Resistance box with convenience in air guiding and heat dissipating

A resistance box and air guide technology, applied in the direction of resistors, resistor parts, resistor shells/packaging shells/potting, etc., can solve the problems of fan cost increase, large power, high cost, etc., to avoid excessive temperature concentration High, reduce the loss of air volume, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

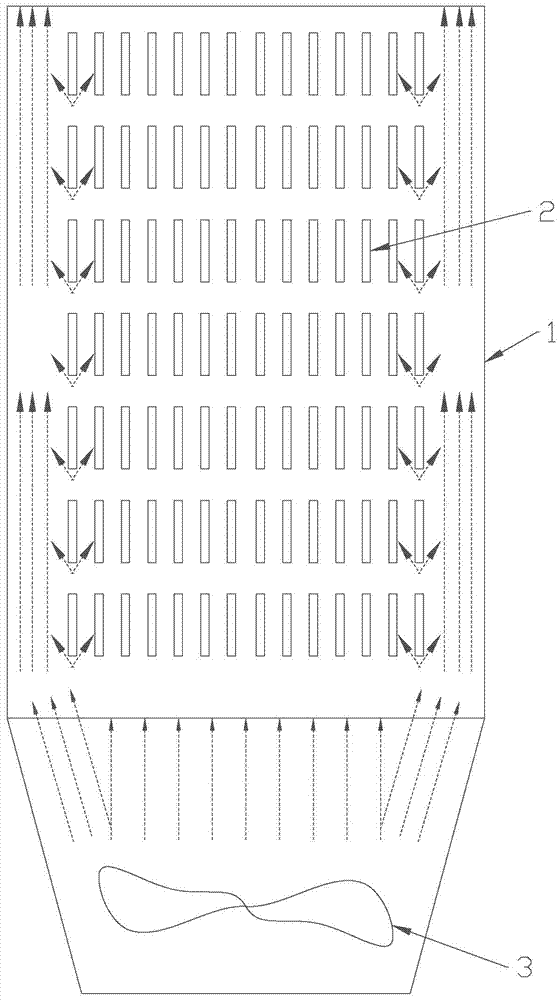

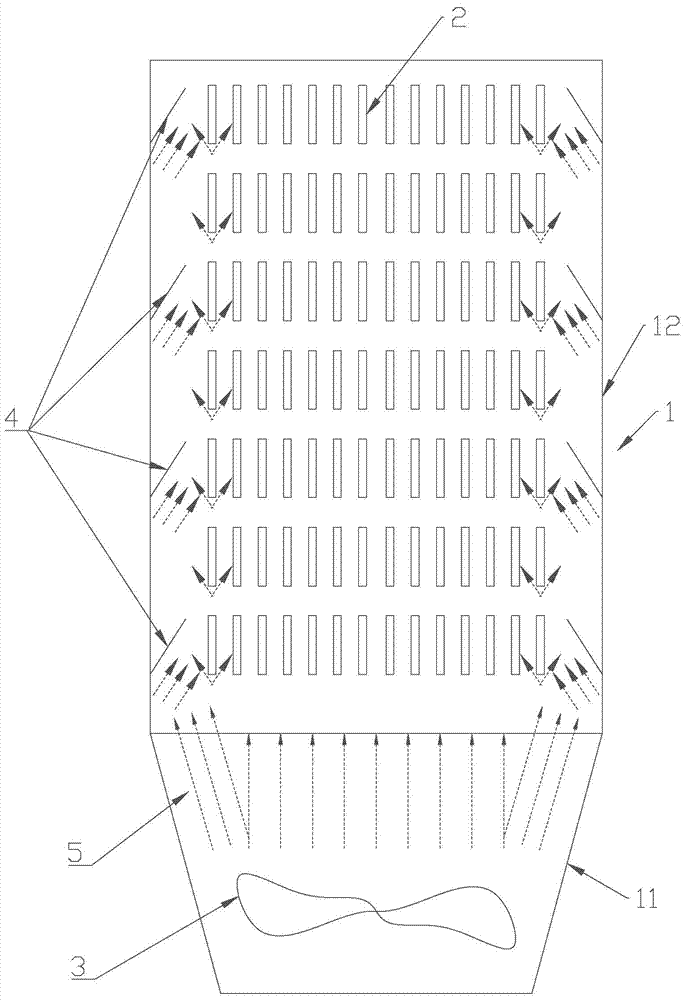

[0023] A kind of resistance box that is convenient to conduct wind and dissipate heat in this embodiment, such as figure 2 As shown, it includes a box body 1 that is hollow to form an inner cavity. The box body 1 includes a continuous bearing section 11 and an accommodating section 12. The accommodating section 12 is used to place the resistance element 2. The upper end of the accommodating section 12 is open for ventilation. There is a certain gap between the elements 2, and the inside of the carrying section 11 is provided with a fan 3 for blowing towards the accommodating section 12, and the fluid blown out by the fan 3 is as figure 2 Indicated by the dotted arrow 5. The cross section of the accommodating section 12 is quadrilateral, and each inner wall of the accommodating section 12 is provided with a plurality of air guides 4, and the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com