Rice-seed-film-mulching and direct-sowing machine

A direct seeding machine and film covering technology, which is applied in the field of agricultural machinery, can solve the problems affecting the effect of direct seeding of rice covered with film and grain production, the inability of seeds and soil to be in close contact, and the inability of rice seeds to touch the soil, etc., to eliminate the phenomenon of seed film suspension , enhance soil fluidity, and ensure the effect of grain production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

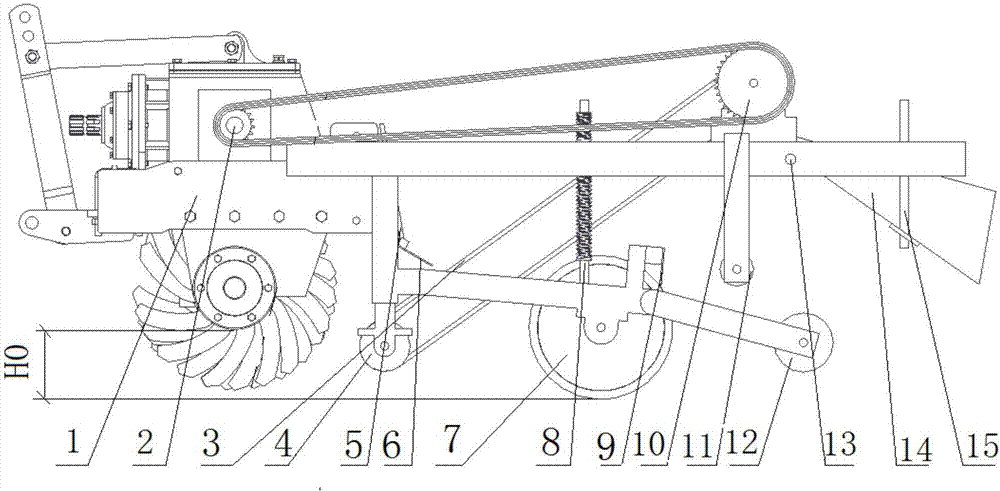

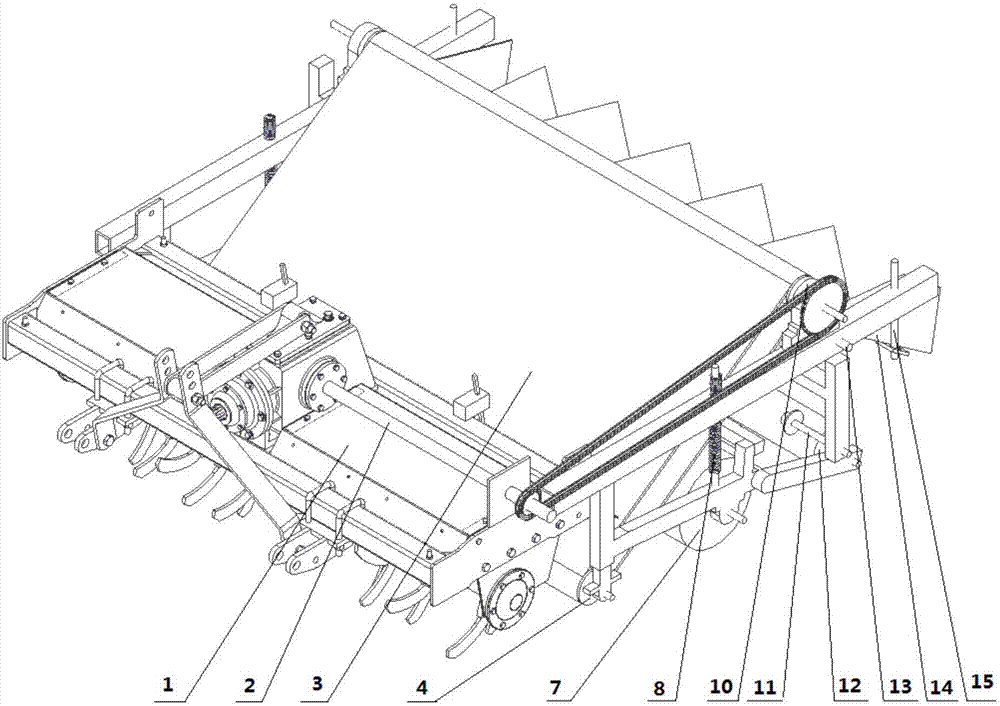

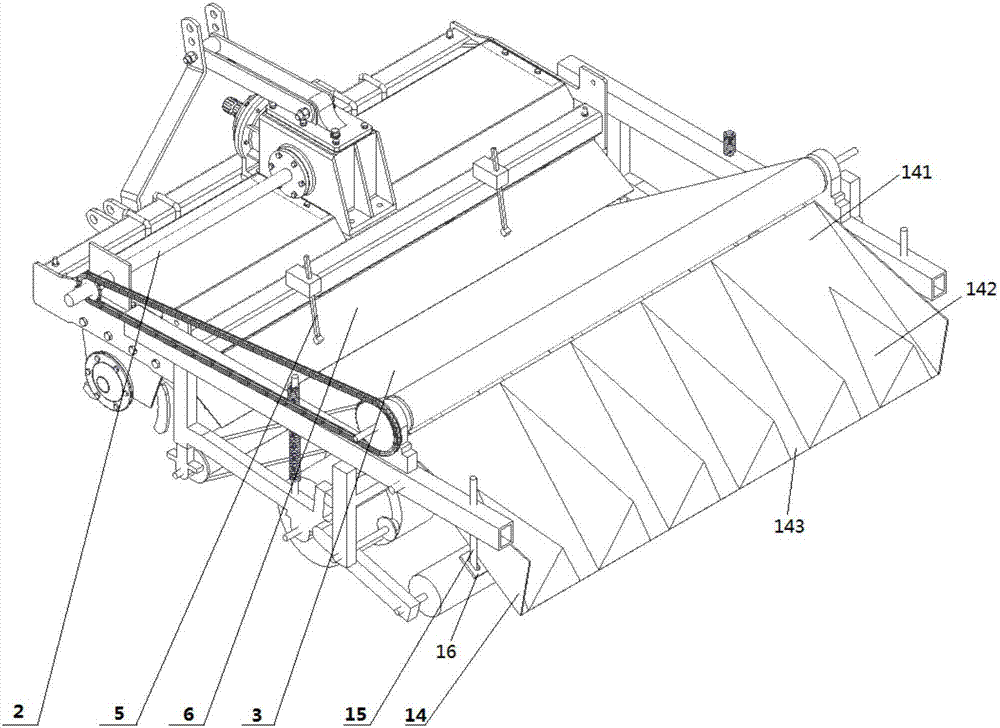

[0029] Embodiment 1: as Figure 1-Figure 3 As shown, the present invention includes a frame, a rotary tillage and crushing device 1, a pressing roller 7, a soil covering conveying device, a shunting guide device 14 and a seed film coating device, and the rotary tilling and crushing device 1 and the suppressing roller are sequentially arranged below the frame 7. The seed film coating device, the rotary tillage and soil breaking device 1 is arranged under the frame at the front end of the work, and the soil is rotary cultivated; the seed film film coating device is set under the frame at the rear end of the work, and the shunt guide device 14 is set above the frame The covering soil conveying device is obliquely arranged on the frame between the rotary tillage and crushing device 1 and the seed film covering device, the soil after the rotary tillage and crushing device 1 is thrown to the covering soil conveying device, and the covering soil is dropped by the covering soil diversi...

Embodiment 2

[0038] Embodiment 2: The difference between this example and Embodiment 1 is that the transmission wheel in this example is a belt pulley, and the transmission parts are a plurality of belts arranged side by side, so that the rotary tillage and soil breaking device 1 is thrown on the transmission belt, and multiple belts are simultaneously transported The soil is delivered to the diversion guide device 14, and falls after diversion. The angle α between the soil-covering conveyor belt and the horizontal plane is 65°. The included angle β between the diversion groove and the horizontal plane is 80°. The included angle γ between the bottom edge and the side edge of the grooved belt of the pressing roller is 90 degrees, and the height of the boss is 60 mm. The height difference H0 between the mounting bottom surface of the pressing roller and the bottom surface of the rotating shaft of the rotary tillage and soil breaking device is 55mm.

Embodiment 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the transmission wheel in this embodiment is a belt pulley, and the transmission member is formed by a plurality of conveyor chains arranged side by side, and its working principle is the same as that of Embodiment 2; The included angle α is 50°. The included angle β between the diversion groove and the horizontal plane is 60°. The included angle γ between the bottom edge and the side edge of the grooved belt of the pressing roller is 45 degrees, and the height of the boss is 30mm. The height difference H0 between the mounting bottom surface of the pressing roller and the bottom surface of the rotating shaft of the rotary tillage and soil breaking device is 45mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com