Active layer, thin-film transistor array substrate comprising the same, and display device comprising the same

A technology of thin film transistors and array substrates, applied in the field of display devices, can solve the problems of high cost of polysilicon and low on/off ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

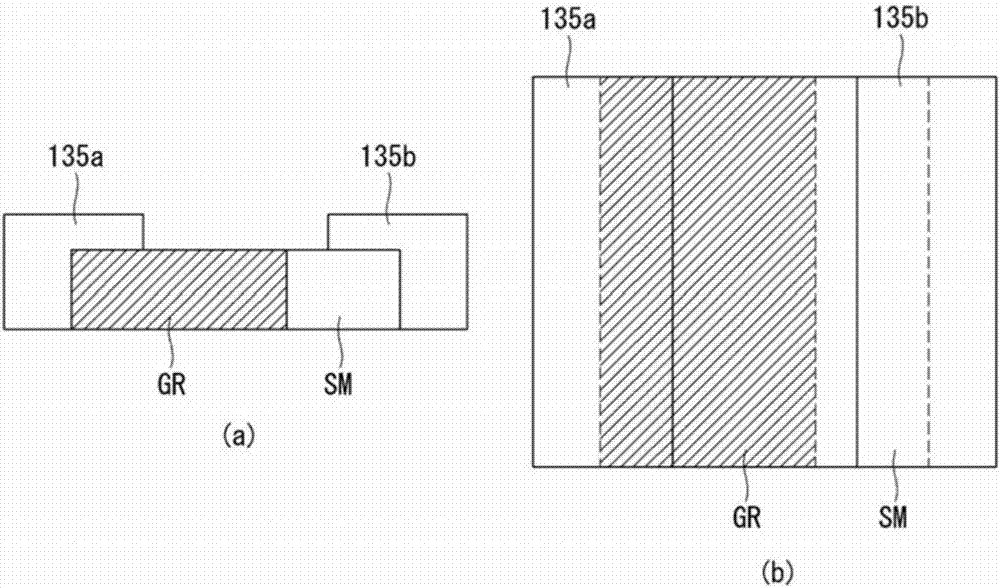

[0092] as above figure 2 As shown, a thin film transistor is fabricated by forming an active layer including a semiconductor material portion and a carbon allotrope portion in a bottom gate type thin film transistor. The semiconductor material portion is made of IGZO (ie, Indium Gallium Zinc Oxide). The optical image of the TFT is shown in Figure 11 ,From Figure 11 It can be clearly seen that a thin film transistor comprising a semiconductor material portion and a carbon allotrope portion was fabricated.

Embodiment 2

[0102] as above Figure 4 As shown, a thin film transistor is fabricated by forming an active layer including a semiconductor material portion and a carbon allotrope portion in a bottom gate type thin film transistor. Semiconductor material components are made of IGZO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com