Cleaning pool mechanism for patch rectifier bridge solvent-type circuit board cleaning machine

A rectifier bridge, solvent-based technology, applied in the cleaning methods, cleaning methods and utensils using liquids, and the processing of insulating substrates/layers, etc., can solve the problems of low efficiency, human health damage, and no guarantee of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

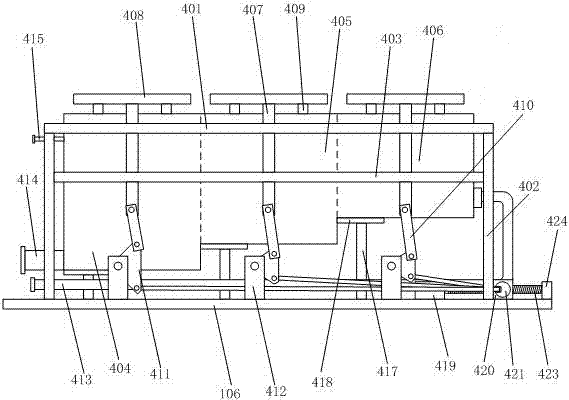

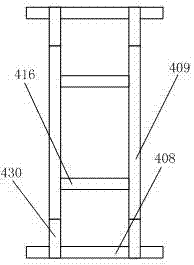

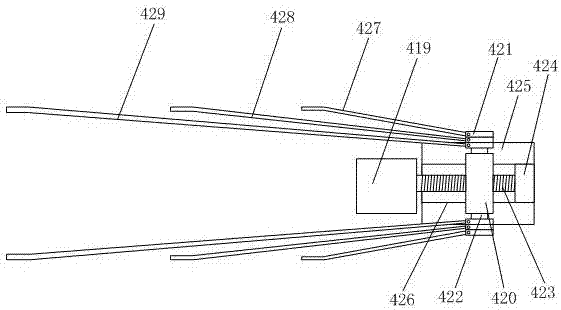

[0013] Such as Figure 1-3 As shown, the cleaning pool mechanism for the patch rectifier bridge solvent-type circuit board cleaning machine disclosed by the present invention includes a cleaning combination pool, a frame bracket, three lifting brackets, and a lifting drive mechanism; the cleaning combination pool includes an integrated rough cleaning pool 404 , fine cleaning tank 405 and rinsing tank 406; rough cleaning tank 404, fine cleaning tank 405 and rinsing tank 406 are connected successively, and the height of the bottom of rough cleaning tank 404, fine cleaning tank 405 and rinsing tank 406 rises successively; The bottoms of pool 404, fine washing pool 405 and rinsing pool 406 are all provided with a bottom bearing plate 418, and under each bottom bearing plate 418, a support column 417 supported on the base plate 106 is provided; the frame support includes a rectangular frame 401 and four supporting legs 402; the upper ends of the four supporting legs 402 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com