A kind of heavy oil processing method

A processing method and technology for heavy oil, which are applied in the petroleum industry, hydrotreating process, treatment of hydrocarbon oil, etc., can solve the problems of low yield of light oil, poor quality of catalytically cracked gasoline and diesel oil, etc., and improve the yield and quality. , the effect of increasing the added value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

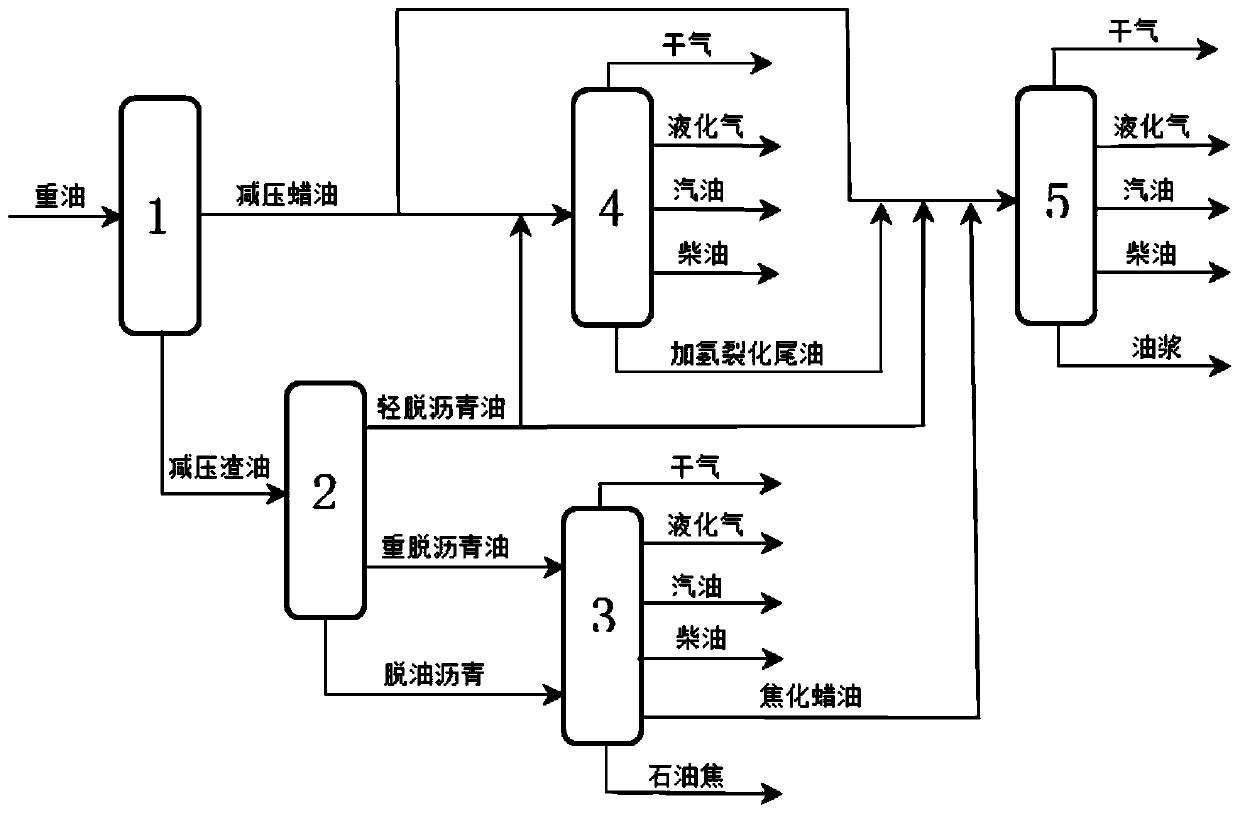

Method used

Image

Examples

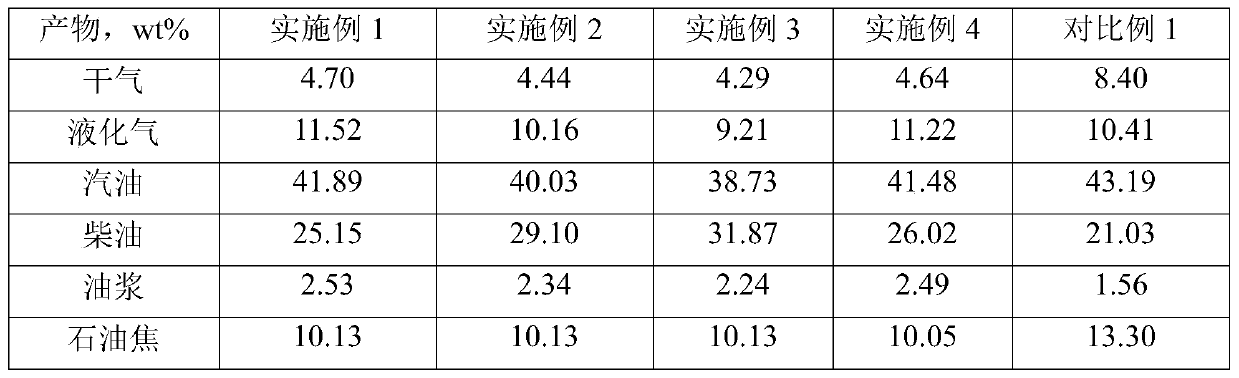

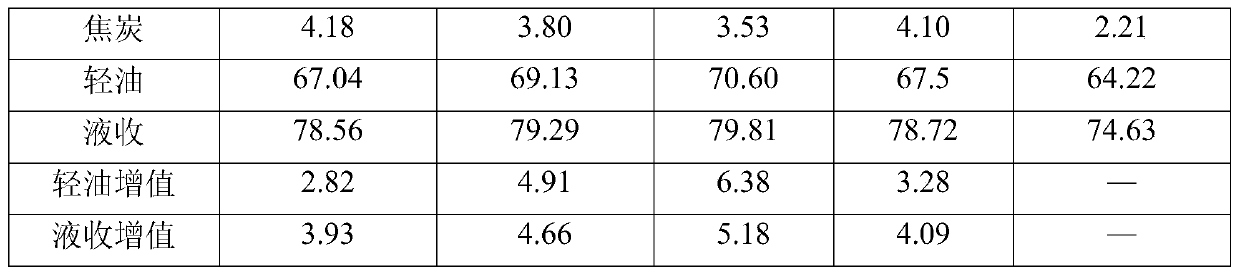

Embodiment 1

[0045] This example is used to illustrate the heavy oil processing method using PZ as raw material.

[0046] PZ is subjected to vacuum distillation treatment through vacuum distillation device 1 to obtain VGO 1 and VR 1 , VGO 1 with VR 1 The specific properties of are shown in Table 2;

[0047] With isobutane as solvent, 20 parts by weight of VR 1 and 80 parts by weight of isobutane at a temperature of 90°C and a pressure of 4MPa to carry out solvent directional separation treatment through a solvent directional separation device 2 to obtain LDAO 1 、HDAO 1 and DAOs 1 , LDAO 1 、HDAO 1 and DAOs 1 The yield is shown in Table 3, LDAO 1 The properties of are shown in Table 4;

[0048] HDAO 1 and DAOs 1 Under the conditions of temperature 500°C, pressure 0.2MPa, and circulation ratio 0.2, carry out delayed coking treatment through delayed coking unit 3 to obtain dry gas, liquefied gas, gasoline, diesel oil, coker wax oil and petroleum coke;

[0049] 90 parts by weight ...

Embodiment 2

[0053] This example is used to illustrate the heavy oil processing method using PZ as raw material.

[0054] Process heavy oil according to the method of embodiment 1, the difference is that 80 parts by weight of VGO 1 and 20 parts by weight LDAO 1 undergo hydrocracking treatment.

[0055] The product distribution of Example 2 is shown in Table 5.

Embodiment 3

[0057] This example is used to illustrate the heavy oil processing method using PZ as raw material.

[0058] Process heavy oil according to the method of embodiment 1, the difference is that 70 parts by weight of VGO 1 and 30 parts by weight LDAO 1 undergo hydrocracking treatment.

[0059] The product distribution of embodiment 3 is shown in table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com