A kind of preparation method of lithium ion battery sns2/snsb composite negative electrode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low specific capacity, poor cycle performance and rate performance, and achieve avoidance of agglomeration and improvement of poor conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention proposes a lithium ion battery SnS 2 The preparation method of / SnSb composite negative electrode material comprises the steps:

[0016] Step 1: Weigh SnCl according to the ratio of the amount of substances to 1:2 4 ·5H 2 Add O and thioacetamide to the polyethylene glycol solution, stir well until it is completely dissolved, then transfer the solution into the polytetrafluoroethylene tank of the hydrothermal synthesis reactor, keep it warm at 180°C for 15h, and cool The final product was washed repeatedly with deionized water and ethanol, and dried in vacuum to obtain brown SnS 2 powder;

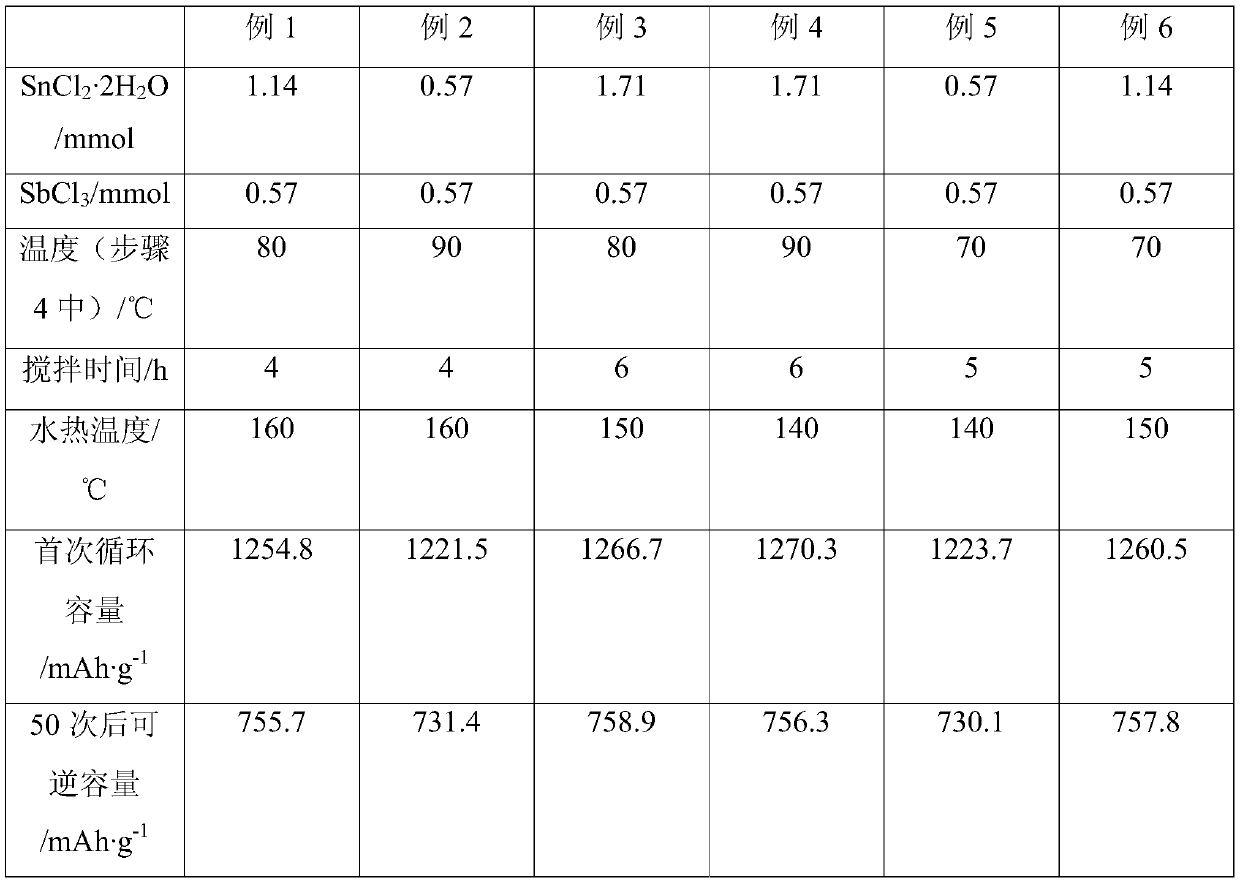

[0017] Step 2: The above obtained SnS 2 The powder was dissolved in absolute ethanol, and SnCl was added 2 2H 2 O and SbCl 3 , adding SnCl 2 and SbCl 3 The ratio of the amount of substances is controlled in SnCl 2 / SbCl 3 =3~1, fully stir until completely dissolved to obtain solution A;

[0018] Step 3: Prepare 0.15mol / L NaBH 4 solution, under magnetic stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com