Oil-gas well casing wear test bed

A wear test, oil and gas well technology, applied in the direction of testing wear resistance, etc., can solve the problems of difference between test results and actual conditions, inability to change other parameters, inability to adjust eccentricity, etc., to achieve compact structure, convenient processing and manufacturing, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

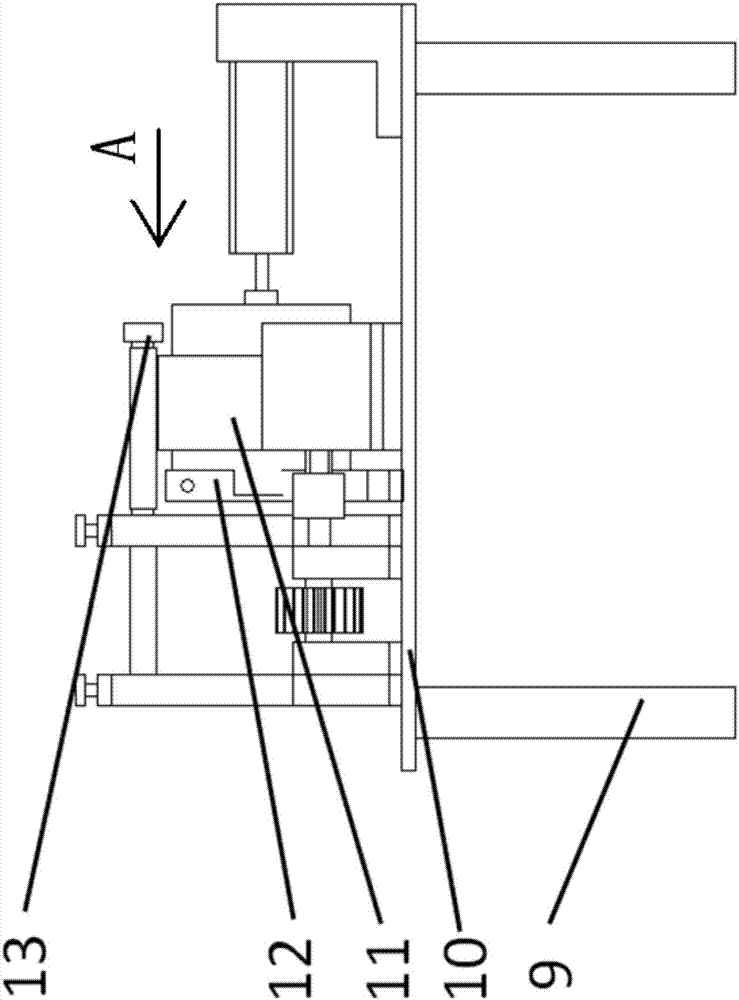

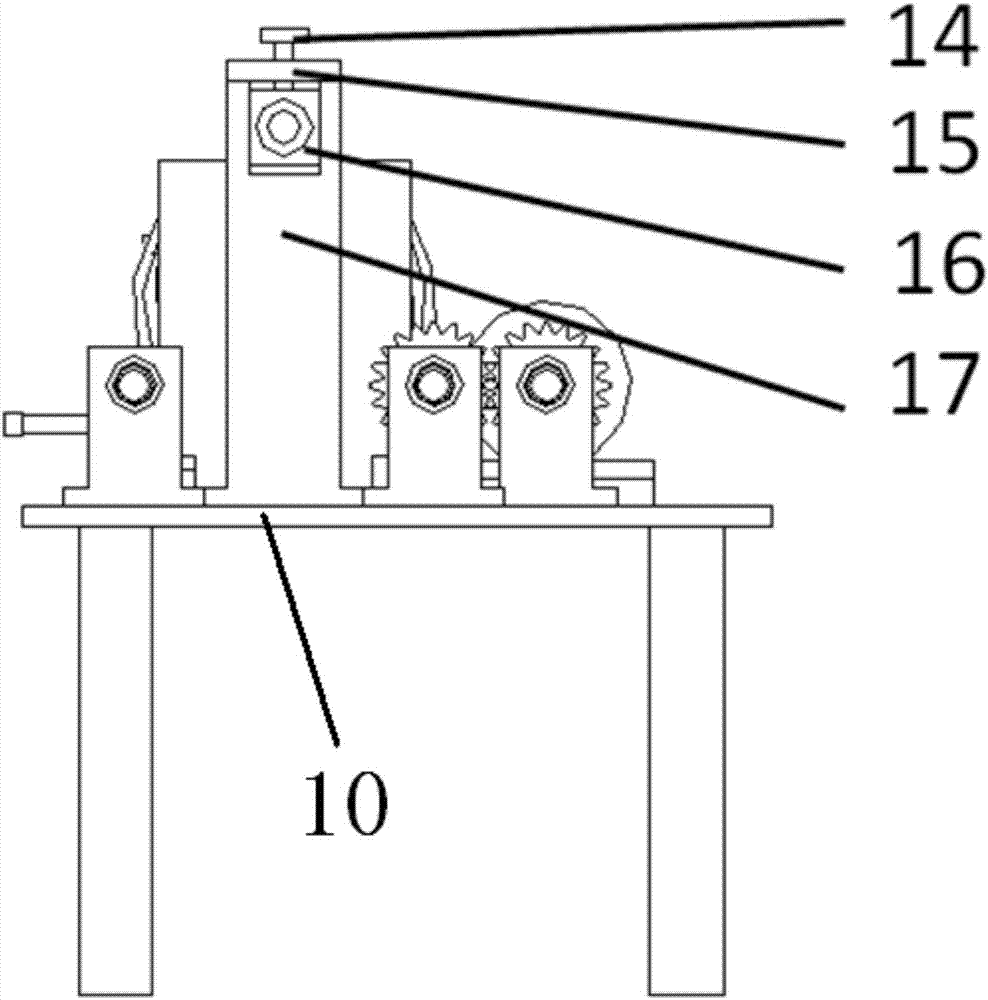

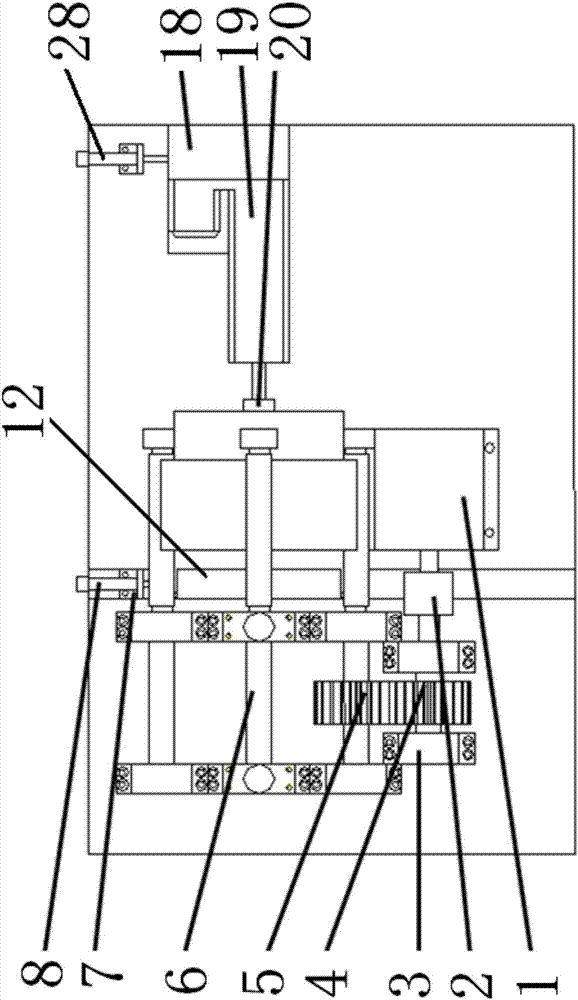

[0020] An oil and gas well casing wear test bench, comprising:

[0021] The simulated sleeve rotation drive assembly can fix the position of the simulated sleeve 11 and drive the simulated sleeve 11 to rotate;

[0022] The simulated tension loading component can apply axial tensile stress to the simulated drill pipe 25;

[0023] The drill pipe clamp 12 can fix the position of the simulated drill pipe 25;

[0024] When the oil and gas well casing wear test bench was in the experimental state, the simulated casing 11 was sleeved outside the simulated drill pipe 25, the inner diameter of the simulated casing 11 was greater than the outer diameter of the simulated drill pipe 25, and the axis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com