Hub-type robot and detecting method for system for autonomously detecting road surfaces

A robot system and hub-type technology, applied in signal transmission systems, instruments, measuring devices, etc., can solve problems such as high labor intensity, low efficiency, and affecting traffic efficiency, so as to improve economy and safety, and improve overall system performance , Improve the effect of detection security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

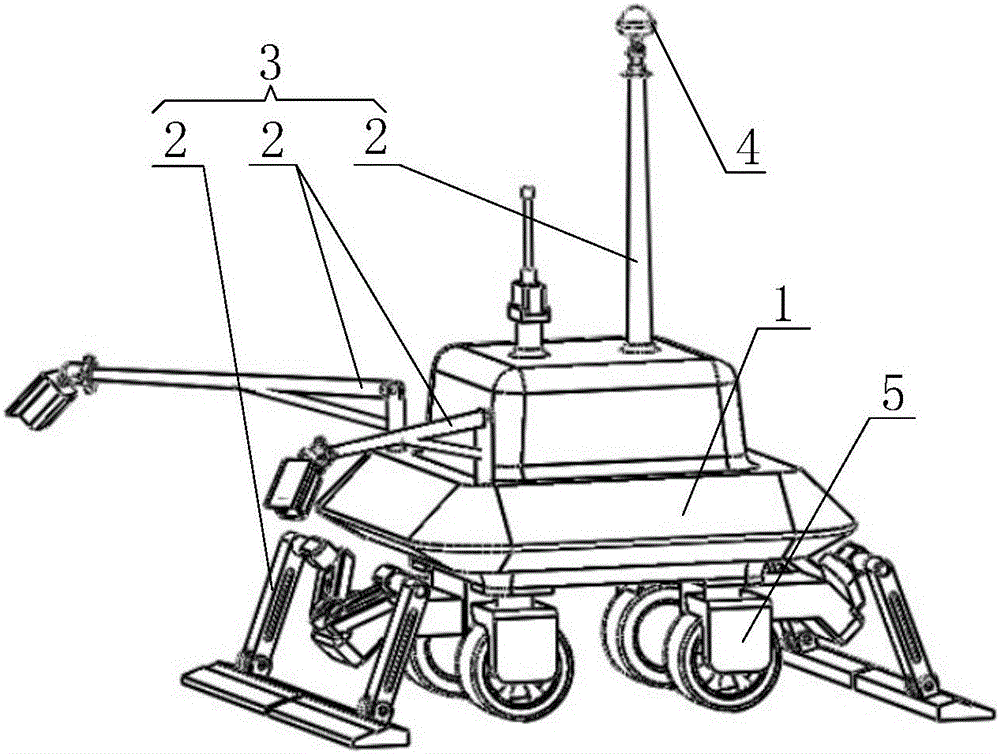

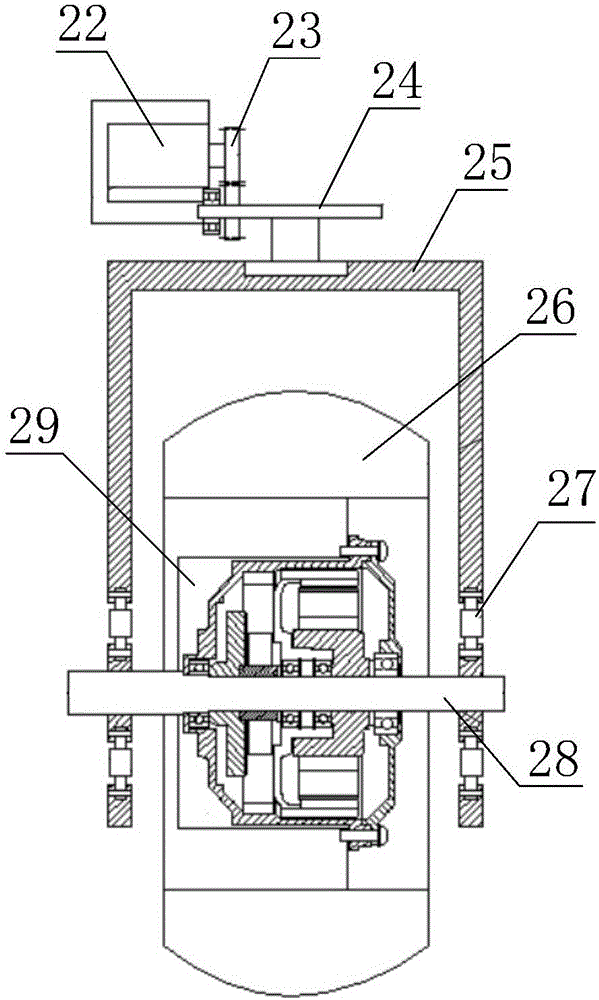

[0045] Embodiment 1 of the present invention: as figure 1 , Figure 4 and Figure 10 As shown, a hub-type road surface autonomous detection robot system includes a robot body 1 and a remote monitoring auxiliary system 21. The robot body 1 is provided with a control system 20, a non-destructive testing system 19 and an operating mechanism 3. The operating mechanism 3 is installed on the robot On the body 1, the non-destructive testing system 19 is connected to the operating mechanism 3, the control system 20 is electrically connected to the operating mechanism 3, and the control system 20 is electrically connected to the non-destructive testing system 19; the non-destructive testing system 19 includes a resistivity meter 9, and the operating mechanism 3 includes a telescopic Mechanism 2, resistivity meter 9 is connected with described telescopic mechanism 2, and the bottom of robot body 1 is provided with independent driving steering device 5; Remote monitoring auxiliary syste...

Embodiment 2

[0048] Embodiment 2: as figure 1 , Figure 4 and Figure 10 As shown, a hub-type road surface autonomous detection robot system includes a robot body 1 and a remote monitoring auxiliary system 21. The robot body 1 is provided with a control system 20, a non-destructive testing system 19 and an operating mechanism 3. The operating mechanism 3 is installed on the robot On the body 1, the non-destructive testing system 19 is connected to the operating mechanism 3, the control system 20 is electrically connected to the operating mechanism 3, and the control system 20 is electrically connected to the non-destructive testing system 19; the non-destructive testing system 19 includes a resistivity meter 9, and the operating mechanism 3 includes a telescopic Mechanism 2, resistivity meter 9 is connected with described telescopic mechanism 2, and the bottom of robot body 1 is provided with independent driving steering device 5; Remote monitoring auxiliary system 21 includes control cab...

Embodiment 3

[0050] Embodiment 3: as figure 1 , Figure 4 and Figure 10 As shown, a hub-type road surface autonomous detection robot system includes a robot body 1 and a remote monitoring auxiliary system 21. The robot body 1 is provided with a control system 20, a non-destructive testing system 19 and an operating mechanism 3. The operating mechanism 3 is installed on the robot On the body 1, the non-destructive testing system 19 is connected to the operating mechanism 3, the control system 20 is electrically connected to the operating mechanism 3, and the control system 20 is electrically connected to the non-destructive testing system 19; the non-destructive testing system 19 includes a resistivity meter 9, and the operating mechanism 3 includes a telescopic Mechanism 2, resistivity meter 9 is connected with described telescopic mechanism 2, and the bottom of robot body 1 is provided with independent driving steering device 5; Remote monitoring auxiliary system 21 includes control cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com