Concurrent operation high-speed railway separated line roadbed structure and construction method thereof

A technology for high-speed railways and construction methods, applied in infrastructure engineering, roads, buildings, etc., can solve problems such as subsidence, deformation, and offset of operational roadbeds, and achieve the effects of reducing project costs and avoiding equipment encroachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

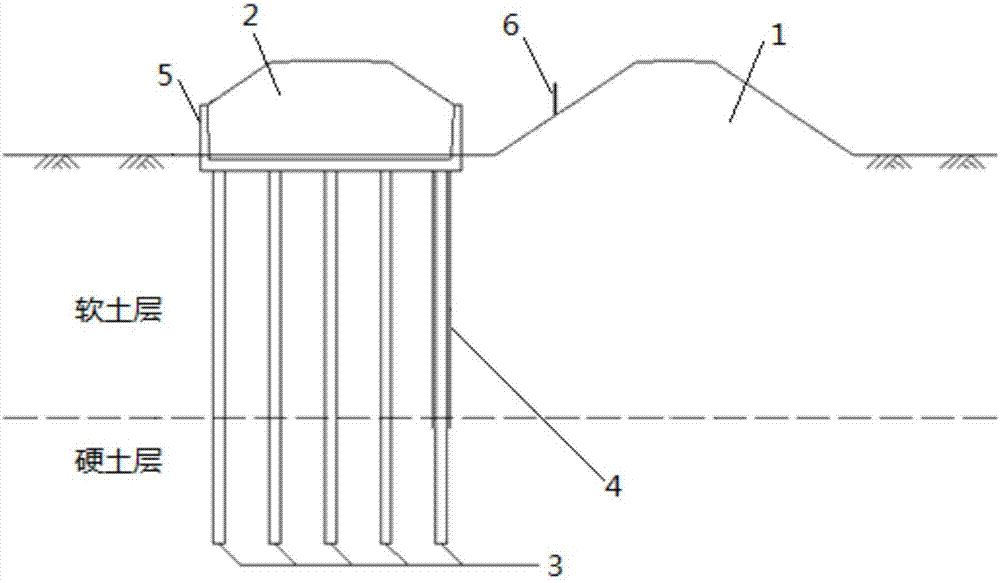

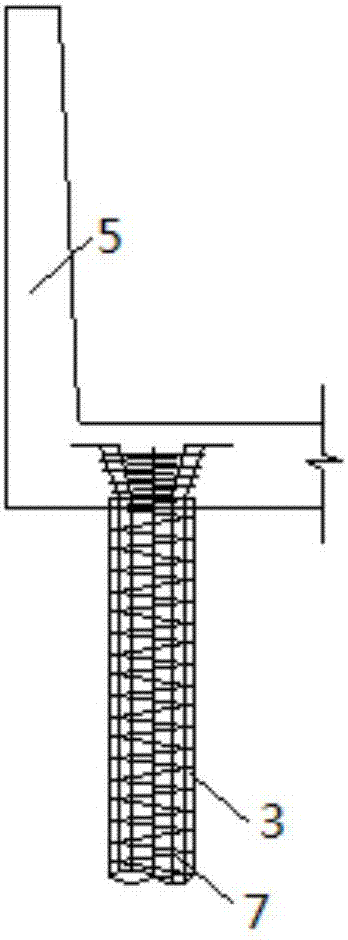

[0031] like figure 1 As shown, the subgrade structure of the separated high-speed railway in parallel operation includes multiple rows of bored piles 3 uniformly distributed along the width direction of the new railway subgrade 1, and each row of bored piles 3 includes a plurality of bored piles 3 uniformly distributed along the length direction of the railway subgrade. The bottom of the bored pile 3 penetrates the soft soil layer to the hard soil layer or rock layer at the bottom, and the top of the bored pile 3 is laid with a 0.1-0.2m thick concrete cushion, and a reinforced concrete U-shaped groove 5 is arranged on the concrete cushion , the top of the bored pile 3 is embedded in the bottom plate of the reinforced concrete U-shaped groove 5, and is rigidly connected with the bottom plate of the reinforced concrete U-shaped groove 5, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com