Snakelike tube panel lifting device

A lifting device and serpentine tube technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of unsmooth installation process, quality damage of serpentine tube, deformation of serpentine tube, etc., to shorten the assembly period, Increase the scope of use and the effect of adjustable width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

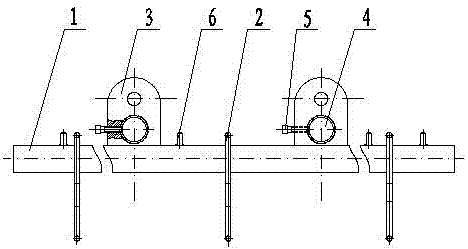

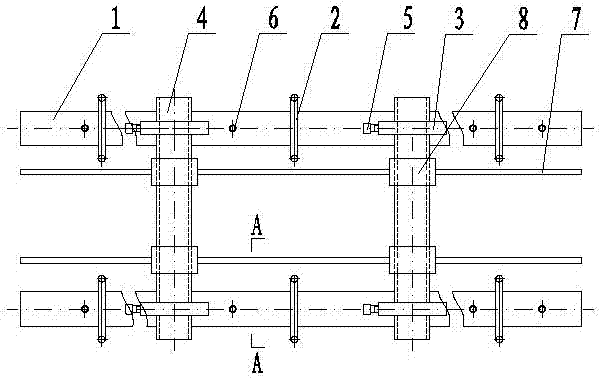

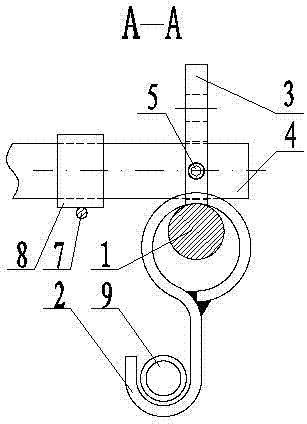

[0020] Such as Figures 1 to 5 As shown, a hoisting device for a serpentine tube panel includes two parallel circular bearing beams 1 with the same length, and a plurality of hooks 2 are sleeved on the circular bearing beams 1, where each circular bearing 13 hooks 2 are set on the beam 1, and at least two lifting lugs 3 are welded on the circular load-bearing beam 1. Here, two lifting lugs 3 are set on each circular load-bearing beam 1, and the lower end of the hook 2 is used for For hooking the elbows 9 at both ends of the serpentine tube panel; a circular beam 4 is arranged between the corresponding lifting lugs 3 on the two circular load-bearing beams 1, and the circular beam 4 passes through the lifting lugs 3 and is detachably connected Together, the detachable connection between them is realized by the positioning screw 5 horizontally arranged on the lifting ear 3. The positioning screw 5 passes through the lifting ear 3 to tighten the circular beam 4 and is perpendicula...

Embodiment 2

[0023] Such as Figures 1 to 5 As shown, on the basis of Example 1, in order to facilitate the unloading of the serpentine tube panel, to ensure that the hook 2 that has been detached from the elbow 9 will not accidentally repeatedly hook the elbow 9, two limit rods 7 are designed. The limit rod 7 is welded to the bottom end of the sleeve 8, and the sleeve 8 is sleeved on the circular beam 4, so that the limit rod 7 can move axially along the circular beam 4, and two sleeves are arranged on each circular beam 4. Tube 8, the same limit rod 7 is welded to the corresponding sleeve 8 bottoms on the two circular beams 4.

[0024] When unloading the serpentine tube panel, each hook 2 is separated from the elbow 9, and the hook 2 is rotated so that it rests on the limit rod 7, and then the device is lifted away from the serpentine tube panel area, so that the setting ensures It is guaranteed that the hook 2 will not be in a shaking state after being separated from the elbow 9, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com