Male die lubricating structure based on self-oil-absorption metal and male die lubricating method

A lubricating structure and punch technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of lubricating oil outflow, affecting the working environment, and wasting lubricating oil, etc., and achieve prolonging service life, compact structure, and saving lubrication The effect of oil dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

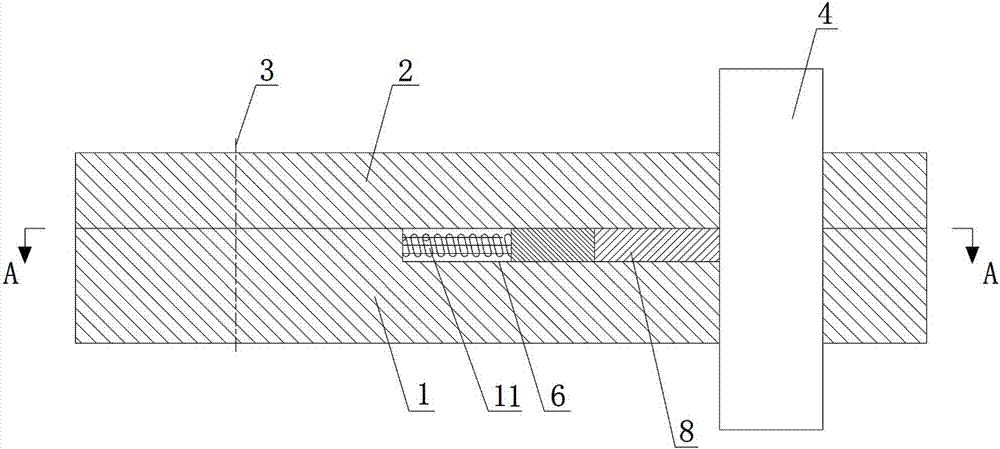

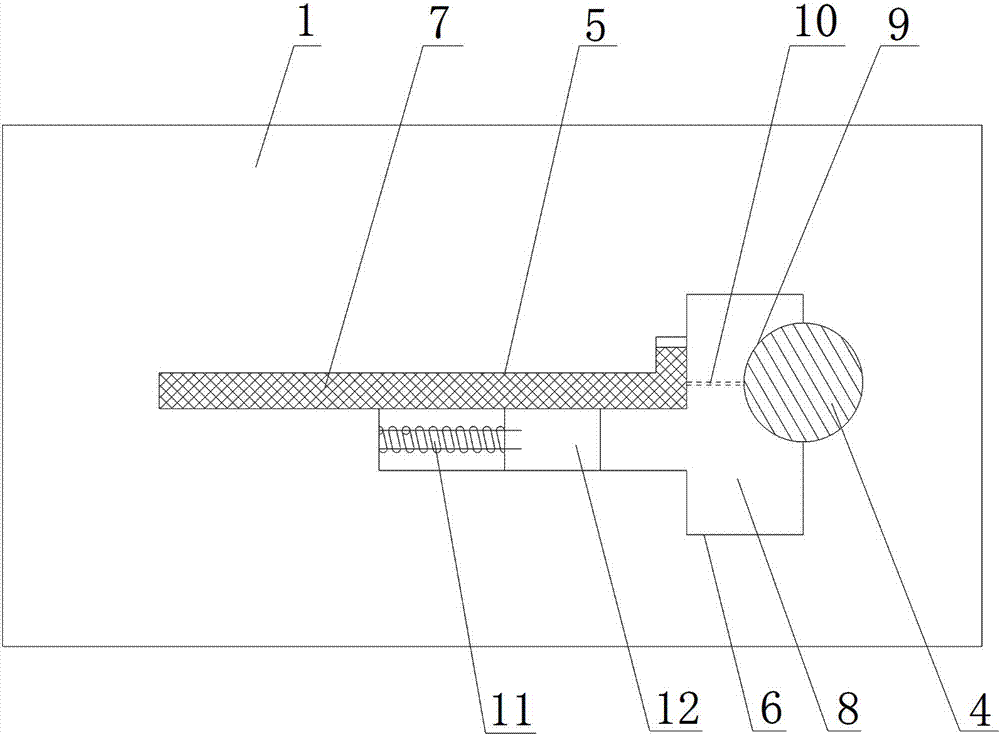

[0022] Such as Figure 1~5 As shown, a punch lubricating structure based on self-absorbing oil metal, it includes a punch 1 and an upper die base 2, a screw 3 is connected between the punch 1 and the upper die base 2, and a screw 3 is connected between the punch 1 and the upper die base 2. A guide column 4 is also installed between them, the top surface of the punch 1 is provided with a strip groove 5 and a T-shaped groove 6, the transverse groove of the T-shaped groove 6 communicates with the strip groove 5, and the strip groove 5 A self-absorbing oil metal 7 is arranged inside, and the self-absorbing oil metal 7 is foamed copper.

[0023] Such as Figure 3~5 As shown, the longitudinal groove of the T-shaped groove 6 is provided with a spacer 8, one side of the spacer 8 is provided with an arc-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com