Method for treating pollution in microalgae culture process

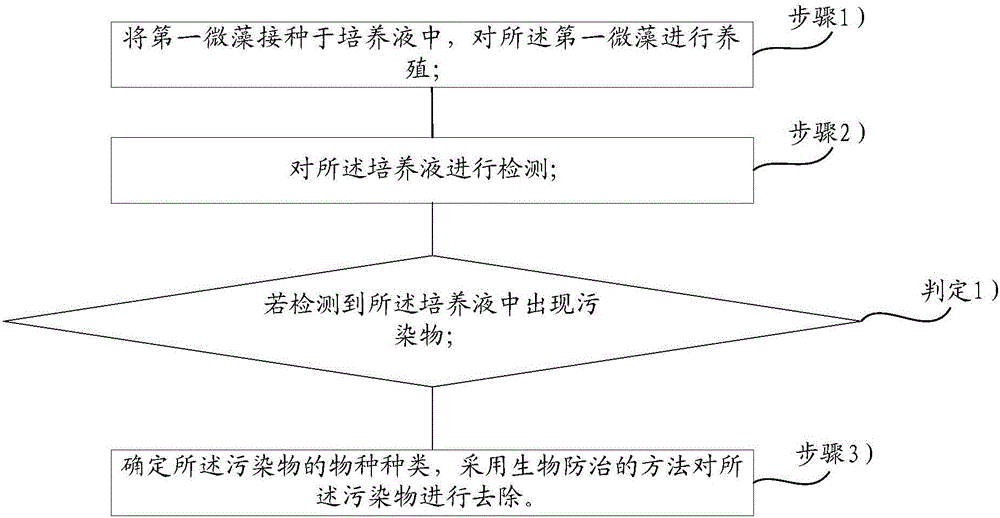

A technology of microalgae and pollutants, which is applied in the field of pollution control in the process of microalgae cultivation, and can solve the problems of microalgae death, secondary pollution of microalgae, difficulty in recovering growth of microalgae, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In Example 1, Chlorella was used as the cultured algae species. During the culture process of Chlorella, under the same culture conditions, the output of Chlorella was reduced by 30%, and the culture medium was observed through a microscope to find that there was A large number of bacteria, take a certain amount of culture fluid samples, carry out optical density (OD) detection to the supernatant after filtering and removing the chlorella cells, the OD value obtained by detection is 0.2, and the density of 200,000 / ml is added to the Add flagellates to the culture solution, continue to breed, and detect the output of the chlorella and the number of the bacteria. After 2 days, the number of bacteria is significantly reduced. The chlorella cells are removed by filtration, and the supernatant is tested again for optical density. The resulting OD value was 0.1. Among them, OD represents the optical density absorbed by the detected substance.

[0077] The production of micro...

Embodiment 2

[0079] Said embodiment 2 uses Nannochloropsis pseudochloropsis as cultured algae species, in the process of cultivating Nannochloropsis pseudochloropsis, under the same cultivation conditions, the output of Nannochloropsis pseudochloropsis is reduced by 20%, and a large amount of pollution in the culture solution is found Bacteria, after filtering to remove the algae cells, the OD value of the remaining clear liquid is 0.2; add ciliates that have little influence on the growth of the Nannochloropsis algae to the culture solution at a density of 200,000 / ml, and continue to breed , and detected the output of the Nannochloropsis pseudochloropsis and the number of each species, 2 days later, the number of bacteria was significantly reduced, the clear night OD value after filtering the algae cells was 0.1, and the number of ciliates increased to 300,000 / ml.

[0080] Continue to cultivate for 2 days, the number of ciliates increases to 500,000 / ml, and the output of Nannochloropsis ps...

Embodiment 3

[0082]Described embodiment 3 uses Xanthophyllum as cultured algae, in the process of cultivating Xanthophyllum, under the same cultivation conditions, the output of Xanthophyllum is reduced by 20%, and it is found that the cyanobacteria in the culture solution are polluted by microscopic examination. Reach 1,000,000 / ml, add ciliate (because the cell wall of described Xanthophyllum is thicker, ciliate cannot prey on described Xanthophyllum) with the density of 300,000 / ml to described culture medium, culture After 3 days, the number of cyanobacteria was reduced to 300,000 / ml, and a large number of broken filaments occurred. The 300-mesh silk sieve was used to filter and continue to cultivate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com