Coupling structure of optical fiber array and PD array

A technology of fiber array and coupling structure, applied in the field of coupling structure, can solve the problems of incompetence of discrete methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

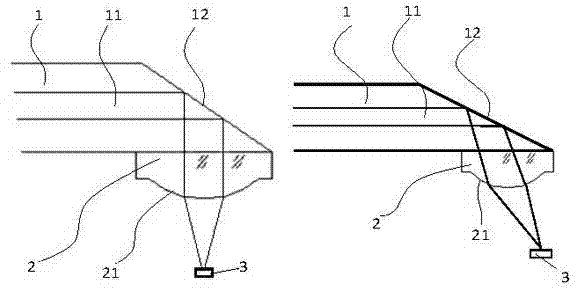

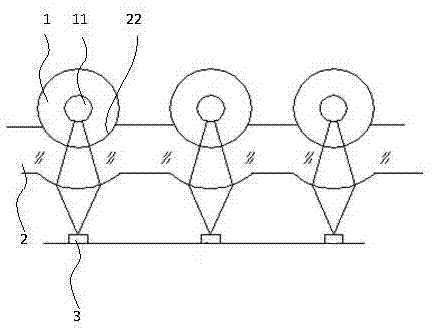

[0016] Depend on figure 1 and 2 As shown, a coupling structure between an optical fiber array and a PD array includes an optical fiber array 1 , a lens array 2 and a PD array 3 .

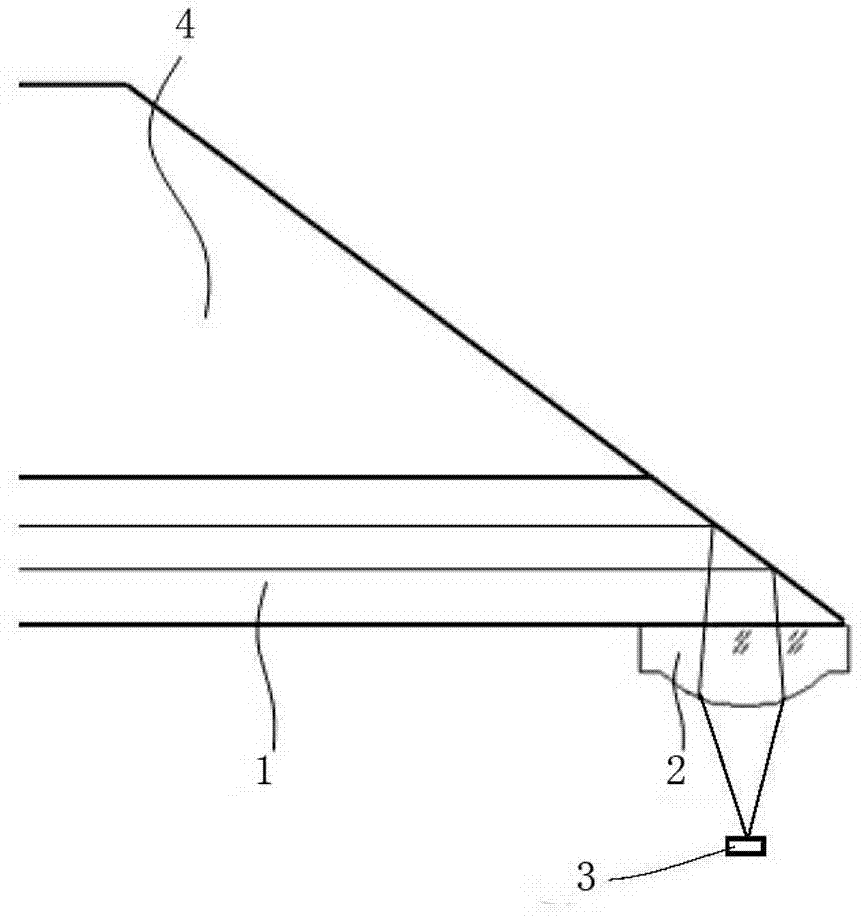

[0017] Optical fiber array 1, including several optical fibers, can be 1×4, 1×8, 1×12 core optical fibers or more, which are fixed in equal-spaced V-shaped grooves set on the glass block 4, and the end faces of the optical fiber array 12 It is ground into a certain angle with the vertical direction, depending on the material refractive index of the optical fiber used, and the total reflection angle calculated accordingly. The end face angle can be less than, equal to or greater than the total reflection angle. When it is smaller than the total reflection angle, A layer of high reflection film needs to be coated on the end surface to realize the total internal ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com