Manufacturing method of electronic circuit board and electronic circuit board obtained by the manufacturing method

一种电路基板、制造方法的技术,应用在印刷电路制造、软性印刷电路板、印刷电路等方向,达到贮存稳定性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

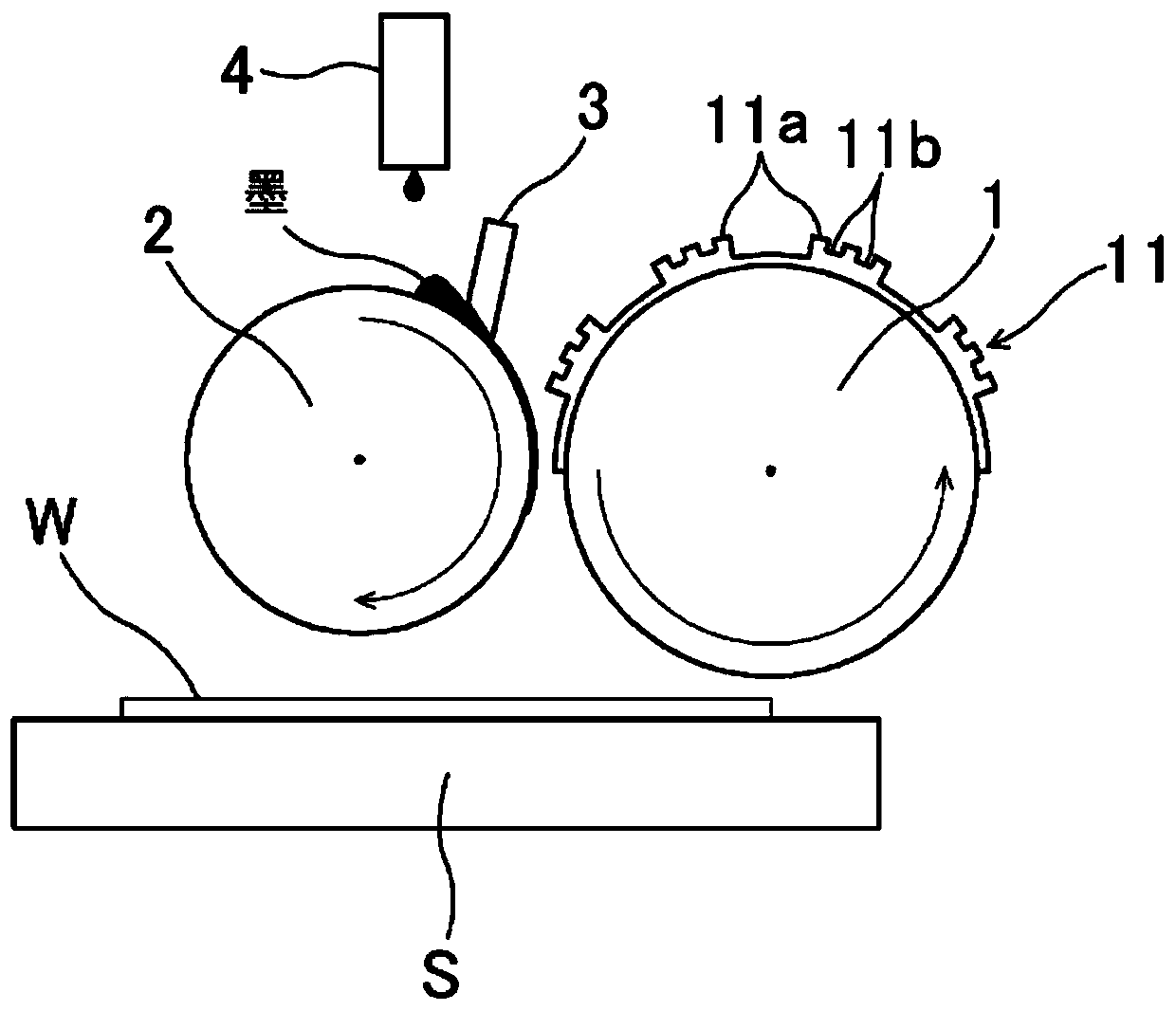

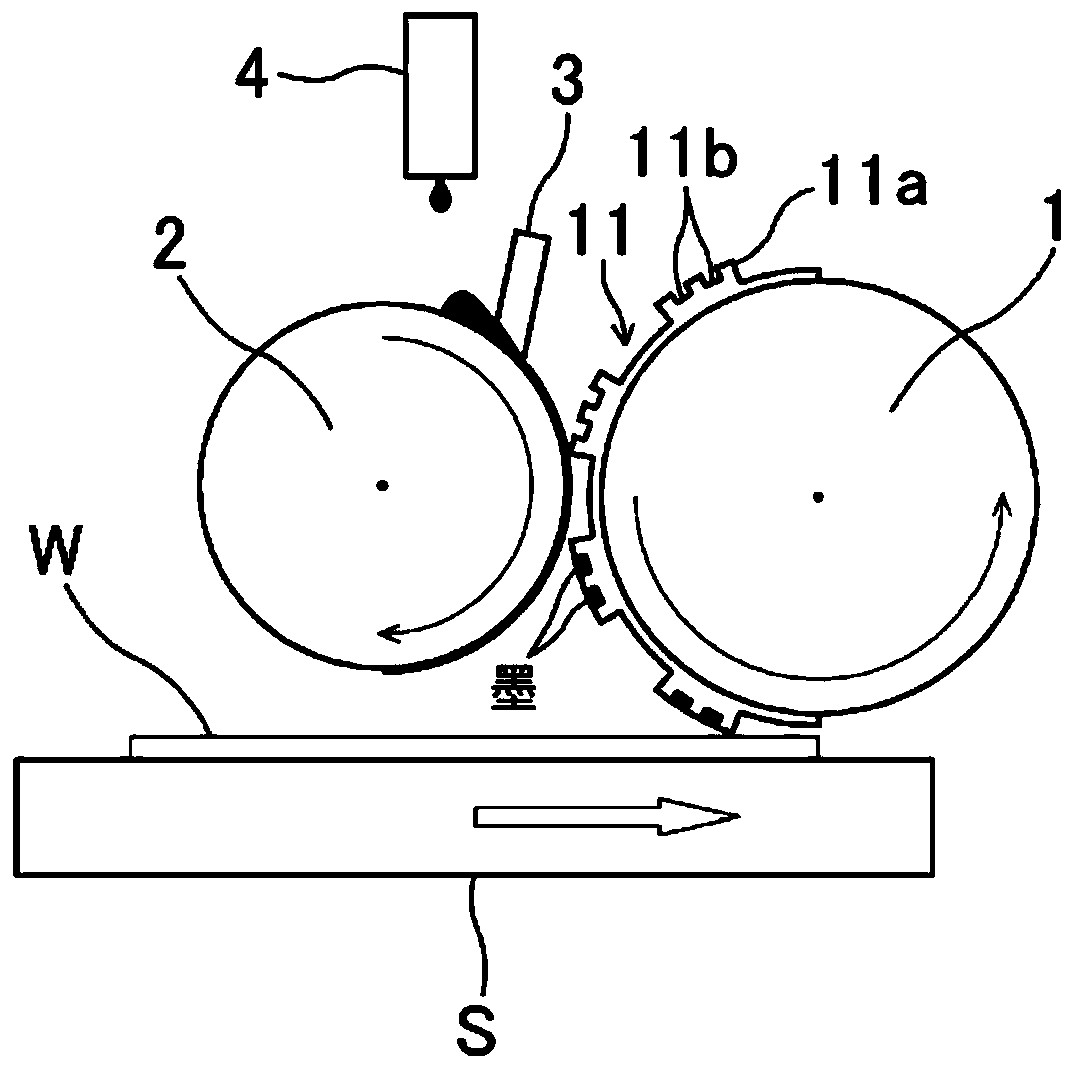

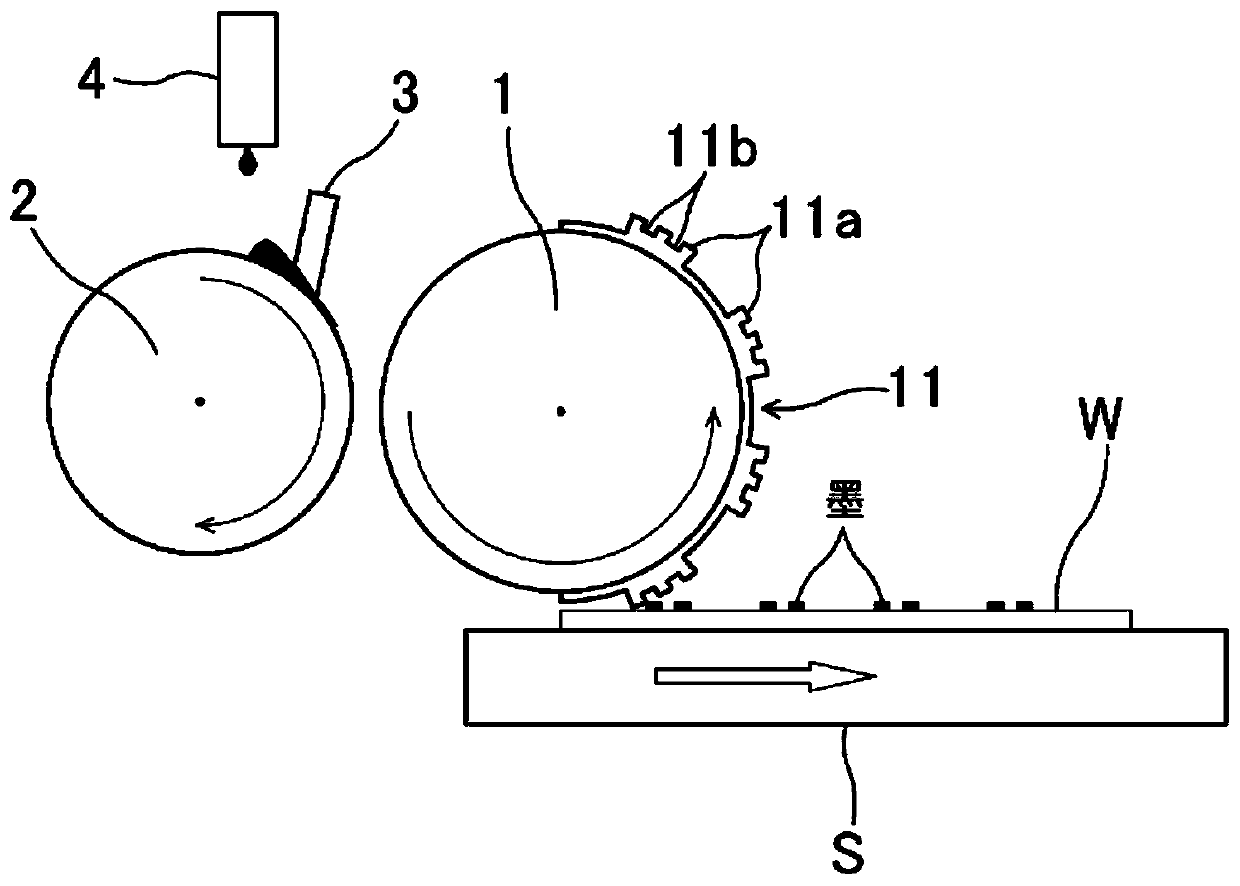

Method used

Image

Examples

Embodiment 1

[0102] Under the above-mentioned conditions, utilize the flexographic printing machine on the same area of the surface (printed surface) of the base material (photo paper), the nano-ink composition is coated continuously 1 time or 3 times, 6 times or more respectively. Lamination was performed, and the substrate was left to air-dry for 60 minutes at room temperature (23° C.) in the atmosphere to obtain an electronic circuit board of “Example 1” in which an electronic circuit was transferred and formed on a base material.

Embodiment 2

[0104] Except using PET film (coating ink-receiving layer) as base material, utilize flexographic printing machine in the same area of base material surface with nano-ink composition to be coated continuously 1 time respectively with above-mentioned Example 1 After 3 times and 6 times, it was left to stand under the atmosphere at room temperature (23° C.) for 60 minutes to obtain the electronic circuit board of “Example 2”.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com