Porous plate etalon for multi-sensor measurement system and combined error detection method

A multi-sensor, measurement system technology, applied in the field of standard devices, can solve the problem that the standard device cannot be used for sensor error detection at the same time, and achieve the effect of simple layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

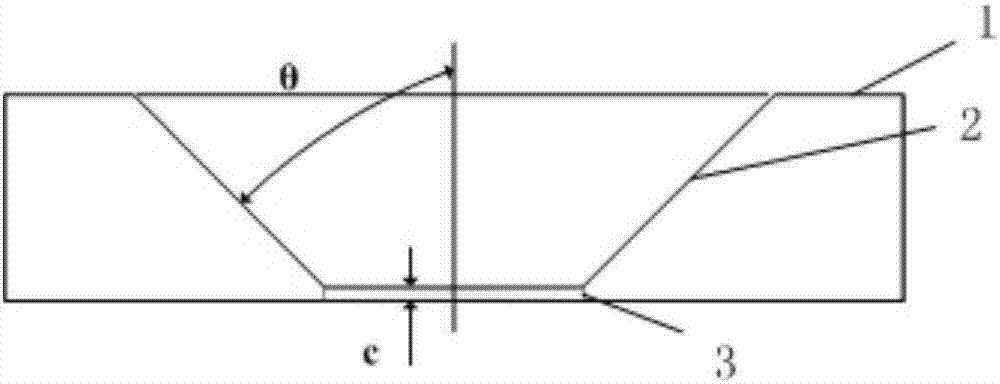

specific Embodiment approach 1

[0047] A multi-well plate standard for use in multi-sensor measurement systems such as figure 1 As shown, it includes a flat plate body 1, and the plate body 1 is provided with A-type longitudinal measuring holes and B-type transverse measuring holes distributed according to their respective linear topological structures; the A-type longitudinal measuring holes and B-type transverse measuring holes The measuring holes are all composed of conical holes 2 and circular holes 3 on the same axis, the large end of the conical hole 2 is located on the upper surface of the plate body 1, and its small end communicates with the circular hole 3 located on the lower surface of the plate body 1, The diameter of the small end of the tapered hole 2 is equal to the diameter of the circular hole 3; the diameter d of the circular hole 3 is 10mm≤d≤51mm, the height c of the circular hole 3≤0.3mm, and the roundness of the circular hole 3 less than 1 μm; the cone angle θ of the tapered hole 2 is 30...

specific Embodiment approach 2

[0053] The difference between the porous plate standard of this specific embodiment and specific embodiment 1 is:

[0054] In this specific embodiment, the extension distance L 1 and extension distance L 2 Both are 60mm; the cone angle θ of the cone hole is 45°, and the diameter of the circular hole is 12mm; the plate body is made of high-speed steel or ceramic material, and the flatness of the plate body is lower than 2 μm. In this way, the standard can be adapted to a multi-sensor measurement system with a large measurement range and high precision; the standard made of high-speed steel or ceramic material has good dimensional stability and is not easy to deform; the flatness of the strip is less than 2 μm , can improve the precision of the standard itself, thereby improving the sampling precision and reducing the error between the measured value and the actual value.

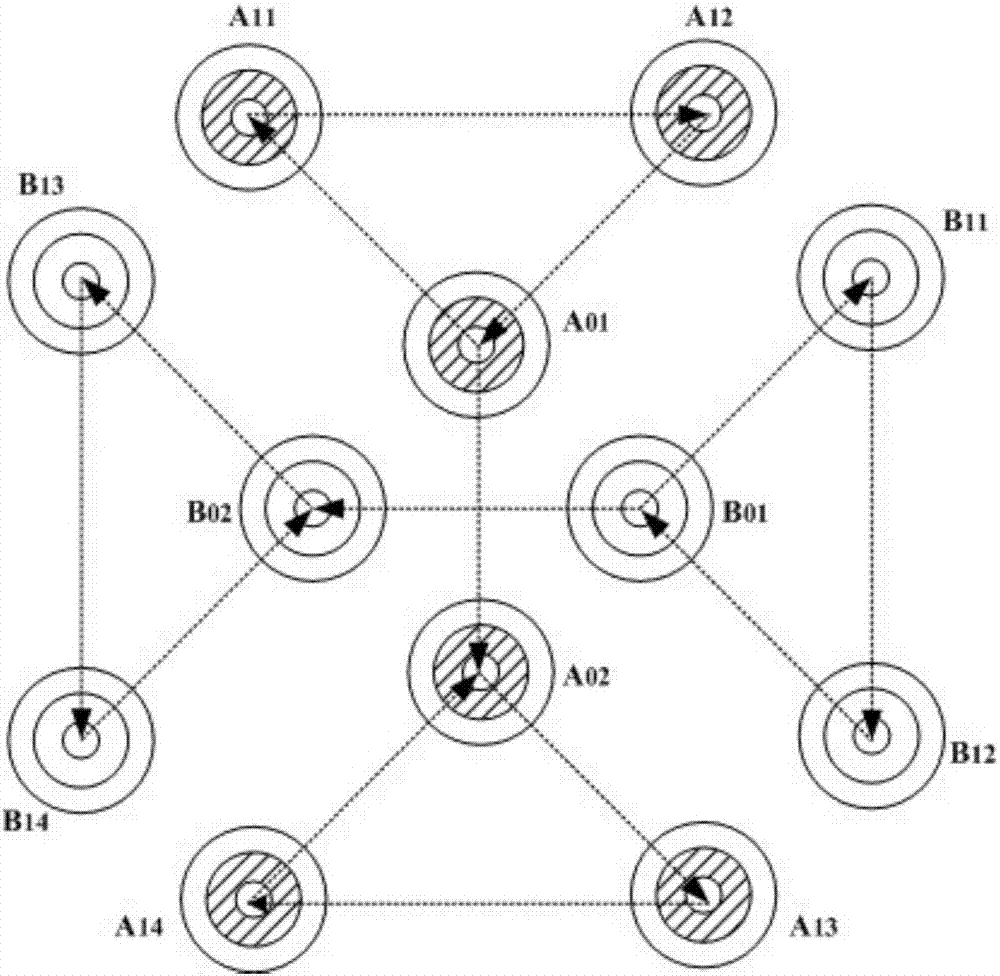

[0055] In this specific embodiment, if figure 2 As shown, there are a total of 12 measurement holes on...

specific Embodiment approach 3

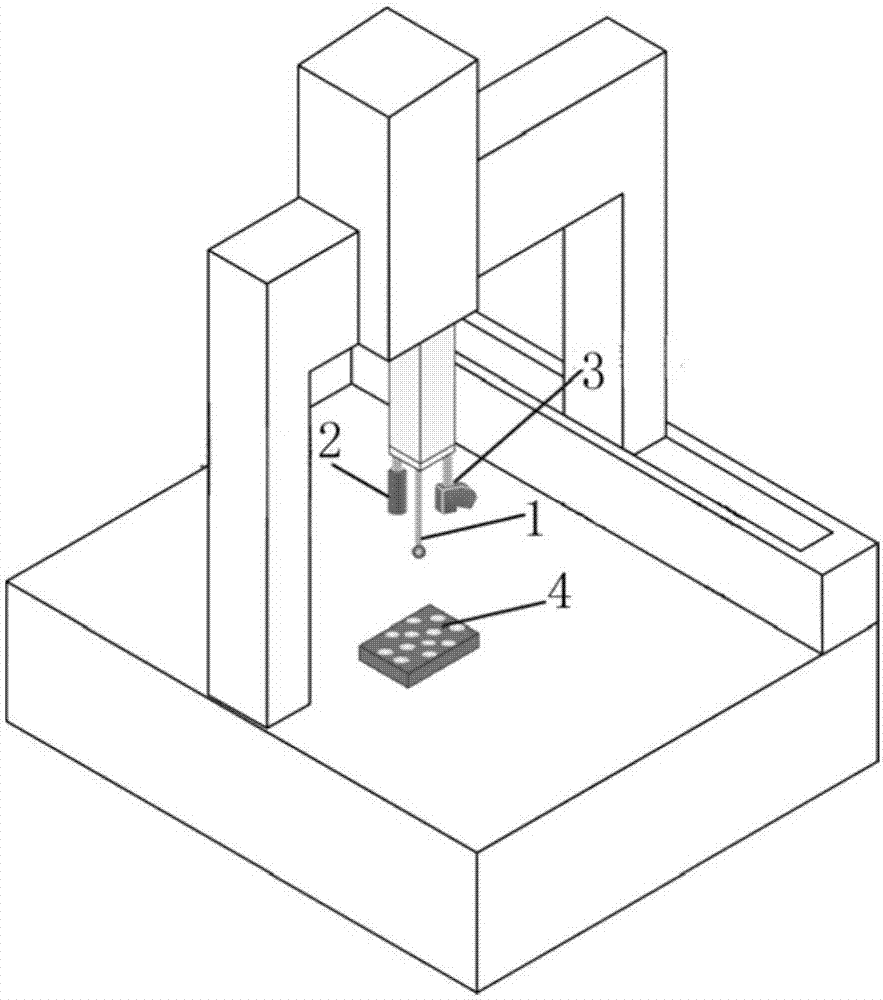

[0057] This specific embodiment samples the porous plate standard device in the specific embodiment 2 to carry out error detection to the multi-sensor measurement system, such as Figure 2 to Figure 4 shown.

[0058] A joint error detection method using the porous plate standard of the present invention, the multi-sensor measurement system has n types of sensors for size measurement, and at least includes any one of a contact sensor, an image sensor or a laser sensor, The multi-sensor of this specific embodiment has 3 kinds of sensors: 3 kinds of sensors of contact sensor 1, image sensor 2 and laser sensor, comprise the following steps:

[0059]Step 1: Number all measurement wells on the multiwell plate standard:

[0060] Number the longitudinal measurement holes of category A: number the first-level category A node located at the upper end of the same vertical line as A01, and the first-level category A node at the lower end as A02, and the two left and right level two categ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Extension distance | aaaaa | aaaaa |

| Extension distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com