Road damage detection robot system

A robot system and damage detection technology, applied in manipulators, manufacturing tools, etc., can solve problems such as inability to evaluate road conditions, high labor intensity, and inability to automatically evaluate data from independent detection, so as to reduce the impact of road traffic, economy and Improve security and realize the effect of long-term dynamic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

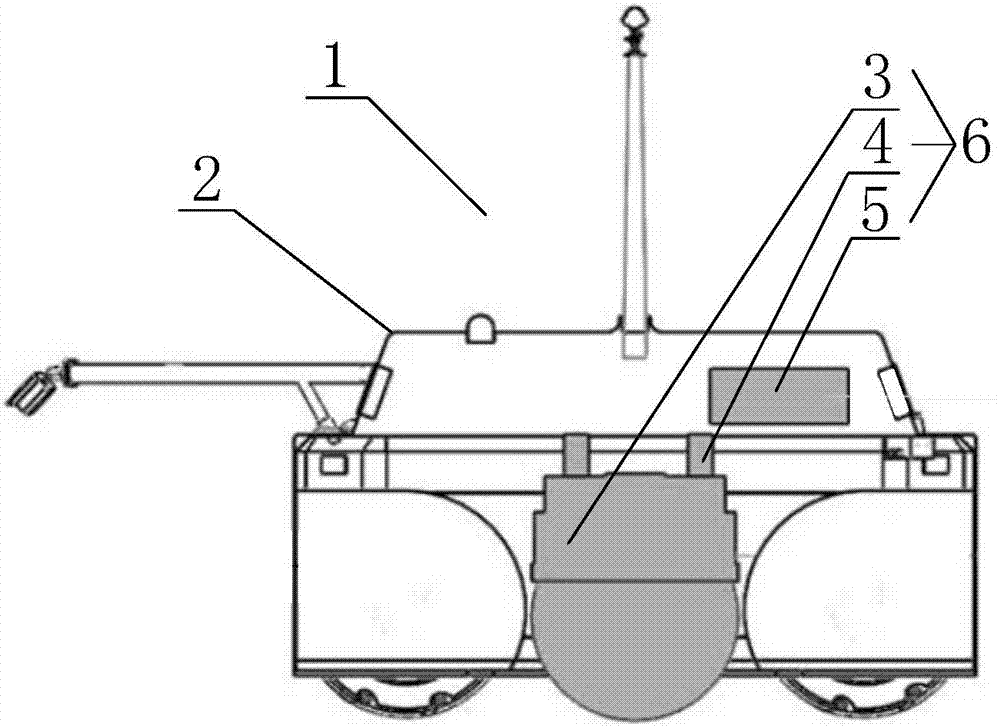

[0034] Embodiment 1 of the present invention: as figure 1 As shown, a road damage detection robot system includes a robot body system 1, and the robot body system 1 includes a mobile platform system 2 and a detection system 6, and the detection system 6 is installed on the mobile platform system 2; The scanning detector 3, the lifting mechanism 4 and the detector control system 5, the lifting mechanism 4 is installed on the mobile platform system 2, the percussion scanning detector 3 is installed on the lifting mechanism 4, the detector control system 5 and the percussion scanning detector 3 electrical connections.

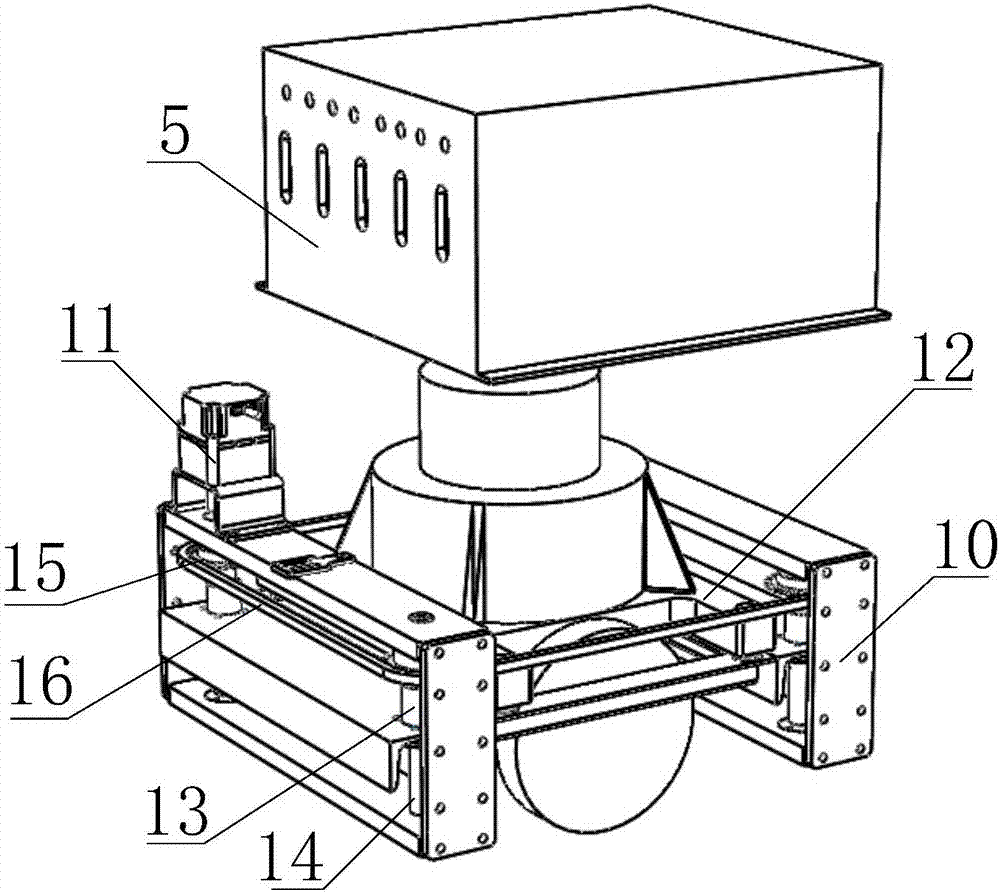

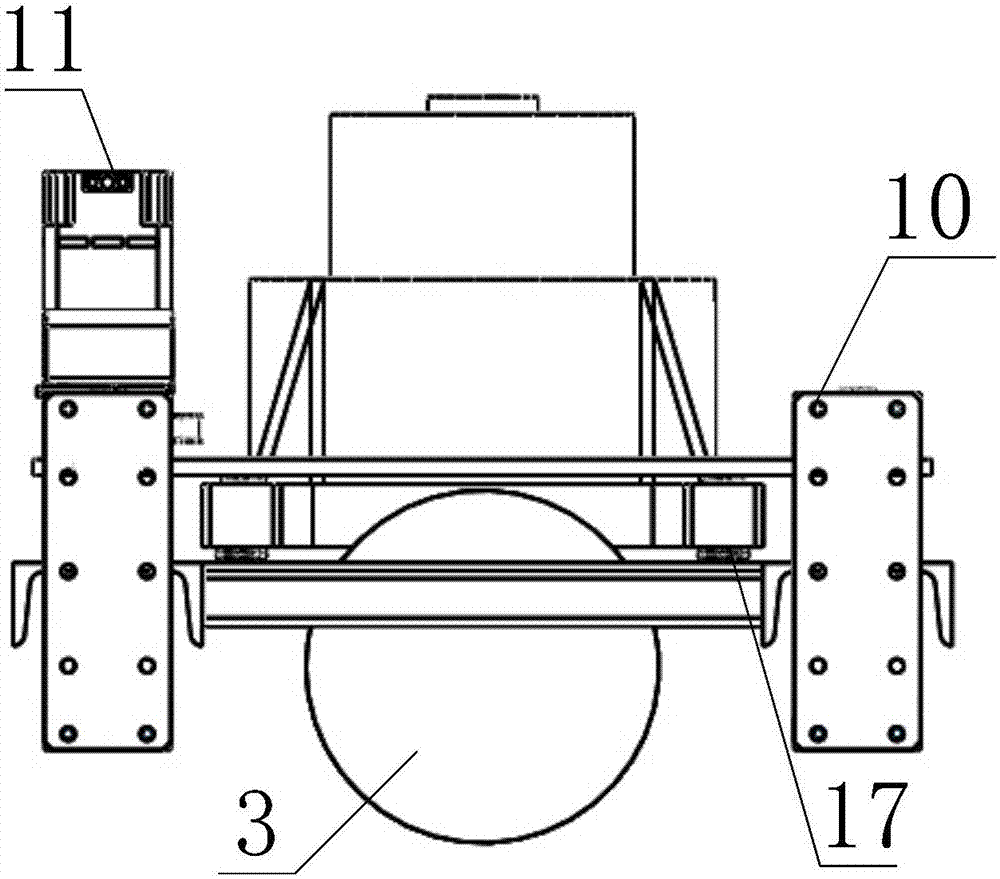

[0035] Such as figure 2 As shown, the lifting mechanism 4 includes a support frame 10 installed on the mobile platform system 2, a drive motor 11 and a carrying platform 12 are installed on the support frame 10, the output shaft of the drive motor 11 is connected with the carrying platform 12, and the knock scanning detection The instrument 3 is installed on th...

Embodiment 2

[0038] Embodiment 2: as figure 1 As shown, a road damage detection robot system includes a robot body system 1, and the robot body system 1 includes a mobile platform system 2 and a detection system 6, and the detection system 6 is installed on the mobile platform system 2; The scanning detector 3, the lifting mechanism 4 and the detector control system 5, the lifting mechanism 4 is installed on the mobile platform system 2, the percussion scanning detector 3 is installed on the lifting mechanism 4, the detector control system 5 and the percussion scanning detector 3 electrical connections.

[0039] Such as figure 2 As shown, the lifting mechanism 4 includes a support frame 10 installed on the mobile platform system 2, a drive motor 11 and a carrying platform 12 are installed on the support frame 10, the output shaft of the drive motor 11 is connected with the carrying platform 12, and the knock scanning detection The instrument 3 is installed on the carrying platform 12 . ...

Embodiment 3

[0041] Embodiment 3: as figure 1 As shown, a road damage detection robot system includes a robot body system 1, and the robot body system 1 includes a mobile platform system 2 and a detection system 6, and the detection system 6 is installed on the mobile platform system 2; The scanning detector 3, the lifting mechanism 4 and the detector control system 5, the lifting mechanism 4 is installed on the mobile platform system 2, the percussion scanning detector 3 is installed on the lifting mechanism 4, the detector control system 5 and the percussion scanning detector 3 electrical connections.

[0042] The output end of the driving motor 11 is connected with a lead screw 14, and the carrying platform 12 is provided with a threaded hole, and the lead screw 14 matches the threaded hole. The system also includes a remote control system 18, the remote control system 18 is wirelessly connected to the robot body system 1, and the mobile platform system 2 is equipped with two sets of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com