Automatic test bench for release bearing of automobile clutch

A technology for separating bearings and clutches, applied in bearing-related force sensors, instruments, measuring devices, etc., can solve the problems of inability to realize full online detection of bearings, unstable test data, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

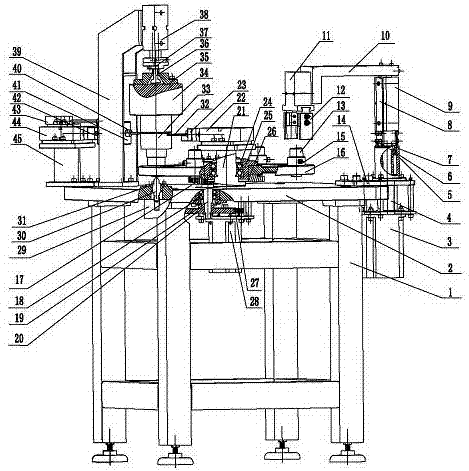

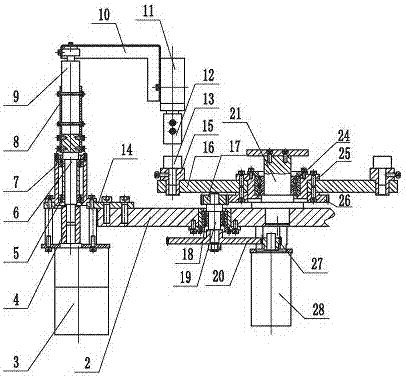

[0025] Such as figure 1 , figure 2 The shown automatic test bench for release bearing of automobile clutch includes a frame 1 welded by square steel, and adjustable anchor bolts are arranged at the back end of the frame 1 . A platform 2 is fixedly connected to the frame 1, and the platform 2 is made of a steel plate.

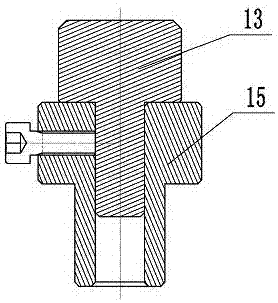

[0026] Vertical shaft 21 is erected fixedly at the central position of platen 2, and the axis line of vertical shaft 21 is perpendicular to the plate surface of platen 2, and vertical shaft bearing 24 that is arranged side by side and is made of two ball bearings is housed on vertical shaft 21, and vertical shaft bearing 24 is fixedly placed in the bearing seat 25 through its outer ring, and the bearing seat 25 is fixedly connected with the turntable 16. This structure makes the turntable 16 rotatably mounted on the vertical shaft 21. A gear shaft 19 is rotatably installed on the platen 2 through a gear shaft bearing 18. The upper and lower ends of the gear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com