Device and production process for producing 5N-grade high-purity propane by adopting double-tower continuous rectification

A high-purity propane, rectification technology, applied in the direction of solidification, lighting and heating equipment, refrigeration and liquefaction, etc., can solve the problems of high-purity propane low purity, low thermodynamic efficiency, high energy consumption of rectification, etc., to reduce energy consumption , low investment cost, and the effect of simplifying the refrigeration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

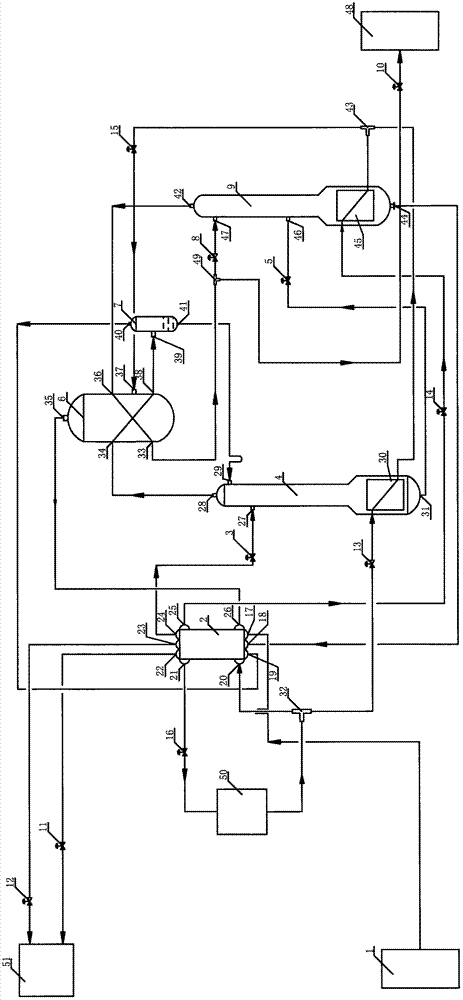

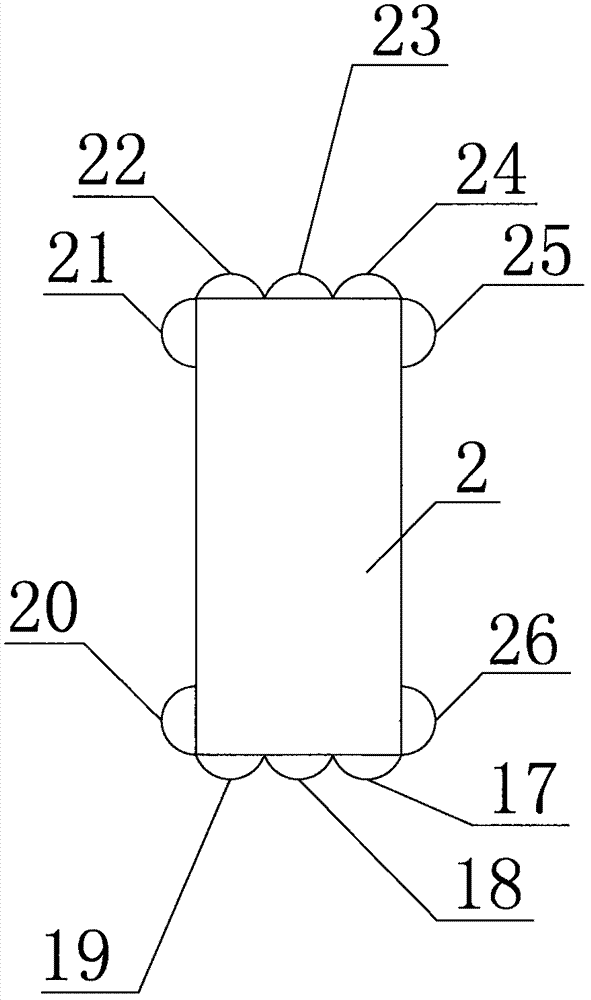

[0030] A device for producing 5N-grade high-purity propane by double-tower continuous rectification, including a raw material liquid storage tank 1, a product storage tank 48, a refrigeration device 50, and an exhaust gas furnace 51. The raw material liquid storage tank 1 is connected to the first heat exchanger 2 through pipelines The first raw material inlet 17 of the first heat exchanger 2 is connected to each other, the first raw material outlet 24 of the first heat exchanger 2 is connected to the first raw material inlet 27 of the first rectifying tower 4 through the first regulating valve 3, and the gas phase at the top of the first rectifying tower 4 Outlet 28 links to each other with the first raw material gas inlet 34 of second heat exchanger 6 through pipeline, and the first raw material outlet 38 of second heat exchanger 6 links to each other with the raw material inlet 39 of gas-liquid separator 7 through pipeline, and gas-liquid separator The liquid phase outlet 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com