Environment-friendly biomass plastic material preparation method and application thereof

A biomass plastic and environment-friendly technology, applied in the field of plastic materials, can solve the problems of large usage of plastic materials, obvious environmental impact, and large volume of waste, and achieve the effects of strong practicability, easy availability of raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

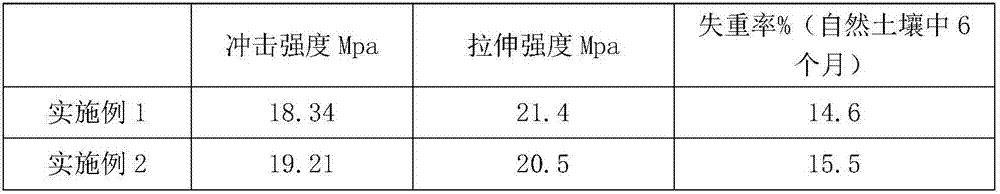

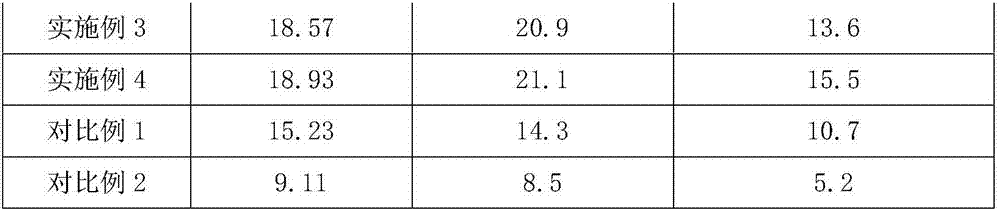

Examples

Embodiment 1

[0028] (1) Wash and dry 5 parts of wheat straw, 6 parts of corn stalk, 5 parts of rice husk, 4 parts of pine bark, 3 parts of peat, and 3 parts of peanut shell, and add them together to a crushing and cutting machine for cutting;

[0029] (2) adding the biomass shear product of step (1) into a high-temperature and high-pressure steam reactor for heat treatment, the reaction temperature is 450° C., the pressure is 5 MPa, and the reaction time is 20 minutes;

[0030] (3) adding the biomass mixed fragments of step (2) into a high-speed ball mill for ball milling, the ball milling time is 30 minutes, the ball milling power is 350W, a small amount of liquid nitrogen is added during the ball milling, the product is pulverized thoroughly, the ball milling product is collected and sieved, The sieve aperture is 80 mesh;

[0031] (4) adding the biomass powder obtained in step (3) to 75% benzoyl solution for activation treatment, the treatment time is 60min;

[0032] (5) Mix 10 parts of...

Embodiment 2

[0038] (1) Wash and dry 7 parts of wheat straw, 7 parts of corn stalk, 6 parts of rice husk, 5 parts of pine bark, 4 parts of peat, and 4 parts of peanut shell, and add them together to a crushing and cutting machine for cutting;

[0039] (2) adding the biomass shear product of step (1) into a high temperature and high pressure steam reactor for heat treatment, the reaction temperature is 470°C, the pressure is 7MPa, and the reaction time is 30min;

[0040] (3) adding the mixed biomass fragments of step (2) into a high-speed ball mill for ball milling, the ball milling time is 40 minutes, the ball milling power is 350W, a small amount of liquid nitrogen is added during the ball milling, the product is pulverized thoroughly, and the ball milling product is collected and sieved, The sieve aperture is 80 mesh;

[0041] (4) adding the biomass powder obtained in step (3) to 75% benzoyl solution for activation treatment, the treatment time is 60min;

[0042] (5) Mix 15 parts of pol...

Embodiment 3

[0048] (1) Wash and dry 9 parts of wheat straw, 8 parts of corn stalk, 7 parts of rice husk, 8 parts of pine bark, 7 parts of peat, and 4 parts of peanut shell, and add them together to a crushing and cutting machine for cutting;

[0049] (2) adding the biomass shear product of step (1) into a high-temperature and high-pressure steam reactor for heat treatment, the reaction temperature is 480° C., the pressure is 8 MPa, and the reaction time is 32 minutes;

[0050] (3) adding the biomass mixed fragments of step (2) into a high-speed ball mill for ball milling, the ball milling time is 50 minutes, the ball milling power is 350W, a small amount of liquid nitrogen is added during the ball milling, the product is pulverized thoroughly, and the ball milling product is collected and sieved, The sieve aperture is 80 mesh;

[0051] (4) adding the biomass powder obtained in step (3) to 75% benzoyl solution for activation treatment, the treatment time is 60min;

[0052] (5) Mix 20 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com