High voltage-low voltage combined busbar and manufacture method of same

A manufacturing method and composite row technology, applied in the direction of conductors, conductor/cable insulation, insulated cables, etc., can solve problems such as interference, cumbersome wiring harness connections, and low efficiency, and achieve high reliability, compact structure, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

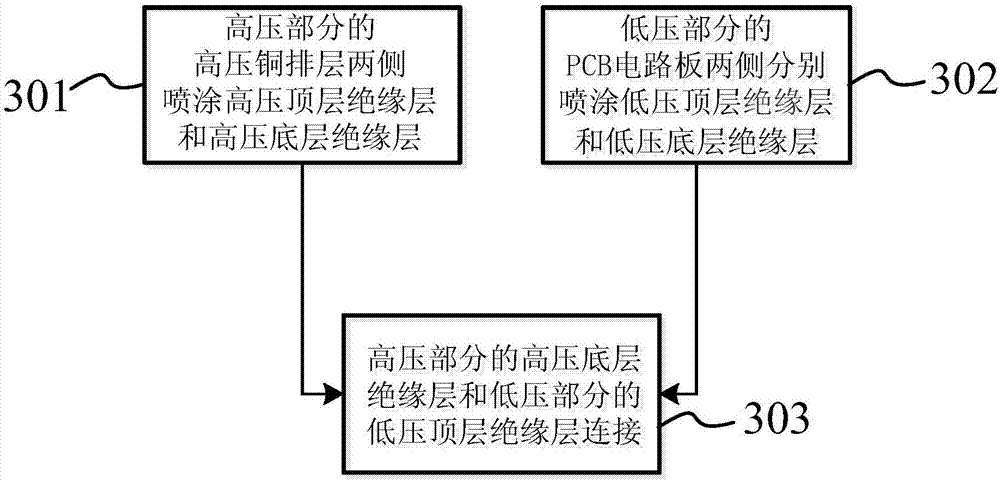

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described below based on examples, but it should be noted that the present invention is not limited to these examples. In the following detailed description of the invention, some specific details are set forth in detail. However, the present invention can be fully understood by those skilled in the art about the parts that are not described in detail.

[0040] In addition, those of ordinary skill in the art should understand that the provided drawings are only for illustrating the objects, features and advantages of the present invention, and the drawings are not actually drawn to scale.

[0041] At the same time, unless the context clearly requires, the words "include", "include" and other similar words in the entire specification and claims should be interpreted as an inclusive meaning rather than an exclusive or exhaustive meaning; that is, "include but not limited to the meaning of ".

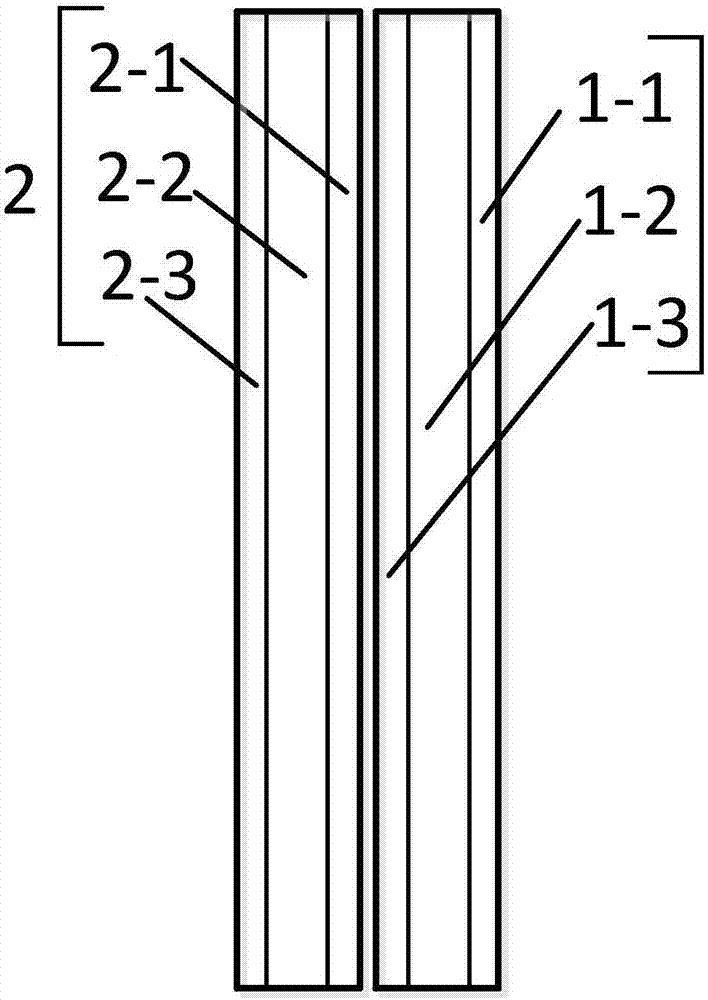

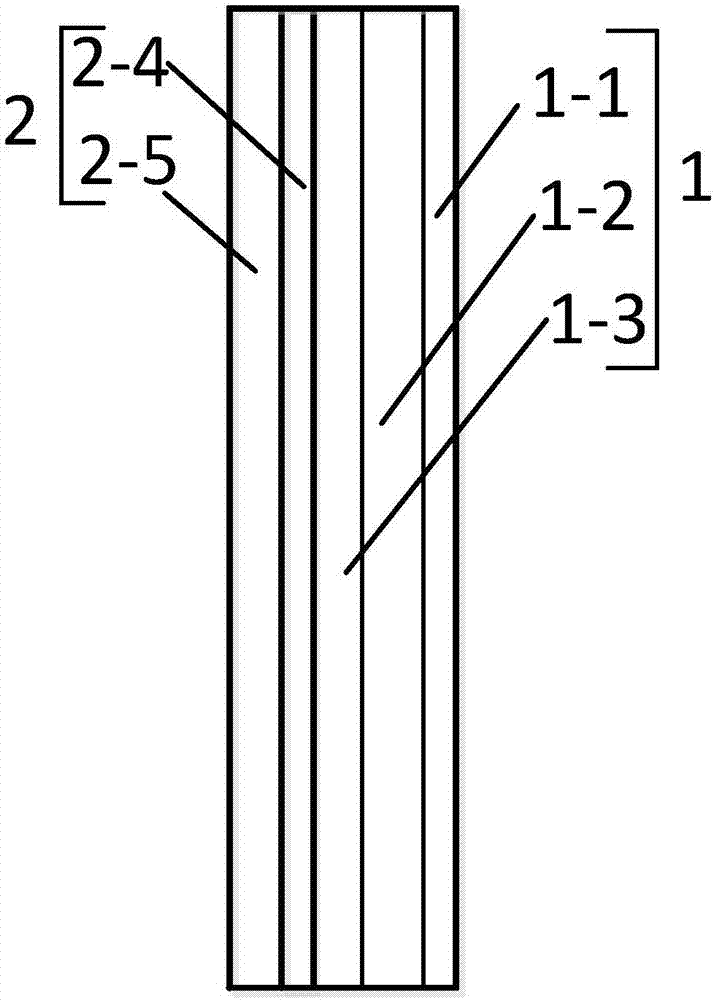

[0042] figure 1 It is a schematic diagram of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com