Experimental device and experiment method for breaking rock by means of ultrasonic waves

An experimental device and rock crushing technology, which is applied in the cross field of ultrasonics and rock crushing, can solve the problems of low penetration rate, low drilling strength, wear and tear of equipment, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

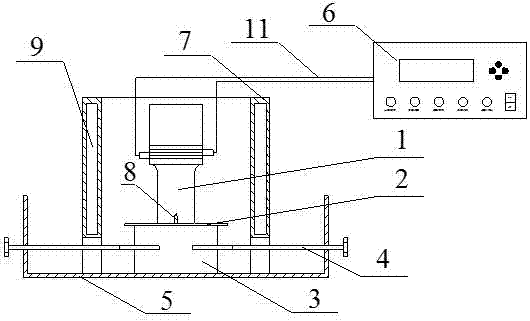

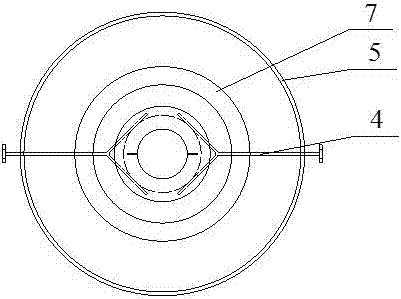

[0030] A kind of experiment device that utilizes ultrasonic wave to excite broken rock of the present invention is made up of ultrasonic generator 6, vibrating system and cooling system three parts, and vibrating system comprises Lang Jiewen vibrator 1, connecting plate 2 and fixator 4, and cooling system comprises There are cooling cylinder 7, cooling liquid 9 and cooling tank 5.

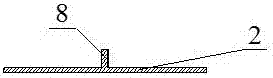

[0031] The connecting piece 2 and the Langevin vibrator 1 are screwed together through the screws 8 on the connecting piece 2, and then the rock specimen 3 and the connecting piece 2 are tightly bonded together with superglue.

[0032] The ultrasonic transducer in the vibrator 1 is a composite piezoelectric ceramic transducer.

[0033] The connecting piece 2 is circular, and its diameter and thickness are determined according to the diameter of the experimental specimen.

[0034] Utilize the symmetrical "Y" type fixer 4 that is installed on the tank wall of the cooling tank to clamp the rock speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com