A kind of insulating glass insulation strip and manufacturing method

A technology for thermal insulation strips and glass, applied in building structures, windows/doors, building components, etc., to achieve the effects of high efficiency, reduced heating energy consumption, and simplified processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

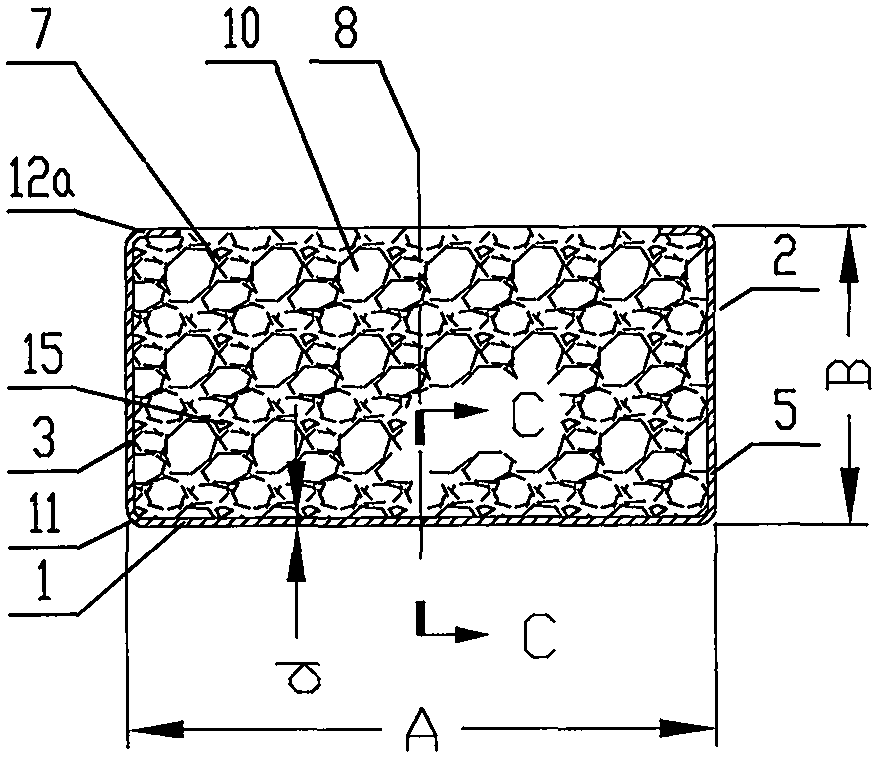

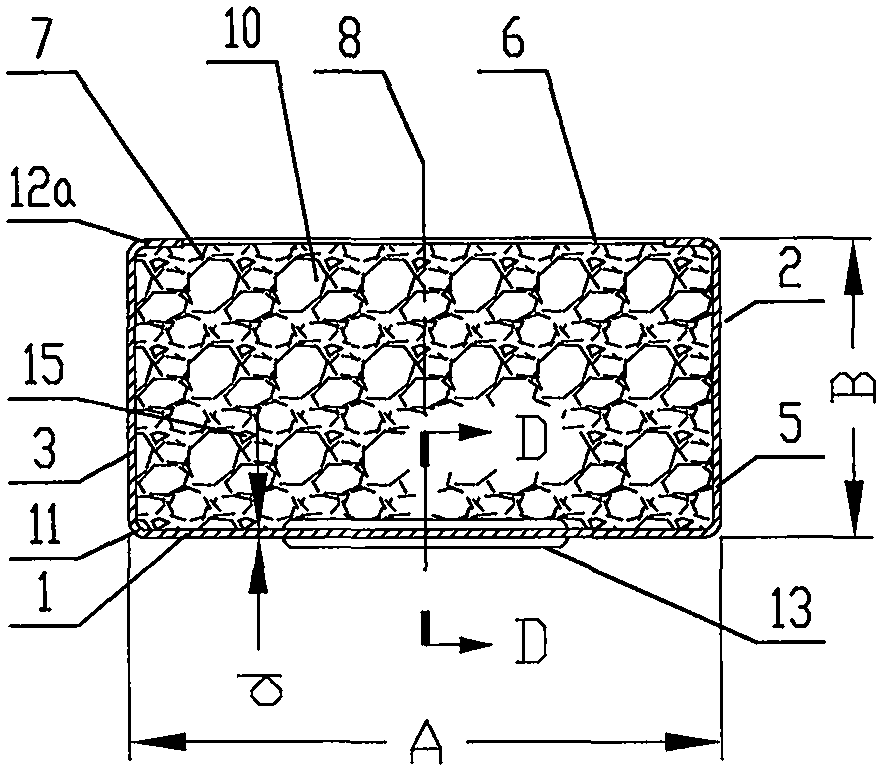

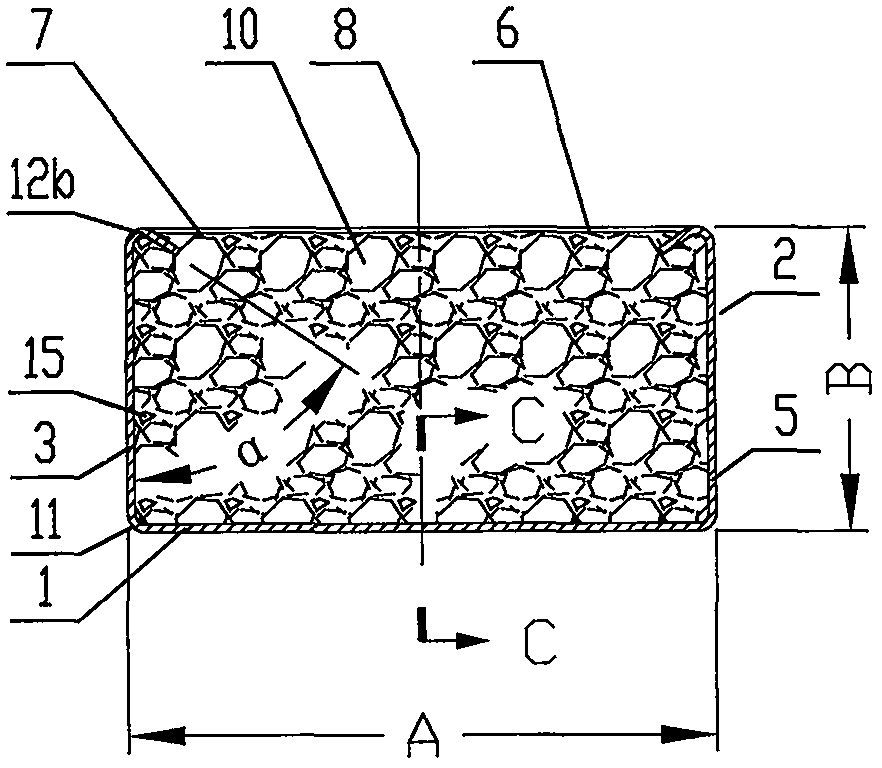

[0058] Specific implementation mode one: as Figure 1-18 Shown is a schematic cross-sectional view of several typical structural forms of the insulating glass insulation strip of the present invention. A insulating strip for insulating glass, comprising a metal strip 2 and a foam strip 10; width A=7-40mm, preferably 7-18mm, height B=5-20mm, preferably 6-10mm; the greater the width, the greater the insulating glass The better the heat insulation effect, the lower the cost performance;

[0059] The metal strip 2 is a long strip with a roughly C-shaped cross-section. The left wall 3 and the right wall 5 connected as a whole are respectively perpendicular to the bottom surface 1, and there is a deformable buffer arc at the junction of the left wall 3, the right wall 5 and the bottom surface 1. 11 or transition arc 4, wherein buffer arc 11 is a single arc, which is connected tangentially to bottom surface 1, left wall 3, and right wall 5 respectively, and the shape of transition a...

specific Embodiment approach 2

[0070] Specific implementation mode two: as Figure 1-18 A schematic cross-section of an insulating bar is shown, Figure 21 A typical example of a rectangular spacer frame 19 is shown. The difference from Embodiment 1 is that a spacer frame 19 is manufactured using the above-mentioned insulating glass insulation strip and is used to manufacture insulating glass; the shape of the spacer frame 19 is rectangular or trapezoidal Or rhombus, circle or ellipse, or a combination of the above shapes, the bend has a bend 22, the exposed surface of the foam strip 10 is on the inner side of the spacer frame 19 (no metal strip surface), the outer dimensions of the spacer frame 19 and the glass 16 Matching; filling the foam strip 10, so that the wrinkles when bending and bending 22 are not obvious, and the product is beautiful.

[0071] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0072] Specific implementation mode three: as Figure 1-19 , as shown in 21, Figure 19 It is a schematic diagram of an insulating glass. The difference from Embodiments 1 and 2 is that a type of insulating glass is two-layer insulating glass, which is manufactured by using the spacer frame 19 described in Embodiment 2. The insulating glass includes glass 16. The spacer frame 19, the spacer frame 19 is between two pieces of glass 16, the insulation strip of insulating glass is set along the edge of the glass 16, the two sides of the spacer frame 19 and between the glass 16 are respectively provided with adhesive 24, along the A sealant 25 is set between the edge of the glass 16 and the metal strip 2 to bond the spacer frame 19 and the glass 16 together, and the desiccant 15 absorbs the moisture in the hollow part 18 through the moisture-absorbing small hole 7, improving the sealing effect of the insulating glass and connection strength to prevent moisture condensation; the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com