Multi-point oil injection pump

An oil injection pump, multi-point technology, applied in the direction of lubricating pumps, lubricating oil control valves, bearing components, etc., can solve problems such as uneven mixing of oil and gas, insufficient lubrication, excessive lubrication, etc., to improve oil injection efficiency and oil injection stability , The effect of reducing the cost of oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings, but it should be noted that these embodiments do not limit the present invention. Equivalent transformations or substitutions all fall within the protection scope of the present invention.

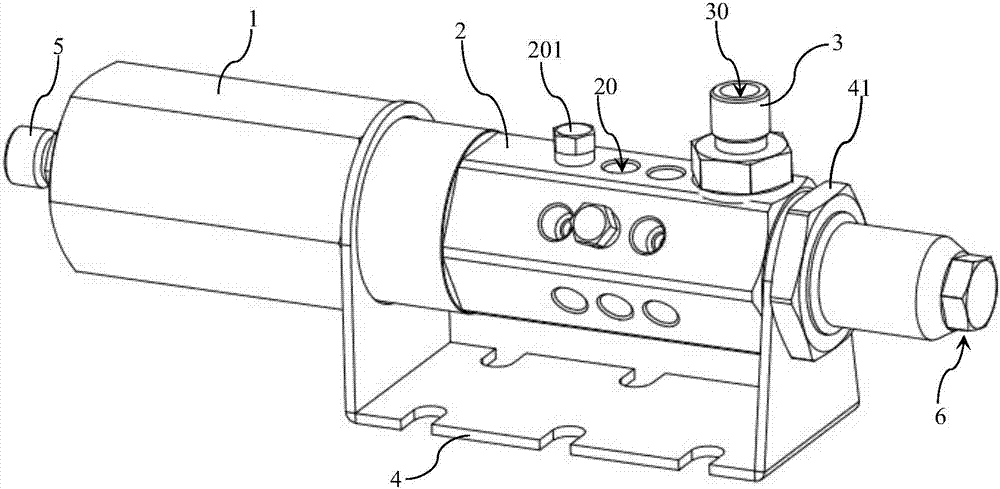

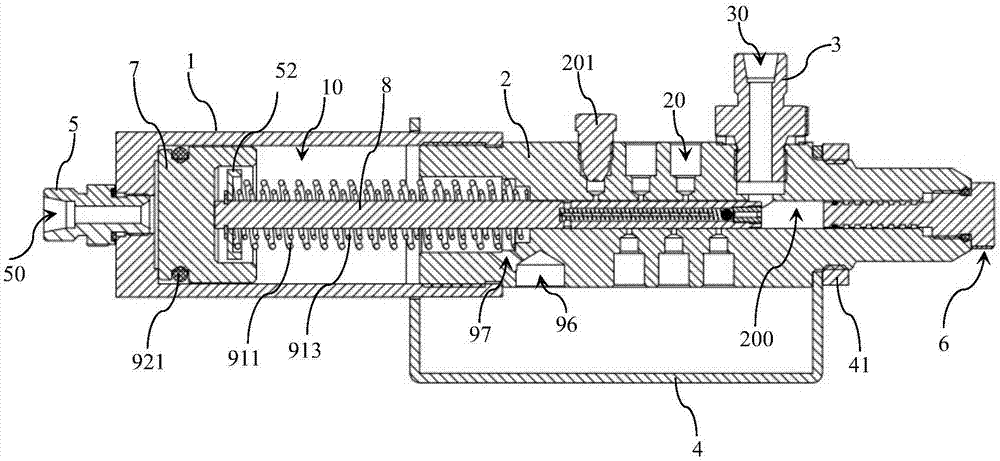

[0022] like Figure 1-4 A multi-point oil injection pump is shown, which is mainly used in the flue gas treatment system of the waste incineration power plant, and stably delivers lubricating oil to the oil-air lubrication device of the high-speed motor in the system, so that the oil and gas can be constant, stable and uniform Mix well to ensure the normal operation of the oil-air lubrication device.

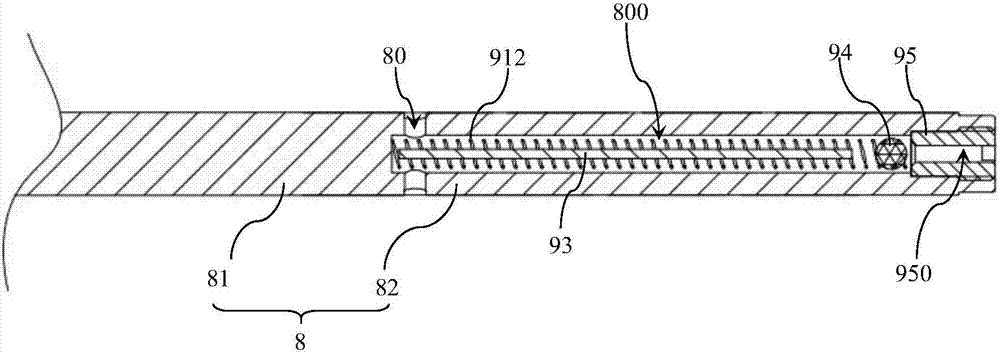

[0023] The multi-point oil injection pump includes a valve body 2 provided with a spool passage 200, a spool 8 partially housed in the spool passage 200, an oil inlet joint 3 communicating with the spool passage 200, and a plugging spool passage 200 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com