Self-curing polycarboxylic type water reducer and preparation method thereof

A technology of protecting polycarboxylic acid and water reducing agent, which is applied in the field of concrete additives, can solve problems such as self-curing functional polycarboxylic acid not involved, and achieve the effects of good comprehensive performance, reduced operating strength and guaranteed quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

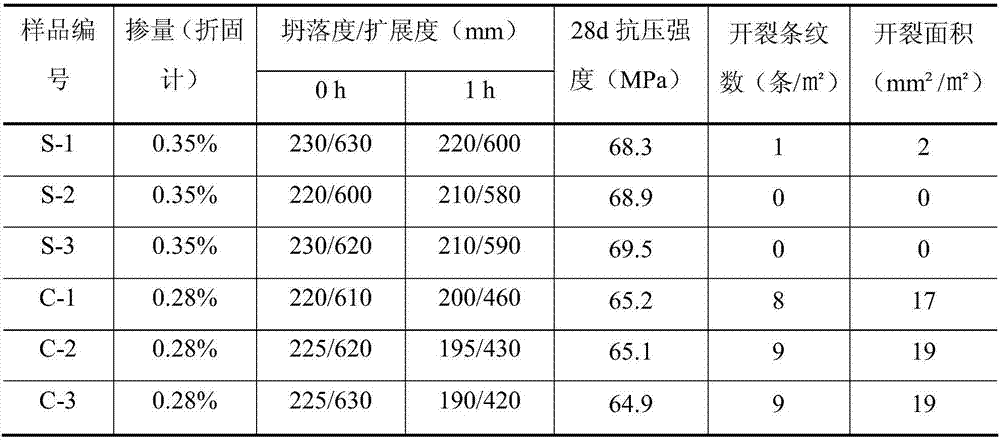

Examples

Embodiment 1

[0036] The molecular weight of TPEG is 1200, and the molar ratio of macromonomer TPEG: small monomer ACAM and AA: regulating monomer BMZ: grafting monomer QYN: crosslinking agent RJZ is 1:3.5:0.2:0.1:0.05, of which ACAM:AA The molar ratio is 1:5, the chain transfer agent is mercaptoacetic acid, and its consumption is 0.1% of the total mass of polyether macromonomer, small monomer, adjustment monomer and graft monomer, and the initiator is potassium persulfate, and its consumption It is 0.5% of the total mass of polyether macromonomer, small monomer, regulating monomer and grafting monomer, and is prepared as a 3.0% aqueous solution.

[0037] Add QYN to the reaction bottle, and add deionized water to make a bottom solution with a concentration of 5%, turn on the stirring, and raise the temperature to 60°C. TPEG plus deionized water is made into 50% solution A, AA, ACAM, BMZ, RJZ, chain transfer agent and deionized water are made into 30% solution B, and initiator potassium pers...

Embodiment 2

[0039]The molecular weight of HPEG is 2400, the molar ratio of macromonomer HPEG: small monomer ACAM and AA: regulating monomer BMZ: grafting monomer QYN: crosslinking agent RJZ is 1:5:0.3:0.1:0.08, of which ACAM:AA The molar ratio is 1:4, the chain transfer agent is mercaptoacetic acid, and its consumption is 0.5% of the total mass of polyether macromonomer, small monomer, adjustment monomer and graft monomer, and the initiator is potassium persulfate, and its consumption It is 0.6% of the total mass of polyether macromonomer, small monomer, regulating monomer and grafting monomer, and is prepared as a 3.0% aqueous solution.

[0040] Add QYN to the reaction bottle, and add deionized water to make a bottom solution with a concentration of 6%, turn on the stirring, and raise the temperature to 70°C. Add TPEG and deionized water to make 30% solution A, AA, ACAM, BMZ, RJZ, chain transfer agent and deionized water to make 30% solution B and initiator potassium persulfate solution ...

Embodiment 3

[0042] The molecular weight of HPEG is 3000, the molar ratio of macromonomer HPEG: small monomer ACAM and AA: regulating monomer BMZ: grafting monomer QYN: crosslinking agent RJZ is 1:4:0.4:0.1:0.1, of which ACAM:AA The molar ratio is 1:4, the chain transfer agent is mercaptopropionic acid, and its consumption is 0.2% of the total mass of polyether macromonomer, small monomer, adjustment monomer and graft monomer, and the initiator is ammonium persulfate. The dosage is 1.0% of the total mass of polyether macromonomer, small monomer, regulating monomer and grafting monomer, and it is formulated into a 5.0% aqueous solution.

[0043] Add QYN to the reaction bottle, and add deionized water to make a bottom solution with a concentration of 7%, turn on the stirring, and raise the temperature to 60°C. Add TPEG and deionized water to make 40% solution A, AA, ACAM, BMZ, RJZ, chain transfer agent and deionized water to make 35% solution B and initiator ammonium persulfate solution C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com