A composite detection underwater robot welding seam defect detection device

An underwater robot and composite detection technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the detectable area of underwater image signals is limited due to the underwater environment, the autonomous control is not strong, and the activity area is restricted. , to achieve the effect of enhancing autonomy and controllability, reducing underwater resistance and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

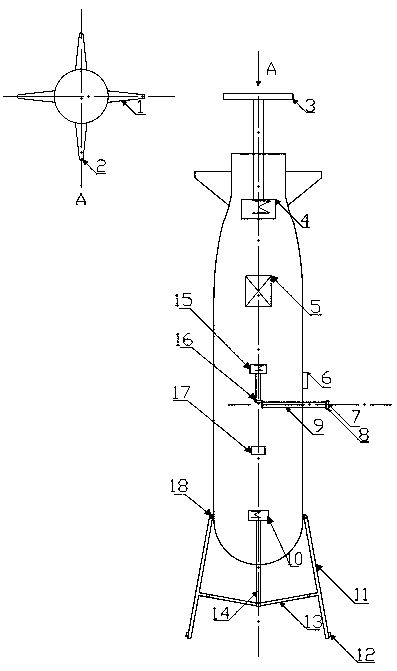

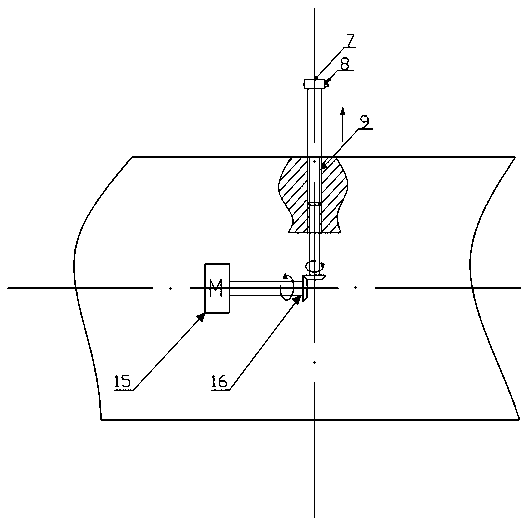

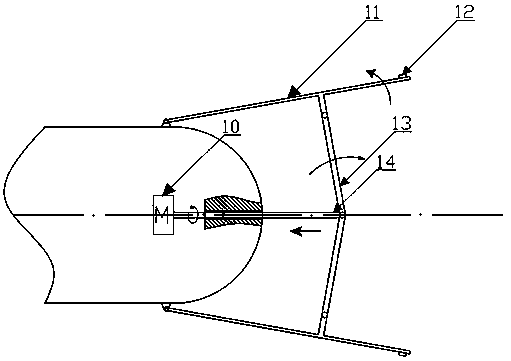

[0018] Combine below figure 1 , 2 , 3, 4, 5 further illustrate the device of the present invention.

[0019] In the process of welding seam detection by underwater robots on offshore platforms, the underwater robots are first put into the water in the sea area near the offshore platform. After the underwater robot enters the water, the controller (5) starts the propeller motor drive module (4) to rotate to drive the propeller (3) to rotate, and the device starts to propel in the water. When the positioning coordinates of the GPS positioning module (6) reach the approximate area, the controller (5) starts the telescopic link motor drive module (15). The telescopic link motor drive module (15) makes the steering gear rod τ5 (16) rotate horizontally, and drives the steering gear threaded rod τ1 (9) to rotate vertically through the meshing of the steering gear. Steering gear threaded rod τ1 (9) stretches out due to threaded connection, and controller (5) starts CCD camera (7) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com