Doped gas energy dissipation and gas explosion preventing flood discharging device and flood discharging method thereof

An energy dissipation and gas-proof technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of unstable flow state, non-separation of gas and water, and blockage of gas collection chambers by soil, so as to improve stability and increase The effect of head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

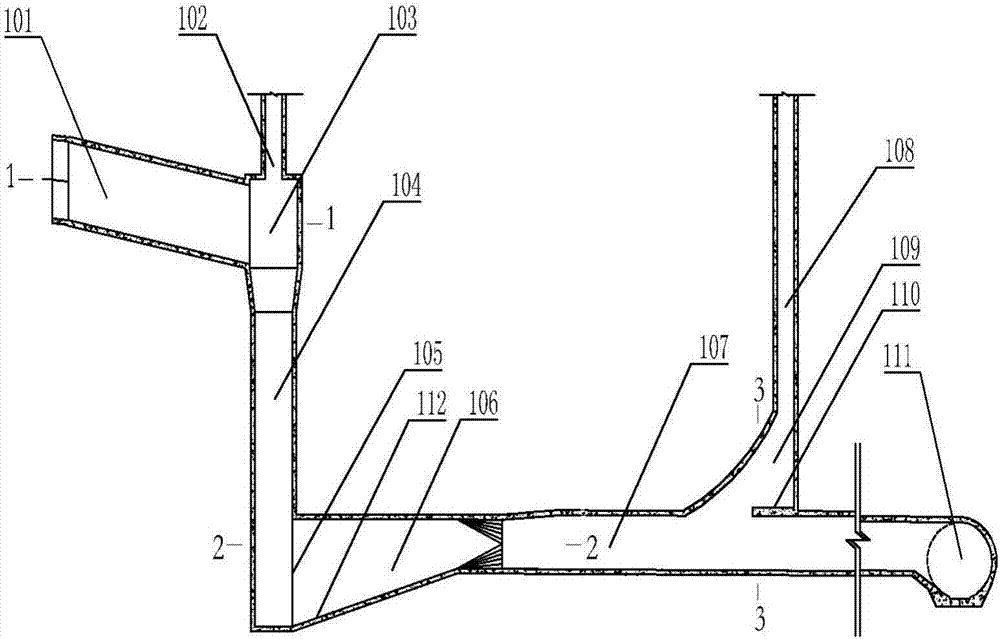

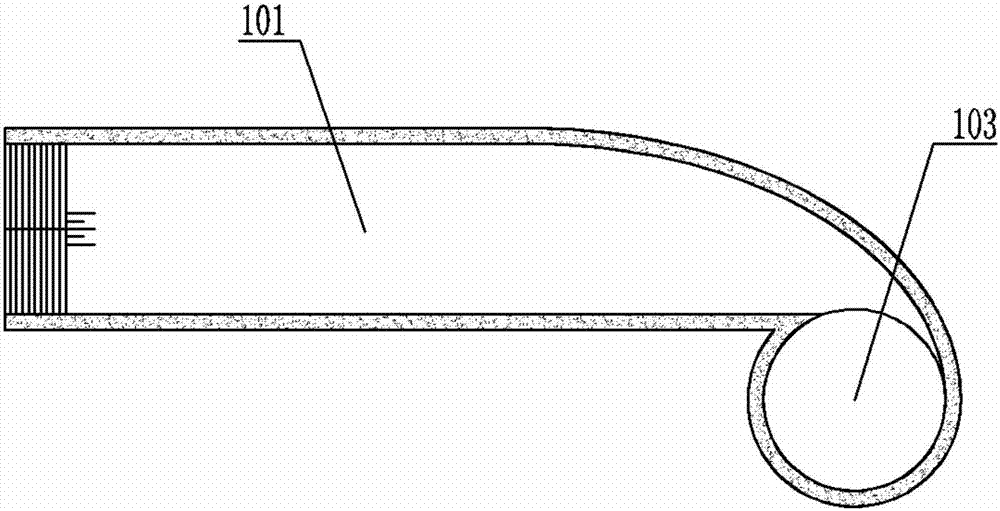

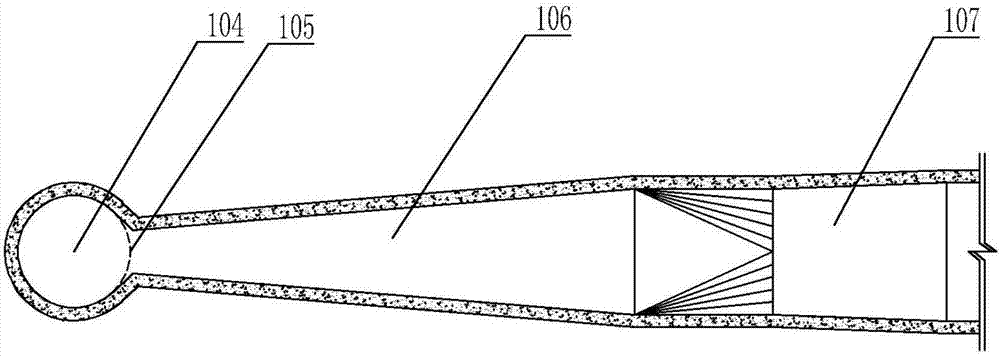

[0028] The present invention provides an aerated energy dissipation and anti-air explosion flood discharge device, as shown in Figure (1-4), which specifically includes a connecting section 101, a vent hole 102, a vortex chamber 103, a shaft 104, a vertical seam 105, an energy dissipation box 106, and a flood discharge branch hole 107, exhaust hole 108), gas collection chamber 109, horizontal plate 110, flood discharge main hole 111; the top of the shaft 104 is connected to the vortex chamber 103, and the top of the vortex chamber 103 is provided with the ventilation hole 102, The side of the vortex chamber 103 is connected to the connecting section 101, the bottom of the shaft 104 is connected to the horizontal energy dissipation box 106, and the joint between the bottom of the shaft 104 and the horizontal energy dissipation box 106 is provided with the The vertical seam 105, the energy dissipation box 106, the flood discharge branch hole 107, and the flood discharge main hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com