Preparation method of chitosan/cellulose acetate/iron composite adsorbent used for removing antimony

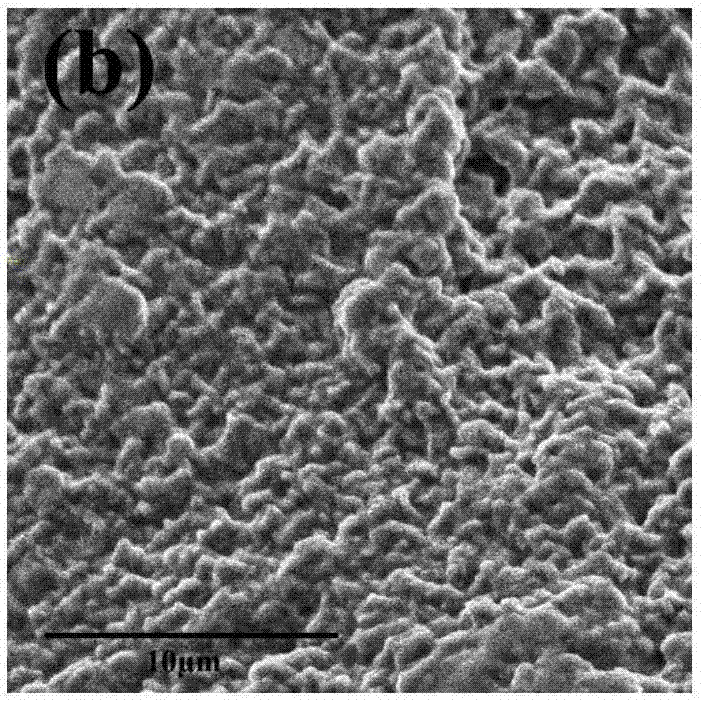

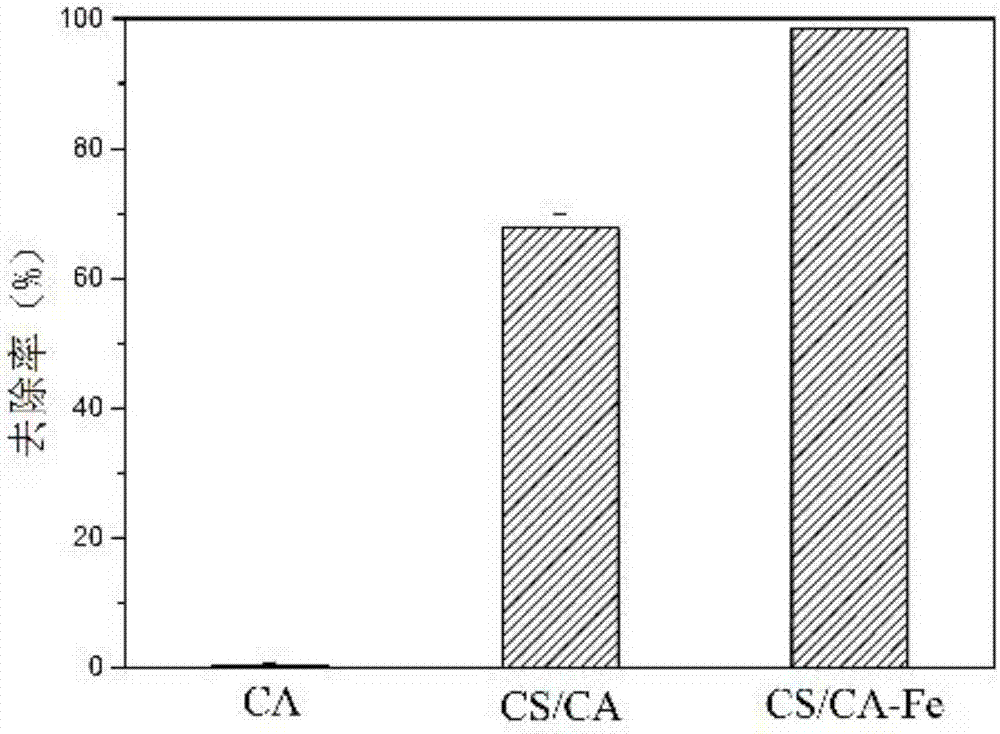

A technology of cellulose acetate and composite adsorption, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor mass transfer rate of low-concentration antimony, poor stability of chitosan, Small specific surface area and other problems to achieve the effect of solving large head loss, strong adsorption activity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The invention provides a kind of preparation method of the chitosan / cellulose acetate / iron composite adsorbent that is used for removing antimony, it comprises the following steps:

[0055] Step 1, dissolving chitosan and cellulose acetate in formic acid solution, fully dissolving to obtain chitosan / cellulose acetate formic acid solution, the mass fraction of the chitosan is 0.5%~10%, the cellulose acetate The mass fraction is 5% to 15%;

[0056] Step 2, dissolving the ferric salt in the chitosan / cellulose acetate formic acid solution prepared in step 1, fully stirring to make it evenly mixed, the mass fraction of the ferric salt is 0.03% to 8%, statically home defoaming;

[0057] Step 3, preparing a sodium hydroxide solution with a mass fraction of 4% to 25%, and maintaining a continuous and slow stirring state;

[0058] Step 4, drop the solution prepared in step 2 into the sodium hydroxide solution described in step 3 with a syringe, continue to stir for 24 hours af...

Embodiment 1

[0062] A preparation method for chitosan / cellulose acetate / iron composite adsorbent for antimony removal, comprising the following steps:

[0063] Step 1, dissolve 3g chitosan and 12g cellulose acetate in 100mL formic acid solution, fully dissolve to obtain chitosan / cellulose acetate formic acid solution, the mass fraction of chitosan is 2%, the content of cellulose acetate is 8.7%;

[0064] Step 2, 0.5g ferric chloride hexahydrate is dissolved in the chitosan / cellulose acetate formic acid solution that step 1 makes, fully stirs and it is mixed evenly, the massfraction of ferric chloride hexahydrate is 0.36%, Static defoaming;

[0065] Step 3, prepare sodium hydroxide solution, the mass fraction is 16%, and maintain a continuous and slow stirring state;

[0066] Step 4, drop the solution prepared in step 2 into the sodium hydroxide solution described in step 3 with a syringe, continue to stir for 24 hours after all the solutions are dripped, solidify in the lye to form partic...

Embodiment 2

[0071] A preparation method for chitosan / cellulose acetate / iron composite adsorbent for antimony removal, comprising the following steps:

[0072] Step 1, 3g chitosan and 12g cellulose acetate are dissolved in 100mL formic acid solution, fully dissolve to obtain chitosan / cellulose acetate formic acid solution, the massfraction of chitosan is 2%, the massfraction of cellulose acetate is 8.7%;

[0073] Step 2, dissolving 1g of ferric salt in the formic acid solution of chitosan / cellulose acetate prepared in step 1, fully stirring to make it evenly mixed, the mass fraction of iron is 0.7%, and standing for defoaming;

[0074] Step 3, prepare sodium hydroxide solution, the mass fraction is 16%, and maintain a continuous and slow stirring state;

[0075] Step 4, drop the solution prepared in step 2 into the sodium hydroxide solution described in step 3 with a syringe, continue to stir for 24 hours after all the solutions are dripped, solidify in the lye to form particles, and use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com