Horizontal spiral centrifuge control system

A decanter centrifuge and control system technology, applied in centrifuges and other directions, can solve the problems of equipment data collection lag, equipment failure production accidents, misoperations, etc., and achieve the effects of intuitive monitoring, high degree of automation, and convenient system maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

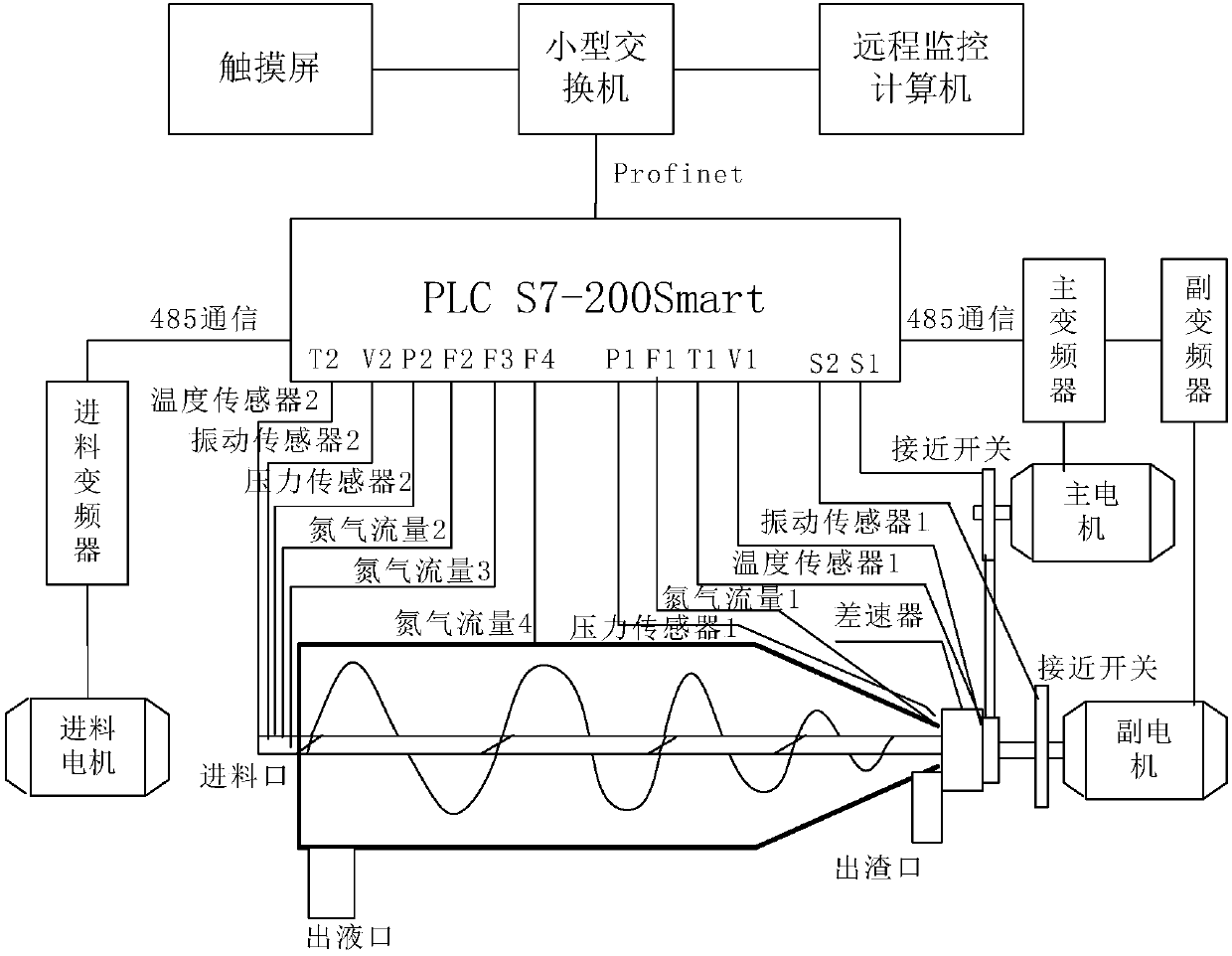

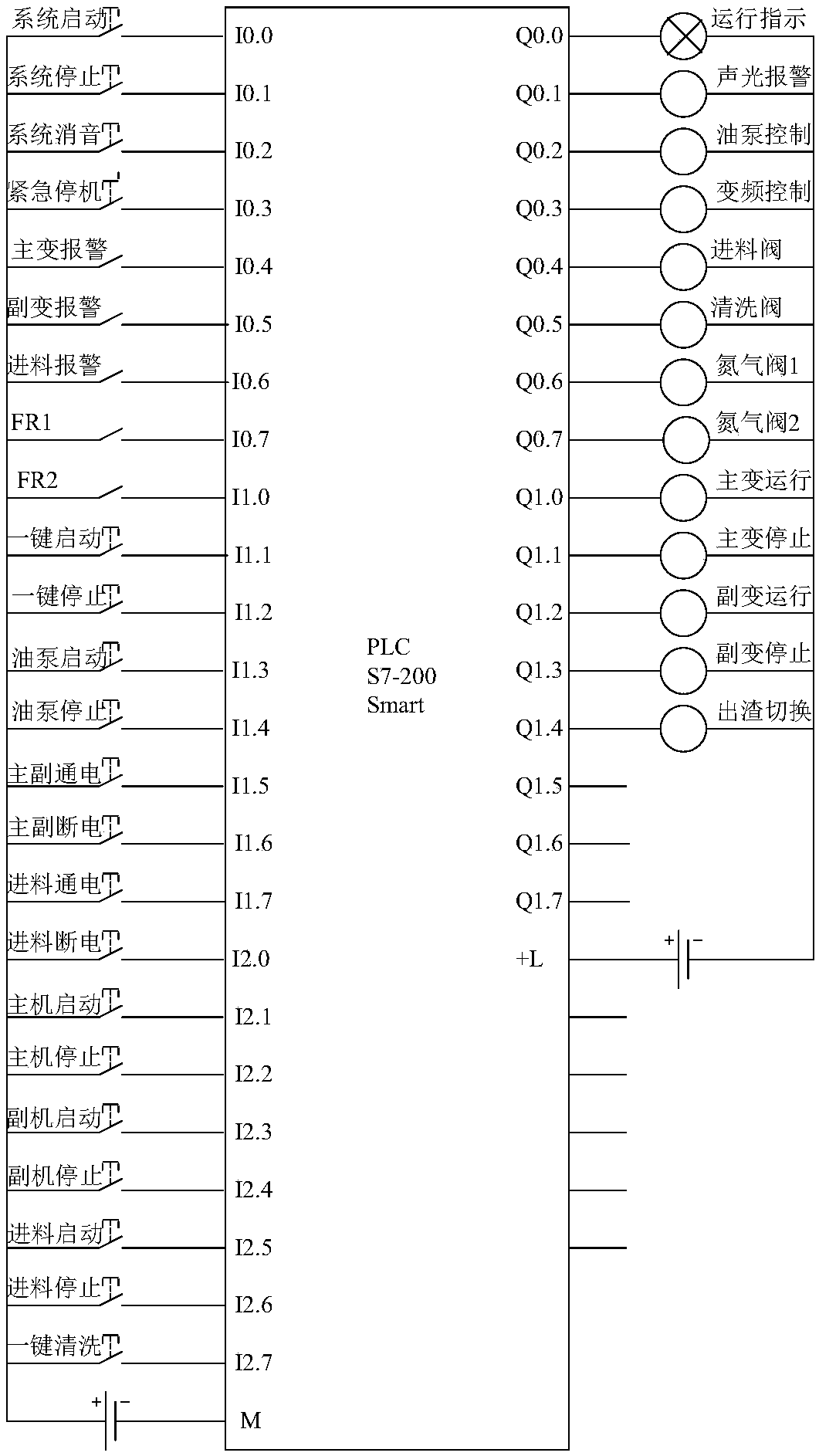

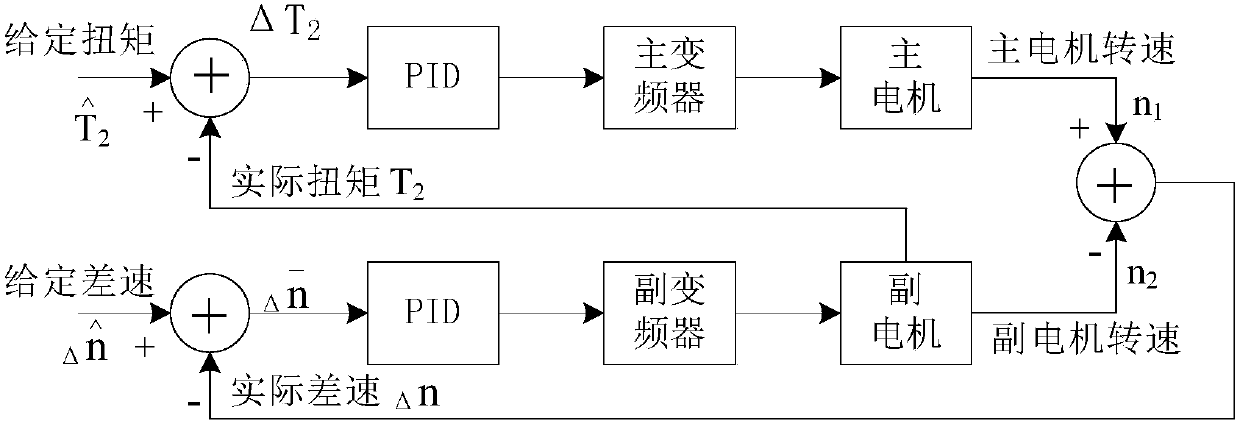

[0021] Example: such as Figure 1-5 As shown, the present invention provides a decanter centrifuge control system, which includes a remote monitoring computer, a small switch connected to the remote monitoring computer, a touch screen connected to the small switch, a programmable controller connected to the small switch, and a The feeding inverter connected to one end of the programming controller, the feeding motor connected to one end of the feeding inverter, the main inverter connected to the other end of the programmable controller, the main motor connected to one end of the main inverter, and the main inverter The other end is connected with a secondary frequency converter, a secondary motor connected with the secondary frequency converter, a plurality of sensors, and a plurality of proximity switches for measuring the rotational speeds of the main and auxiliary motors.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap