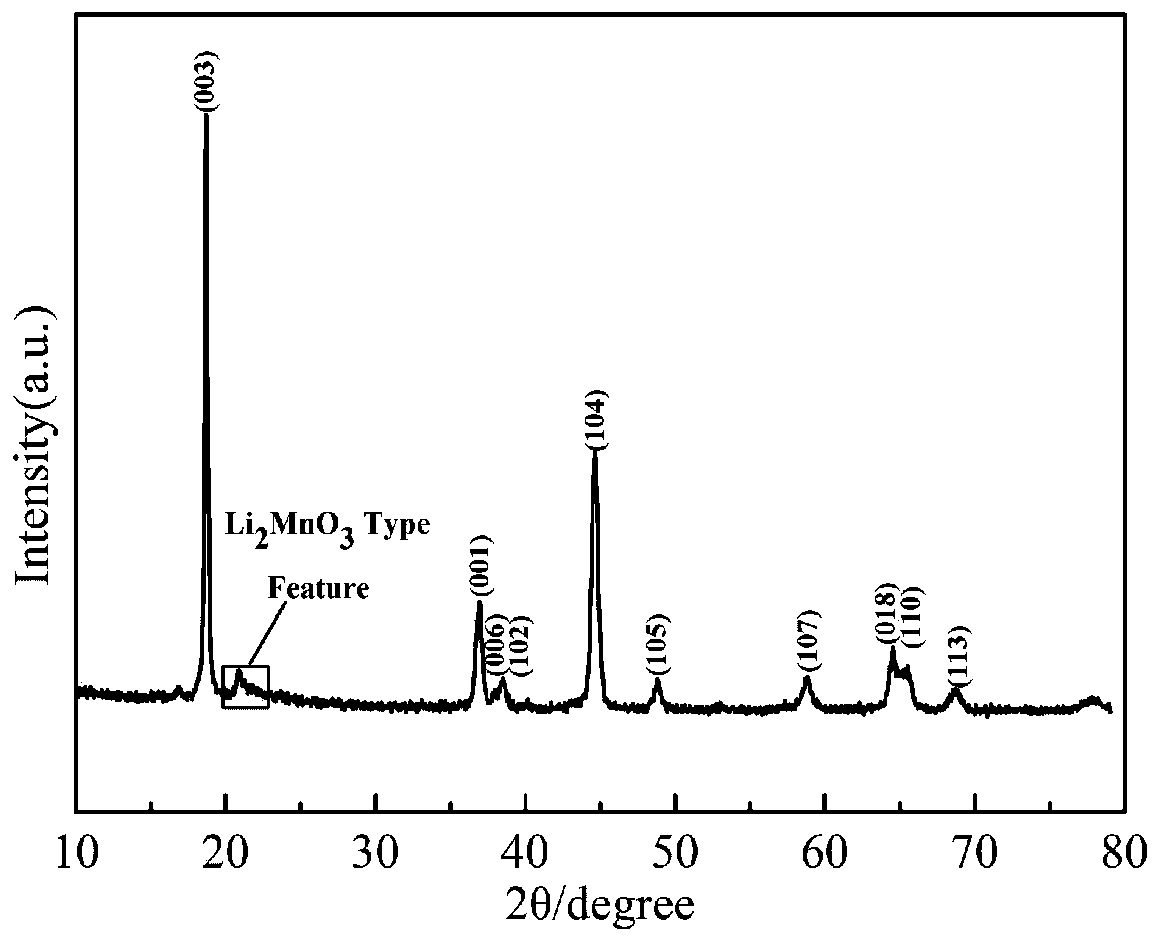

A preparation method of lithium-rich manganese-based cathode material with double controllable morphology and size

A lithium-rich manganese-based, cathode material technology, used in positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of insufficient rate performance, low first coulomb efficiency, and poor cycle performance, and achieve excellent rate performance. Wide-ranging and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) First, add the soluble transition metal manganese acetate, nickel acetate, and cobalt acetate into the mixed solvent of water, ethanol and ethylene glycol with a volume ratio of 1:3:1 at a molar ratio of 4:1:1 to prepare a total A homogeneous solution A with a transition metal ion concentration of 0.4mol / L; then add a certain amount of CTAB to the solution and stir evenly, wherein the molar ratio of surfactant to total metal ions is 0.5:1;

[0040] (2) soluble sodium oxalate that the amount of total metal ions is 2 times is dissolved in water, ethanol and ethylene glycol mixed solvent (the three are mixed in equal volume) and is formulated into solution B, wherein the volume ratio of solution B and solution A is 1:1;

[0041] (3) Add solution B prepared in step (2) dropwise to solution A at a rate of 1 mL / min, react for 2 h under sealed conditions, after the reaction is completed, filter the resulting product and wash it repeatedly with deionized water and ethanol, ...

Embodiment 2

[0046] (1) First, add the soluble transition metal manganese chloride, nickel chloride, and cobalt chloride into the mixed solvent of water, ethanol and ethylene glycol with a volume ratio of 3:13:1 at a molar ratio of 4:1:1, Prepare a homogeneous solution A with a total transition metal ion concentration of 0.1mol / L; then add a certain amount of SDBS to the solution and stir evenly, wherein the molar ratio of surfactant to total metal ions is 1:1.

[0047] (2) Sodium hydrogen oxalate of 1.5 times of the amount of total metal ion substances is dissolved in water, ethanol and ethylene glycol mixed solvent (the three are mixed in equal volume) and is formulated into solution B, wherein the volume ratio of solution B and solution A is 1:1;

[0048] (3) Add solution B prepared in step (2) dropwise to solution A at a rate of 3 mL / min, and react for 6 h under sealed conditions. After the reaction is completed, the resulting product is filtered and washed repeatedly with deionized wa...

Embodiment 3

[0053] (1) First, add the soluble transition metal manganese chloride, nickel nitrate, and cobalt chloride into the mixed solvent of water and ethylene glycol with a volume ratio of 3:5 at a molar ratio of 4:1:1 to prepare a total transition metal A homogeneous solution A with an ion concentration of 0.5 mol / L; then add a certain amount of CTAB to the solution and stir evenly, wherein the molar ratio of surfactant to total metal ions is 0.75:1.

[0054] (2) soluble sodium oxalate that the amount of total metal ions is 2 times is dissolved in water, ethanol and ethylene glycol mixed solvent (the three are mixed in equal volume) and is formulated into solution B, wherein the volume ratio of solution B and solution A is 1:1;

[0055] (3) Add solution B prepared in step (2) dropwise to solution A at a rate of 10mL / min per drop, and react for 1h under sealed conditions. After the reaction is completed, filter the resulting product and repeat with deionized water and ethanol. Wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com