Windproof bridge crane anchoring system and method

An anchoring and bridge crane technology, which is used in transportation and packaging, load hanging components, trolley cranes, etc., can solve the problems of windproof anchoring that is not suitable for automation, remote operation, multi-manpower, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

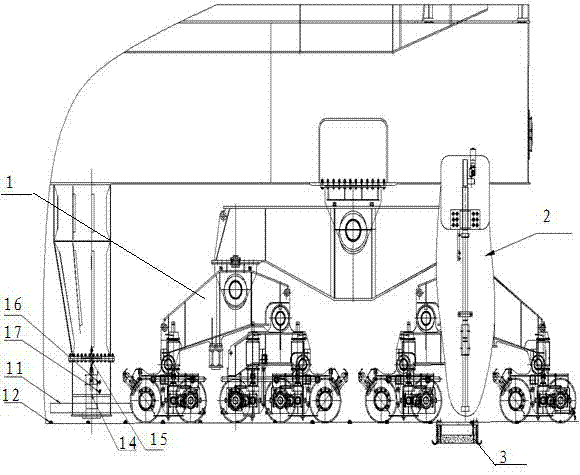

[0025] Such as figure 1 As shown, the bridge crane windproof anchoring system proposed by the present application includes a bridge crane 1, four windproof pull rods 2 (only one is shown in the figure) that are respectively arranged at the two ends of the sea side and the land side of the bridge crane, and four Four sets of ground windproof foundations 3 (only one is shown in the figure) and windproof anchor control modules (not shown in the figure) are respectively corresponding to the four windproof pull rods; the ground windproof foundation 3 is fixed on the pier foundation.

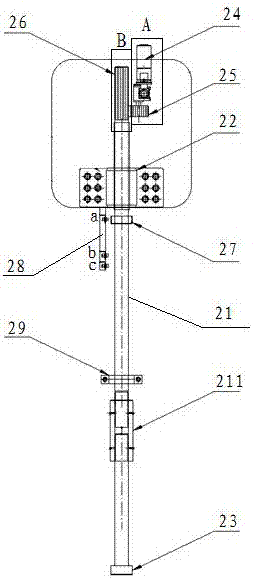

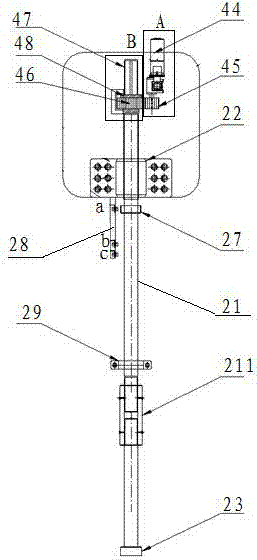

[0026] Such as figure 2 As shown, the windproof pull rod 2 includes a pull rod body 21, a pull rod nut 22, a drive device A and a lock pin 23; the drive device A is connected to the control output end of the windproof anchor control module; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com