Construction method of reinforced concrete corrugated plate pile underground structure

A technology of reinforced concrete and corrugated sheet piles, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as T-shaped through-slot blocking, sheet piles that cannot be used normally, and I-beams that cannot be inserted smoothly , to achieve the effect of maintaining integrity and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

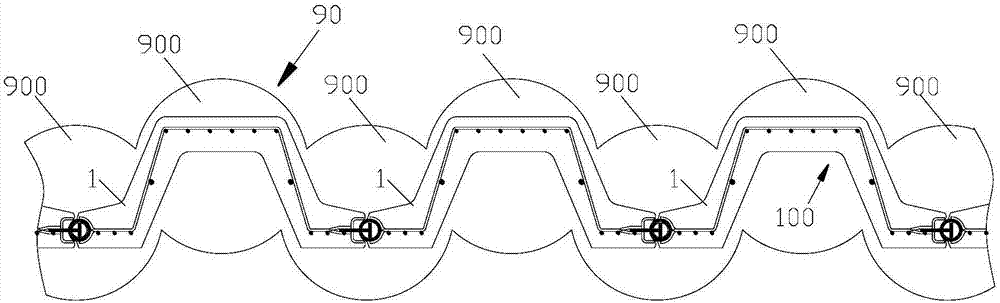

[0064] refer to figure 1 and figure 2 , in this embodiment, reinforced concrete corrugated sheet piles are used to build an underground structure, which is composed of interconnected reinforced concrete corrugated sheet piles. Specifically, a continuous underground groove 90 is excavated underground first, and then reinforced concrete corrugated sheet piles 1 It is formed by sinking into continuous underground grooves and interlocking reinforced concrete corrugated sheet piles 1 , wherein the continuous underground grooves 90 are formed by circular guide holes 900 overlapping each other in the horizontal direction. In this embodiment, a zigzag folded line 950 is formed by sequentially connecting the centers of the leading holes, and an included angle β exists between adjacent line segments on the folded line 950 .

[0065]The specific construction method is carried out in the following steps:

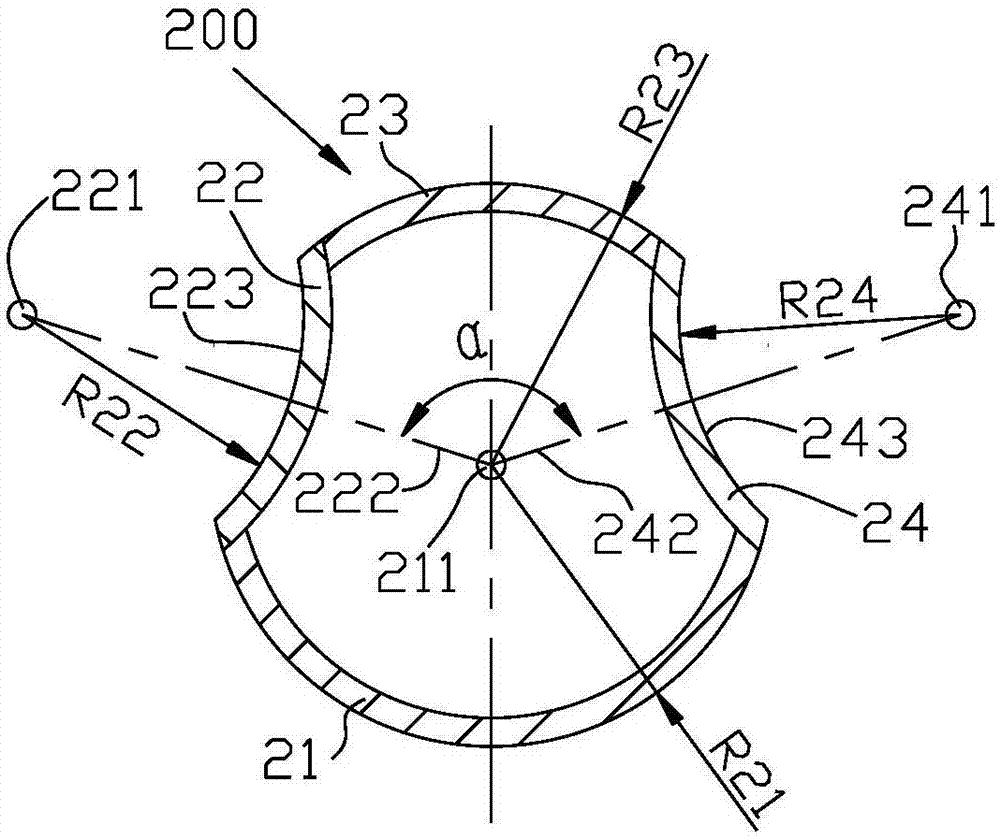

[0066] (1) Prepare special-shaped steel casing 200 and reinforced concrete corru...

Embodiment 2

[0091] This embodiment is an improvement on the basis of Embodiment 1, please refer to Figure 15 The difference between this embodiment and Embodiment 1 is that a female joint part 44 is disposed on the first flange part 42, and the female joint part 44 includes an outer surface 443, a locking through hole 441, and penetrates and cuts off the outer surface. 443 of the gap 442, the gap 442 communicates with the through hole 441; the female joint part 44 is covered with a concrete protection layer 49, and the concrete protection layer 49 has a convex portion protruding outward along the width direction of the reinforced concrete sheet pile. The convex part has an arc-shaped outer surface 492; the concrete protection layer 49 has an opening 491 corresponding to and communicating with the notch 442 of the female joint part 44, and the width of the opening 491 is not smaller than the width of the notch 442 of the female joint part. In this embodiment, the width of the opening 491 ...

Embodiment 3

[0094] This embodiment is an improvement on the basis of implementation 1 or 2, please refer to Figure 16 and Figure 17 , the width of the gap 17 of the female joint part is greater than the thickness of the connecting plate 151 of the male joint part; fenders 16 are arranged on the front and rear sides of the connecting plate, when two reinforced concrete corrugated sheet piles are connected to each other, The fender 16 of one of the reinforced concrete corrugated sheet piles is located in the through hole of the female joint part 14 of the other reinforced concrete corrugated sheet pile. Under the promotion of external force, the fender can block the connecting plate and the female The gap between the gaps of the joint portion; the inner surface of the snap-through hole is arc-shaped, and the snap-through hole in this embodiment is filled with concrete 18, and under the push of the concrete 18, the fender 16 will The gap between the connection plate 151 and the gap is sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com