A water-saving rock or concrete cylindrical sample making device

A technology for making a device and concrete, applied in the field of geotechnical engineering instruments, can solve problems such as difficulty in grasping the depth of drilling tools, uneven sides of cylindrical samples, waste of materials, manpower, time, etc., so as to improve production efficiency and expand Limitations and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

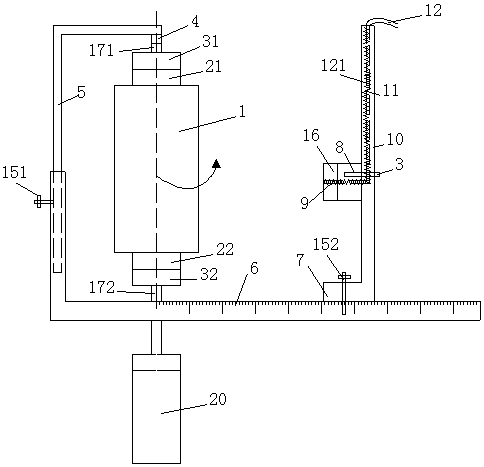

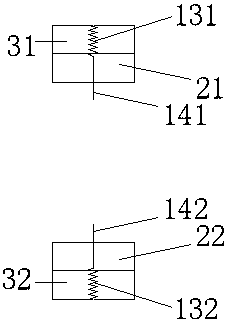

[0031] Such as figure 1 As shown, it includes a rack, which is characterized in that: the rack includes a horizontal rail 6, a vertical column 2, a sliding rod 5, the vertical column 2 is a hollow structure, and the sliding rod 5 includes a first vertical section and a first vertical section. Two cantilever sections, the first vertical section is slidably arranged in the hollow structure of the vertical column 2, and a fixing member is arranged between the first vertical section and the vertical column 2; the fixing member It is a first threaded bolt 151, the vertical column 2 is provided with a first threaded hole, and the first threaded bolt 151 cooperates with the first threaded hole to resist and fix the first vertical section.

[0032] The vertical column 2 and the sliding rod 5 can be slid up and down to adjust the installation space of the specimen conveniently, and the specimen 1 of any height can be produced according to the needs, and the sliding rod 5 after the adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com