Built-in self-test circuit, built-in self-test system and built-in self-test method for flash memory

A built-in self-test, flash memory technology, applied in static memory, instruments, etc., can solve the problem of difficulty in flash memory testing, and achieve the effect of short test time, simple test process, and reduction of the number of pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

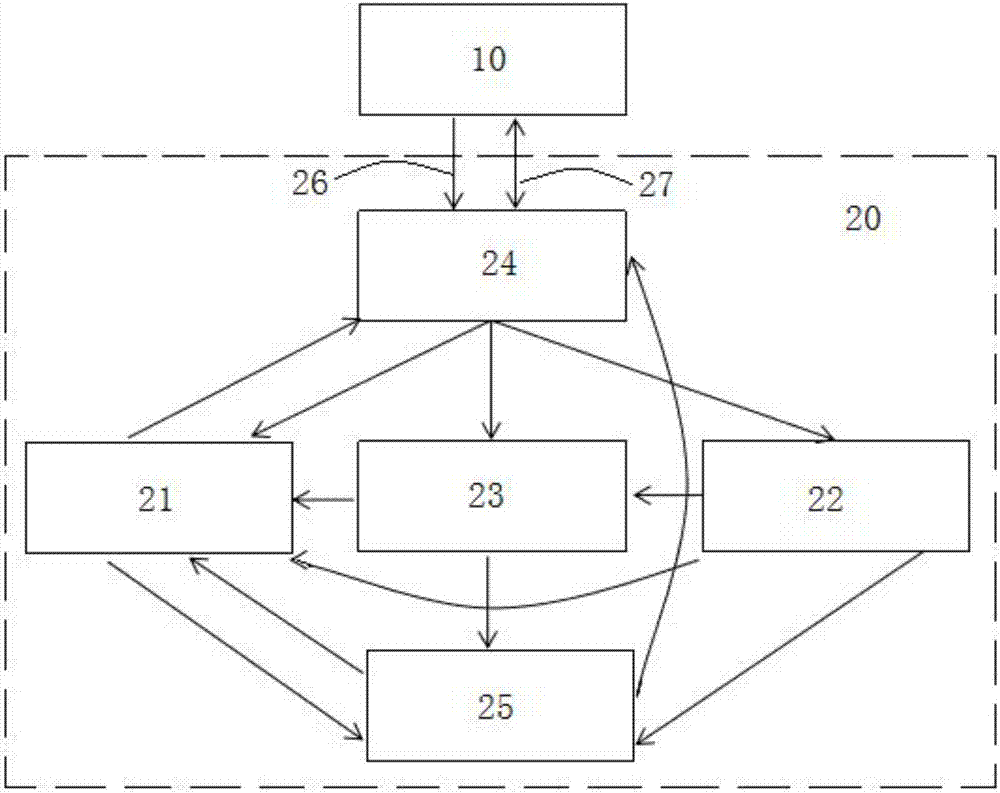

[0055] This embodiment provides a built-in self-test circuit for flash memory, the built-in self-test circuit 20 for flash memory is connected between the test machine 10 and the test flash memory, the built-in self-test circuit for flash memory The circuit 20 includes a self-reading test module 21, a self-erasing test module 22, a self-programming test module 23 and a command conversion module 24, wherein: the self-reading test module 21 is used to test the read operation of the flash memory, and Send the read test result to the command conversion module 24; the self-erasing test module 22 is used to test the erase operation of the flash memory, and send the erase test result to the command conversion module 24; Self-programming test module 23 is used for testing the programming operation of described flash memory, and programming test result is sent to described command conversion module 24; Described command conversion module 24 is used for sending the test order that descri...

Embodiment 2

[0066] This embodiment provides a built-in self-test system for flash memory. The built-in self-test system for flash memory includes a test machine 10 and a built-in self-test circuit 20 for flash memory. The built-in self-test circuit 20 is connected between the test machine 10 and the test flash memory; the built-in self-test circuit 20 for the flash memory includes a self-reading test module 21, a self-erasing test module 22, a self-programming test Module 23 and command conversion module 24, wherein: the test machine is used to send a test command to the command conversion module; the command conversion module is used to send the test command input by the test machine to the self-reading Get the test module, the self-erasing test module and the self-programming test module; the self-reading test module 21 is used to test the read operation of the flash memory, and send the read test result to the command conversion Module 24; the self-erase test module 22 is used to test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com