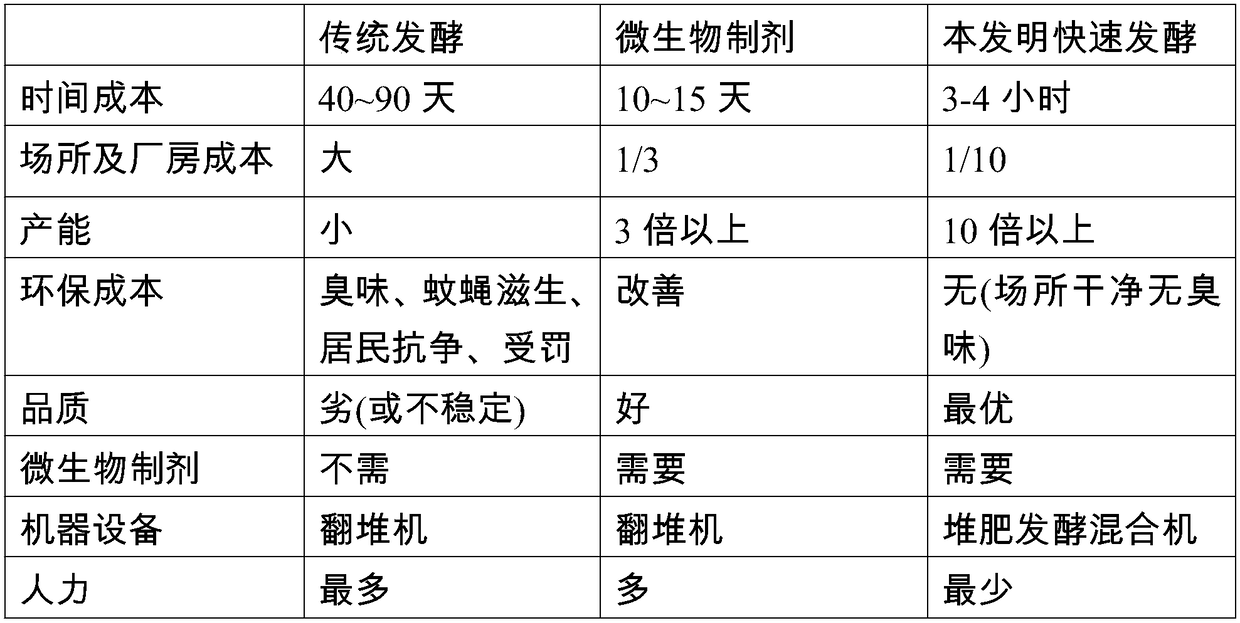

A fermentation method and composting technology, applied in the directions of organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve the problems of long fermentation time, and achieve the effects of high production efficiency, strong controllability and speeding up production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) 700kg of poultry manure and 300kg of sawdust are dropped into a composting fermentation mixer and stirred for 3 minutes, so that the carbon-nitrogen ratio of the compost material in the composting fermentation mixer is 25, and the moisture content is 50%;

[0032] (2) 7.5kg contains 1×10 6 CFU / g microbial agent of Bacillus subtilis was added to the compost fermentation mixer mentioned above, the rotor speed was controlled at 25 rpm, and the stirring continued for 1.5 hours. After the temperature of the material rose to 45°C, 7.5 kg containing 1×10 6 CFU / g microbial agent of Bacillus coagulans to the compost fermentation mixer, control the rotor speed at 26 rpm, and continue to stir for 2 hours. After the temperature of the material rises to 60°C, it is cooled by the conveying system, and the fermentation is completed to obtain organic fertilizer. .

Embodiment 2

[0034] (1) Put 700kg of poultry manure, 250kg of stalks and 50kg of sawdust into a composting fermentation mixer and stir for 2 minutes, so that the carbon-nitrogen ratio of the compost material in the composting fermentation mixer is 23, and the moisture content is 45%;

[0035] (2) 7.5kg contains 1×10 9CFU / g microbial agent of Bacillus coagulans was added to the above-mentioned compost fermentation mixer, the rotor speed was controlled at 30 rpm, and the stirring was continued for 1 hour. After the temperature of the material rose to 50°C, 7.5kg containing 1×10 9 CFU / g microbial agent of Bacillus coagulans to the compost fermentation mixer, control the rotor speed at 29 rpm, and continuously stir for 2 to 3 hours. After the temperature of the material rises to 70°C, it is cooled by the conveying system and the fermentation is completed. Organic Fertilizer.

Embodiment 3

[0037] (1) 700kg of poultry manure, 150kg of sawdust and 150kg of wheat stalks are put into a composting fermentation mixer and stirred for 2 minutes, so that the carbon-nitrogen ratio of the compost material in the composting fermentation mixer is 30, and the moisture content is 40%;

[0038] (2) 3.75kg contains 1×10 7 CFU / g Bacillus subtilis and Bacillus coagulans mixed at a ratio of 1:1 are added to the above-mentioned compost fermentation mixer, the rotor speed is controlled at 27 rpm, and the stirring is continued for 1.2 hours. After the temperature of the material rises to 47°C , add again 3.75kg containing 1×10 7 CFU / g Bacillus subtilis and Bacillus coagulans mixed in a ratio of 1:2 to the compost fermentation mixer, control the rotor speed at 27 rpm, and continue to stir for 2.6 hours. After the temperature of the material rises to 65°C, The conveying system is cooled, and the fermentation is completed to obtain organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com