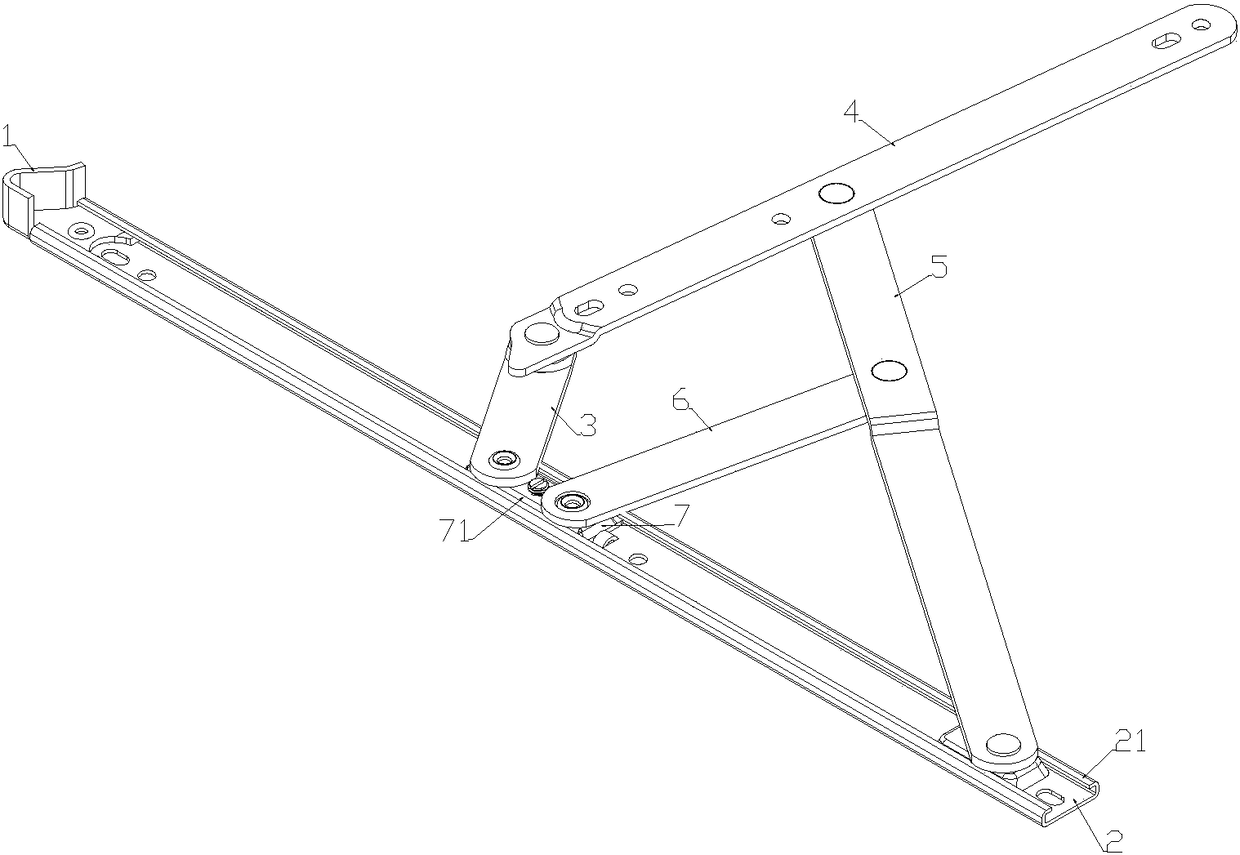

A sliding block of a sliding stay hinge for a window and the sliding stay hinge

A technology of sliding stay hinges and sliders, which is applied to the fastening devices of wing leaves, building fastening devices, buildings, etc., which can solve the problem of increasing the pressure of sliding stay hinges, keeping the width of sliding rails from being too wide, and increasing the stress of sliding stay hinges. Problems such as force, to achieve the effect of prolonging the service life, smooth opening and closing operation, and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following further describes the present invention with reference to the drawings and specific embodiments to help understand the content of the present invention.

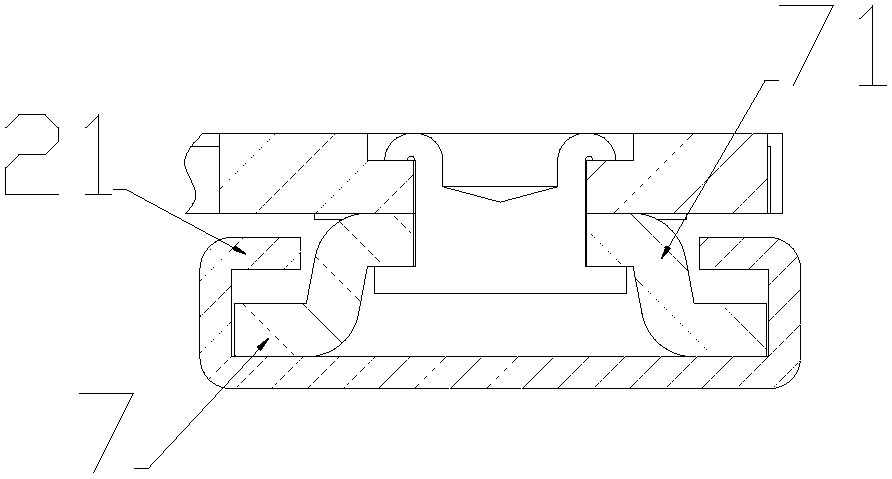

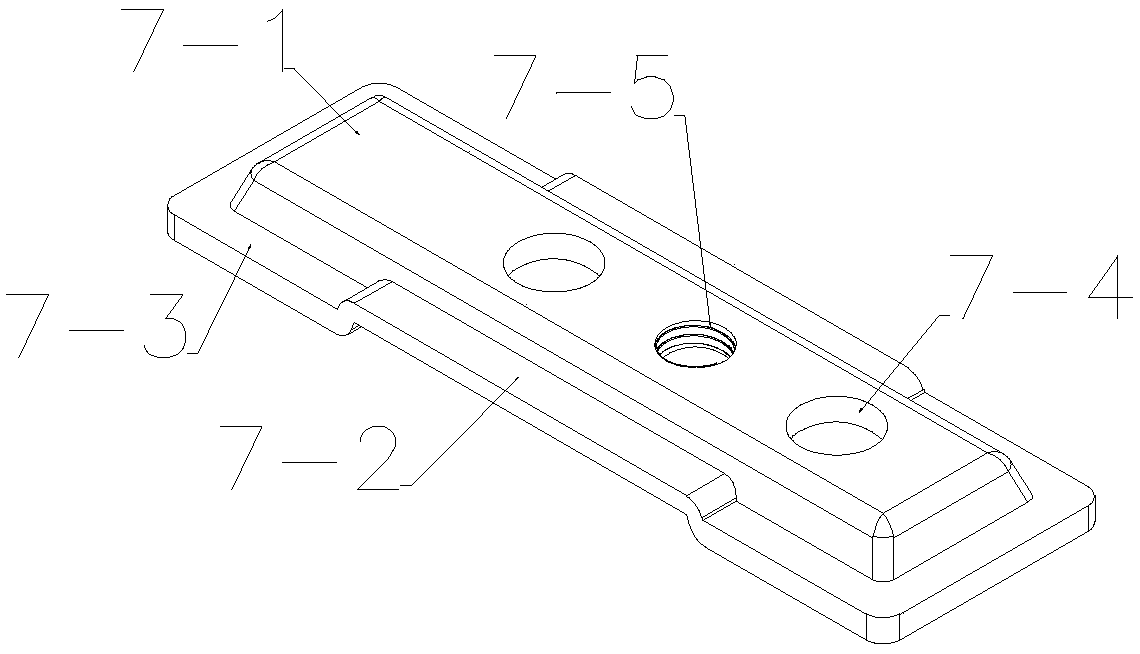

[0037] Such as Figure 2a-2b As shown, a slider is stamped from a 1.5-2mm thick copper plate; the middle of the slider 7 block is stamped with an upward protrusion 7-1, and the protrusion 7-1 is left with the edge of the slider 7. There is a distance, and the protrusion 7-1 is similar to a rectangular table or other ellipsoidal shapes. This shape has good stability and is beneficial to strengthen the load-bearing capacity of the slider 7; the two longer sides 7-3 of the slider 7 The middle section is punched into an upwardly convex middle part 7-2, so that the two sides 7-3 form a stepped shape with a convex middle and low sides. The height of the middle part 7-2 is slightly smaller than that of the slide rail to be installed. The height of the inner space from the upper flange 2-1 to the bottom of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com