Multifunctional electric push rod

An electric push rod, multi-functional technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of mold processing accuracy, failure to use normally, poor dimensional stability of electric push rods, etc., to improve the stability of force Performance and reliability, improved positional stability, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

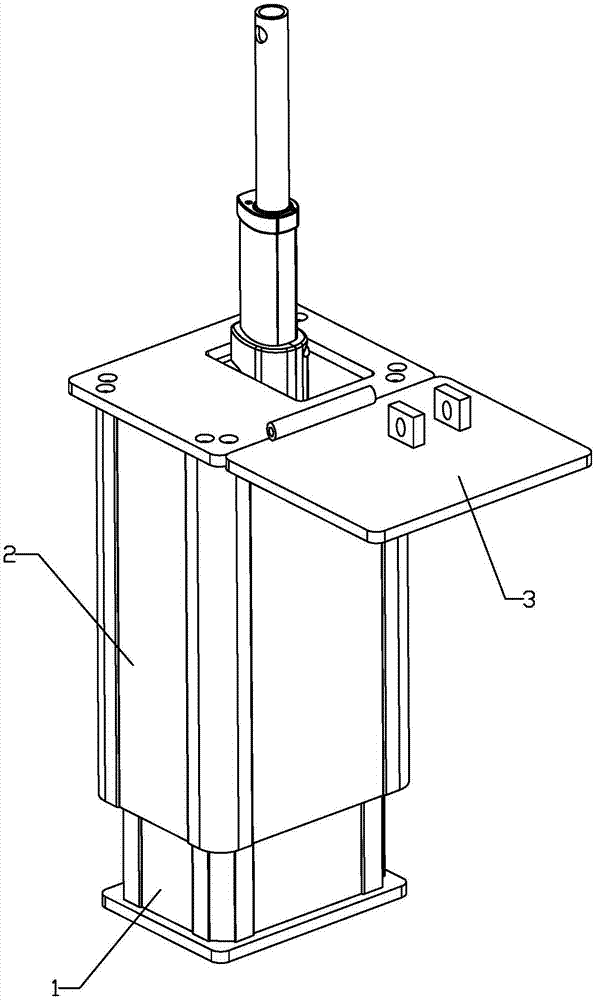

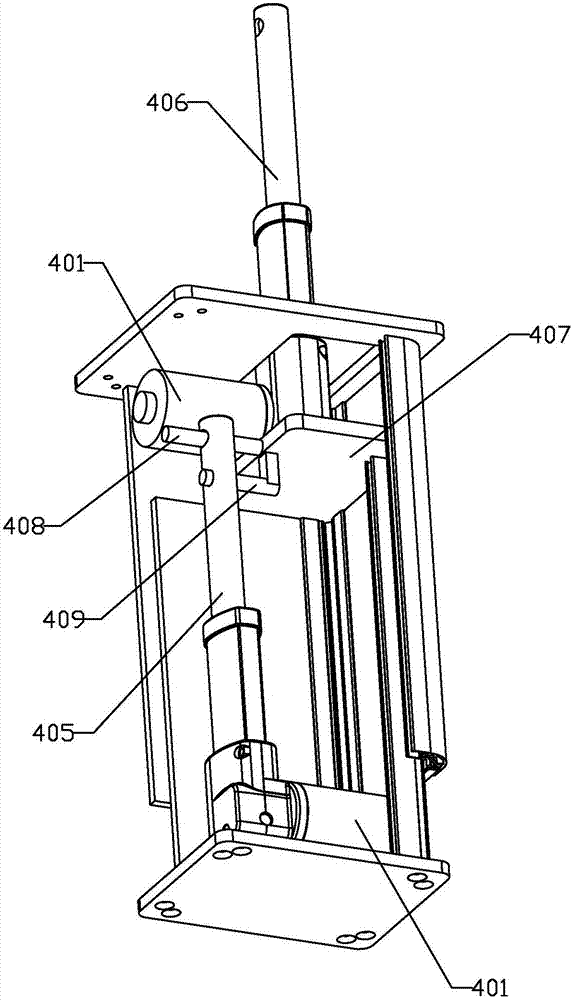

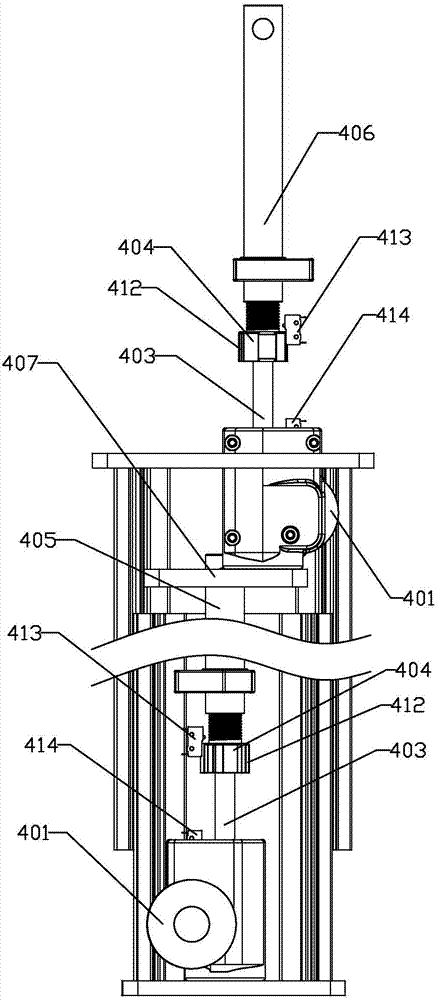

[0027] The present invention will be further described below in conjunction with accompanying drawing, according to Figure 1 to Figure 6 As shown, the multifunctional electric push rod of the present invention mainly includes a mounting base 1, a transmission base 2 and a telescopic transmission assembly. Wherein, the transmission seat 2 is arranged on the installation seat 1 and is slidably connected with the installation seat 1; The telescopic transmission assembly includes a directional transmission mechanism and a direction-changing transmission mechanism. Among them, the directional transmission mechanism is set in the mounting seat 1, which is used to produce a directional telescopic transmission effect on the load on the transmission seat 2; A change in direction produces a steering effect. A flipping part 3 is arranged on the top of the transmission seat 2, and the fixed end of the reversing transmission mechanism is hinged with the transmission seat 2, and the mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com