Full-automatic pulverized coal sampling and analyzing meter

A sampling analysis, fully automatic technology, applied in the direction of particle size analysis, analysis materials, particles and sedimentation analysis, etc., can solve the problems of difficulty in guaranteeing analysis time, adverse effects on the health of operators and the surrounding environment, and poor measurement accuracy, so as to improve accuracy The effect of improving efficiency, improving analysis work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

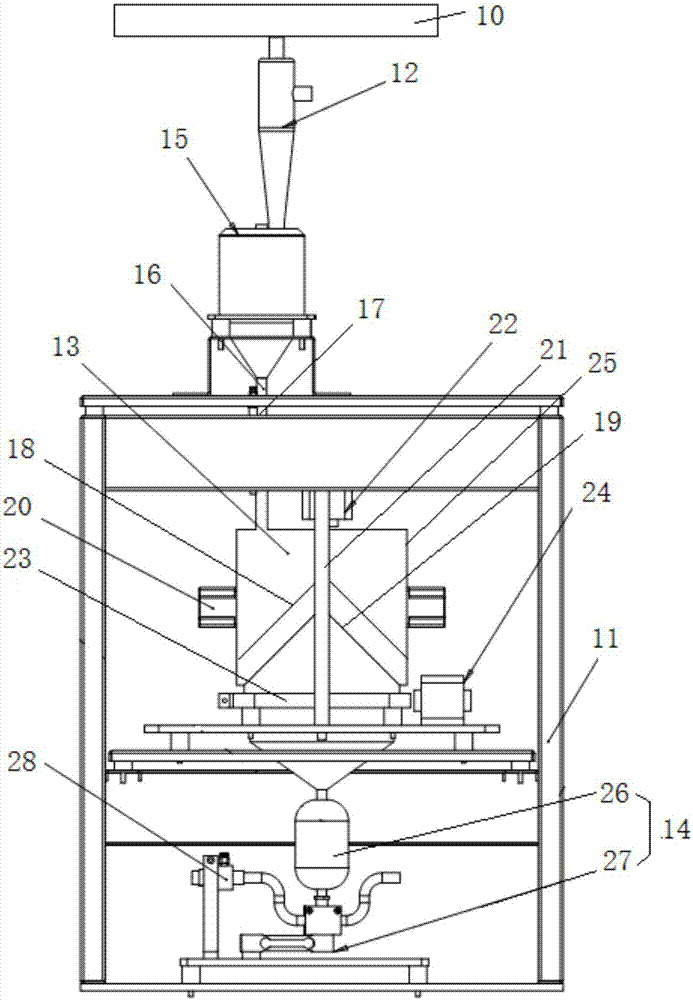

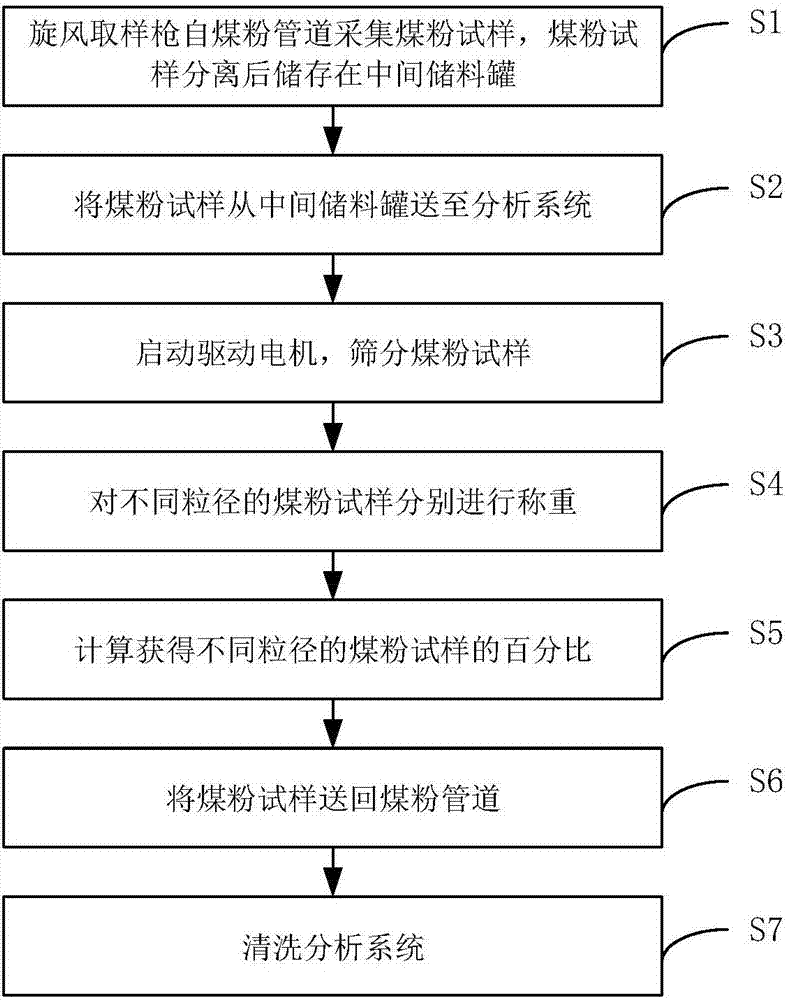

[0022] Such as figure 1 As shown, the automatic pulverized coal sampling analyzer includes a bracket 11, a sampler, an analysis system 13, a control unit and a weighing device, and the sampler and the analysis system 13 are fixed on the bracket 11 sequentially from top to bottom. Wherein, the sampler is fixed on the top of the support 11, and is used to extract the pulverized coal sample from the pulverized coal pipeline. The output port of the sampler is connected with the input port of the analysis system 13, and the pulverized coal sample collected by the sampler 12 passes through the analysis system. The input port of 13 enters analysis system 13. The analysis system 13 classifies the pulverized coal samples according to different particle sizes, the weighing device is used to weigh the pulverized coal samples of different particle sizes, and the control unit is used to control the operation of the sampler, the analysis system 13 and the weighing device.

[0023] The samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com