Advance timbering device of dig-anchor-integrated comprehensive mining machine

A technology of advanced support and fully mechanized excavator, applied in the direction of support device, slitting machine, mine roof support, etc., can solve the problems of large life safety of on-site operators, limited support area, affecting the operator's sight, etc., and saves money. The effect of manpower and time, shortened preparation time, fast and accurate process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

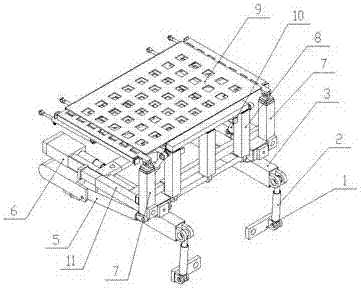

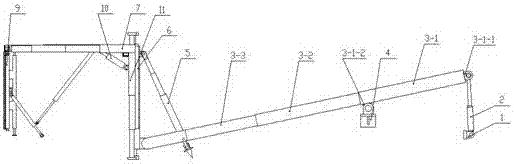

[0071] Such as figure 1 and figure 2 As shown, the technical solution adopted in the present invention comprises 2 telescopic beams 3, 2 telescopic beam swing oil cylinders 2 are hinged on the 2 telescopic beams 3, and a swing folding bracket 6 and a swing folding bracket 6 are installed at the front end of the telescopic beam 3. The bracket flips the oil cylinder 5, and the combined middle telescopic support beam 8 is installed on the swing folding bracket 6, and the support oil cylinder 10 of the combined middle telescopic support beam 8 is installed between the swing folding bracket 6 and the combined middle telescopic support beam 8, External telescopic support beams 7 are installed on both sides of the combined telescopic support beam 8 in the middle, and an outer support cylinder 11 is installed on the external telescopic support beam 7 in a directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com