Automatic wire harness winding device

A winding device and wire harness technology, which is applied in the field of wire harnesses, can solve the problems of laborious and laborious, different sizes and shapes of wire coils, and low efficiency of manual winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

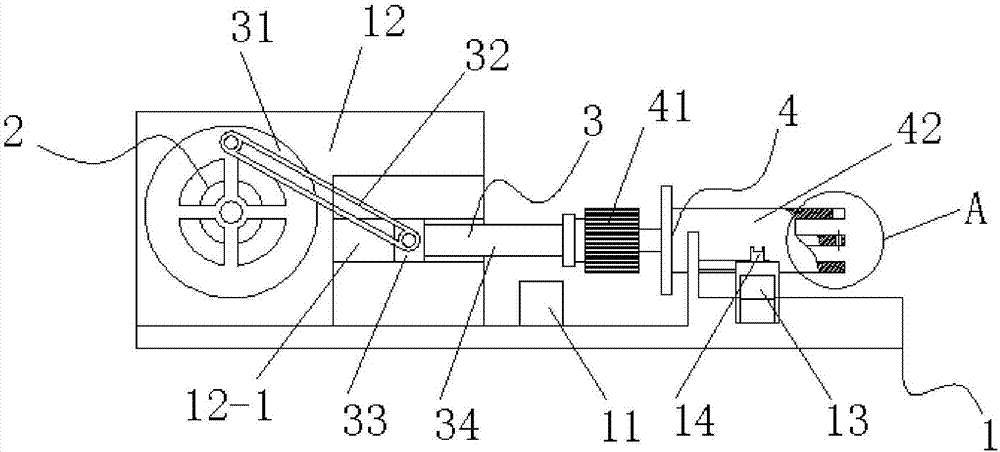

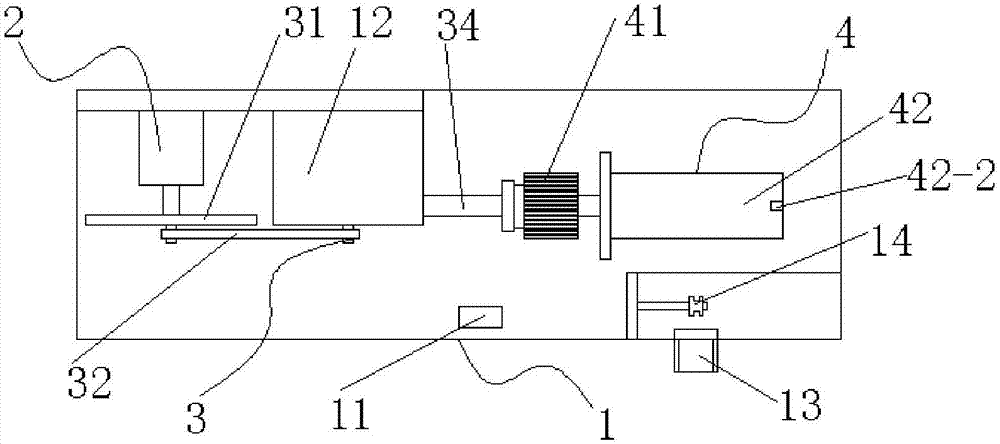

[0015] Such as Figure 1 to Figure 3 Shown is a specific embodiment of the present invention: a wire harness automatic winding device, including a device seat 1, a drive motor 2, a centering slider mechanism 3 and a winding mechanism 4, and the device seat 1 is provided with a controller 11 , vertical wall 12, wiring harness inlet 13 and guide wheel 14, described vertical wall 12 side is provided with chute 12-1, described driving motor 2 is fixedly installed on vertical wall 12 side, described centering slider mechanism 3 is connected with on the one hand The output shaft of the driving motor 2 is fixedly connected, and on the other hand is fixedly connected with the winding mechanism 4 .

[0016] In this embodiment, the centering slider mechanism 3 is composed of a runner 31, a connecting rod 32, a slider 33 and an extension rod 34. The center of the runner 31 is fixedly connected to the output shaft of the driving motor 2, and the connecting One end of the rod 32 is hinged...

Embodiment 1

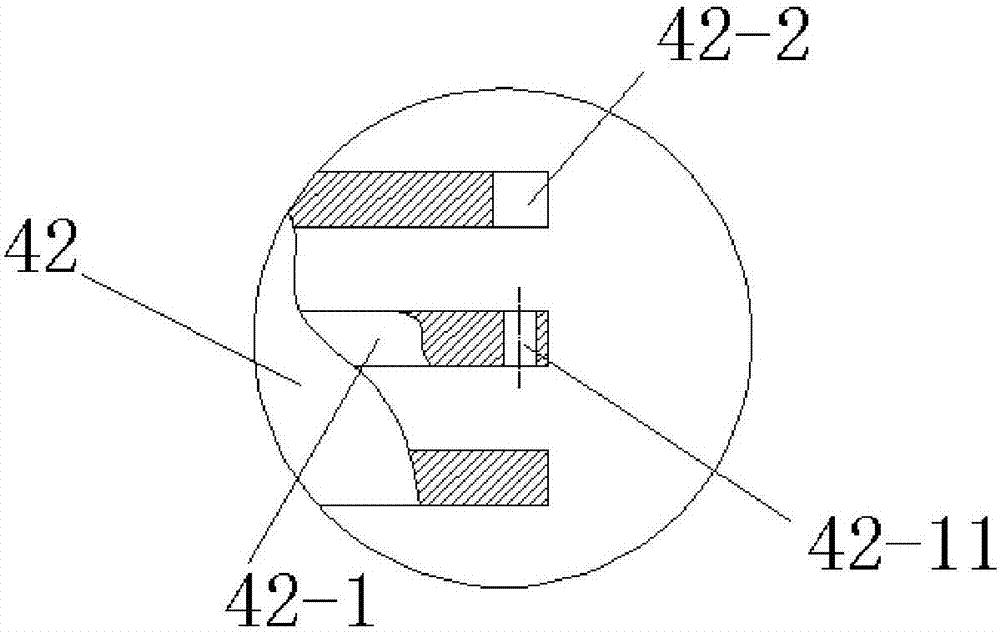

[0021] This invention is a wire harness automatic winding device. When winding the wire harness, the wire harness is now passed through the wire harness inlet 13, bypassed the guide wheel 14, and then the wire harness is passed through the wire harness through the slot 42-2 and then inserted into the wire harness fixing rod. 42-1 fixed in the fixing hole 42-11, and then turn on the drive motor 2 and the rotary motor 41 through the controller 11, the rotary motor 41 drives the wire harness winding drum 42 to rotate, and the drive motor 2 drives the runner 31 to rotate in a circular motion. Rod 32 just carries slide block 33 and does reciprocating linear motion in chute 12-1, because one end of extension rod 34 is fixedly connected with slide block 33, and the other end is fixedly connected with winding mechanism 4, slide block 33 does reciprocating linear motion to drive The winding mechanism 4 performs synchronous reciprocating linear motion, so the wire harness winding drum 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com