Manufacturing method of antique floor with sawtooth marks and milling machine for antique floor with sawtooth marks

A technology of antique flooring and processing methods, applied in wood processing appliances, special forming/shaping machines, manufacturing tools, etc., can solve the problems of not being suitable for mass production and low sawing efficiency, and achieve realistic effects and simple structures , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below through embodiments and in conjunction with the accompanying drawings.

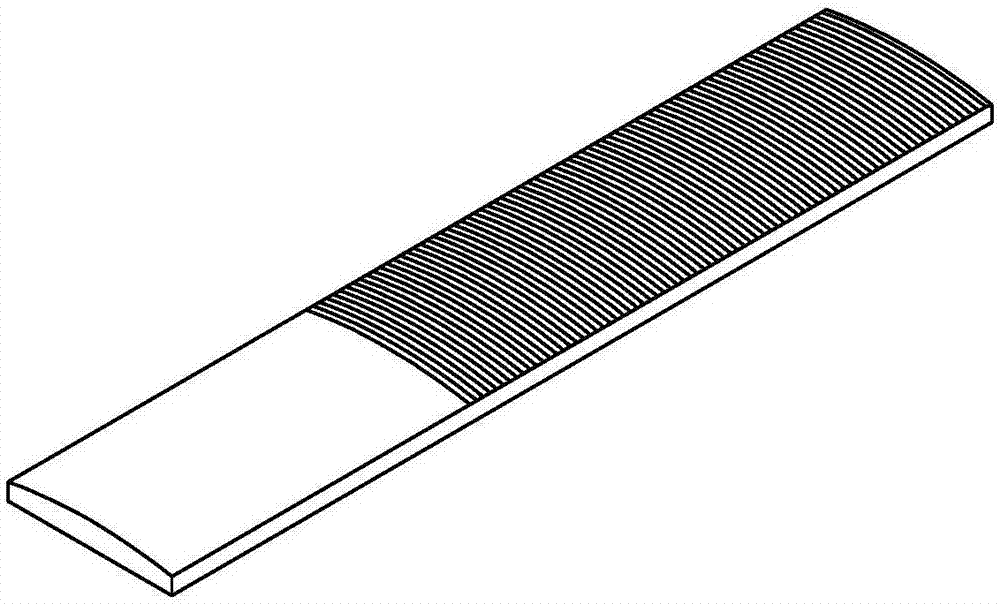

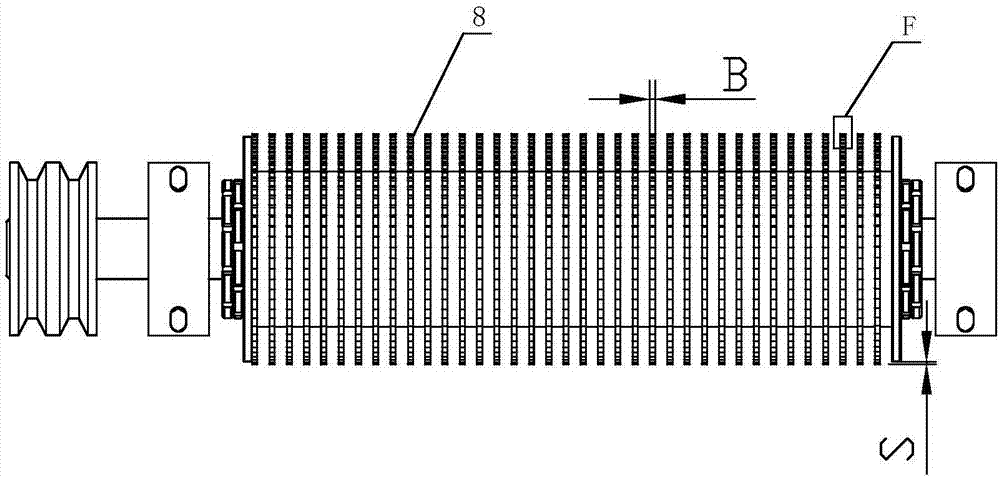

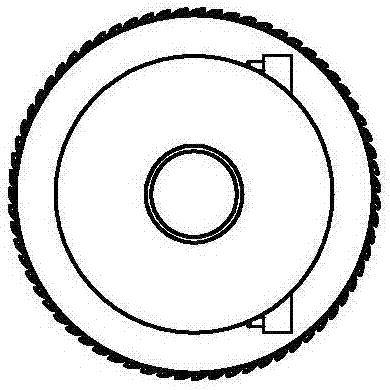

[0034] The processing method of the antique floor includes making a long strip of wooden floor blank 1, and processing strips on the surface of the wooden floor blank 1 to imitate the saw marks left by sawing with a saw blade. The wooden floor can also be simulated for several years or dozens of years. After a year, along the short side of the floor, the bending deformation effect of arching or concave on the surface is as follows: figure 1 shown. The saw marks are formed by axially installing a plurality of disc milling cutters 2 on the rotating cutter shaft 2. figure 2 , image 3 , Figure 4 As shown, the surface of the wood floor blank 1 is milled by the knife row 8, and the blade of the disc milling cutter 3 is flat as Figure 5 Single angle milling cutters as shown or beveled Figure 6 shown. On the milling surface of the wood floor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com