Door-shaped assembled reinforced concrete box culvert and construction method thereof

A reinforced concrete and construction method technology, applied in the direction of buildings and road bottom layers, can solve the problems of narrow application range, poor integrity, and many blocks, and achieve the effect of wide applicability, less blocks, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

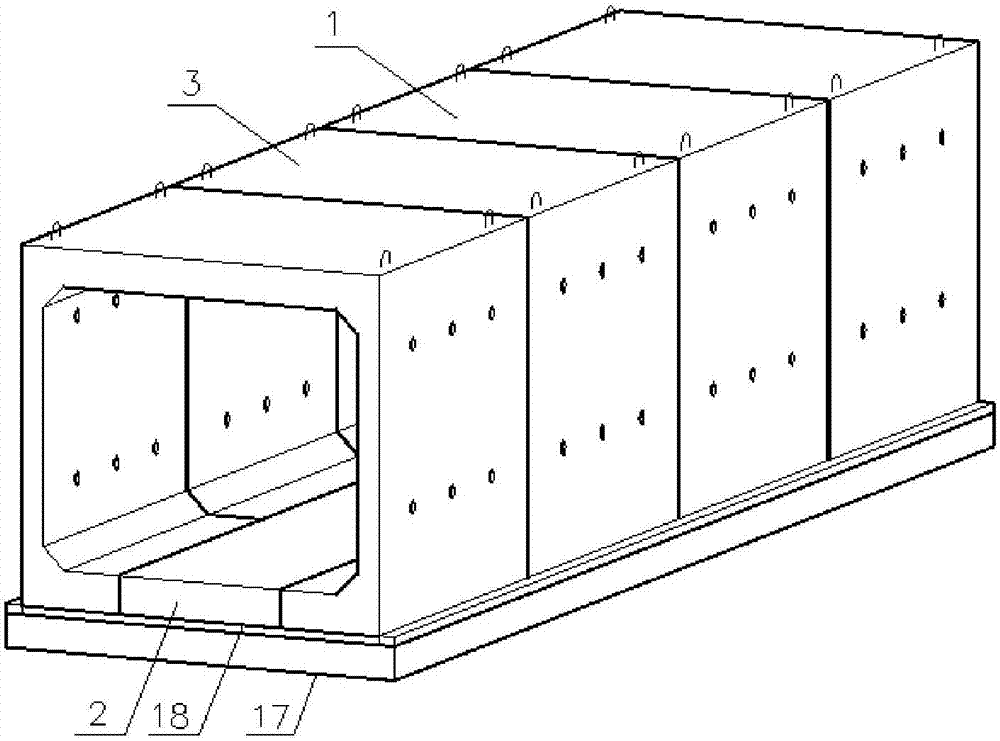

[0028] see figure 1 , the door-shaped assembled reinforced concrete box-shaped culvert of the preferred embodiment of the present invention comprises a prefabricated door-shaped reinforced concrete culvert 1 and a cast-in-place reinforced concrete floor 2, and the prefabricated door-shaped reinforced concrete culvert 1 is composed of several prefabricated door-shaped reinforced concrete components 3 assembled along the axial direction.

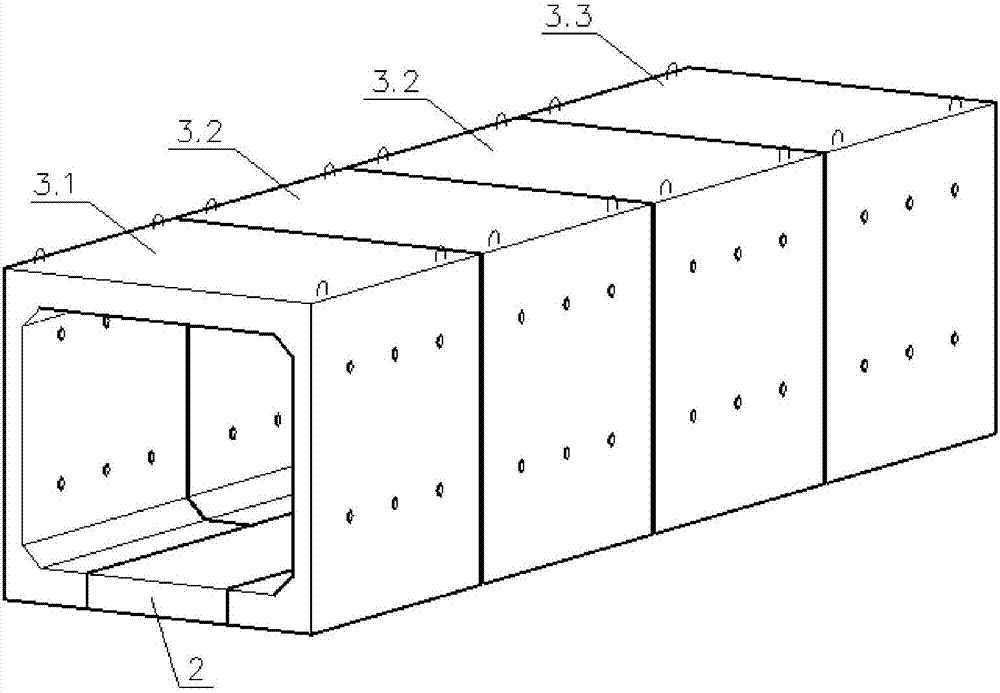

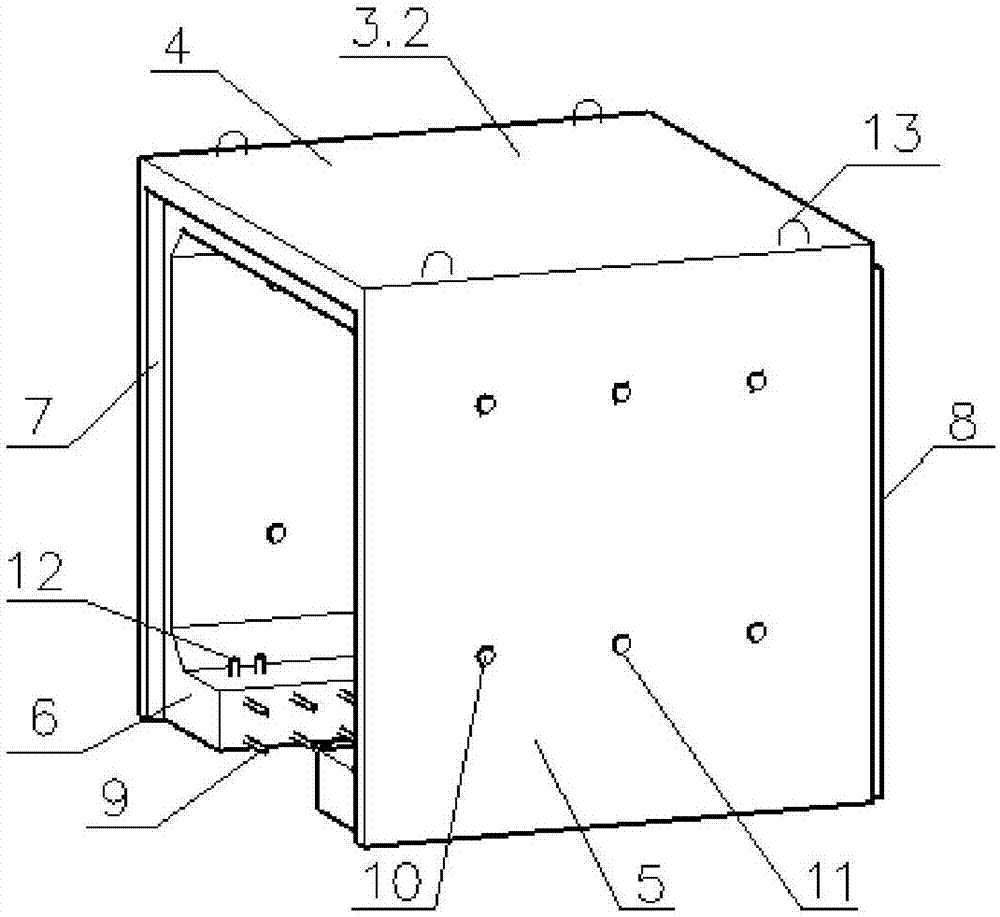

[0029] Please refer to figure 2 , the prefabricated door-shaped reinforced concrete member 3 has slightly different structures according to different positions, and can be divided into prefabricated door-shaped member front section 3.1, prefabricated door-shaped member middle section 3.2 and prefabricated door-shaped member rear section 3.3. The front section 3.1 of the prefabricated portal-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com