Concrete hopper

A concrete and hopper technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficult control of the discharge speed of the concrete hopper and reduction of the load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

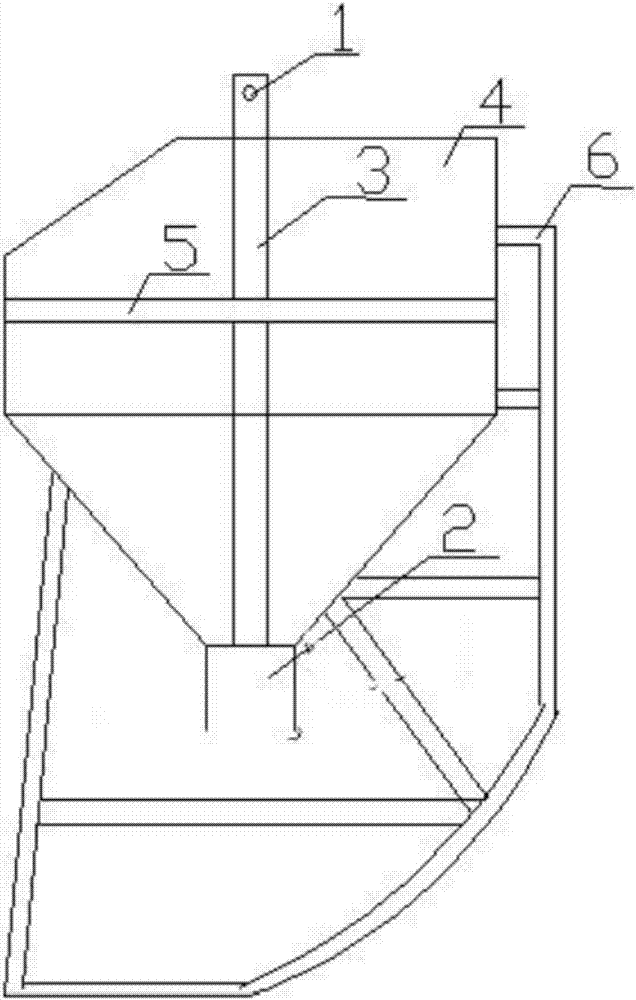

[0021] Such as figure 1 As shown, the concrete hopper includes a hoisting hole 1, a slurry outlet 2, a vertically reinforced steel plate 3, and a hopper body 4. The hopper body 4 is provided with a vertically reinforced steel plate 3 and a transversely reinforced channel steel 5. There is a hoisting hole 1, and the hopper body 4 is connected with the truss base 6 through a transverse reinforcement channel steel 5.

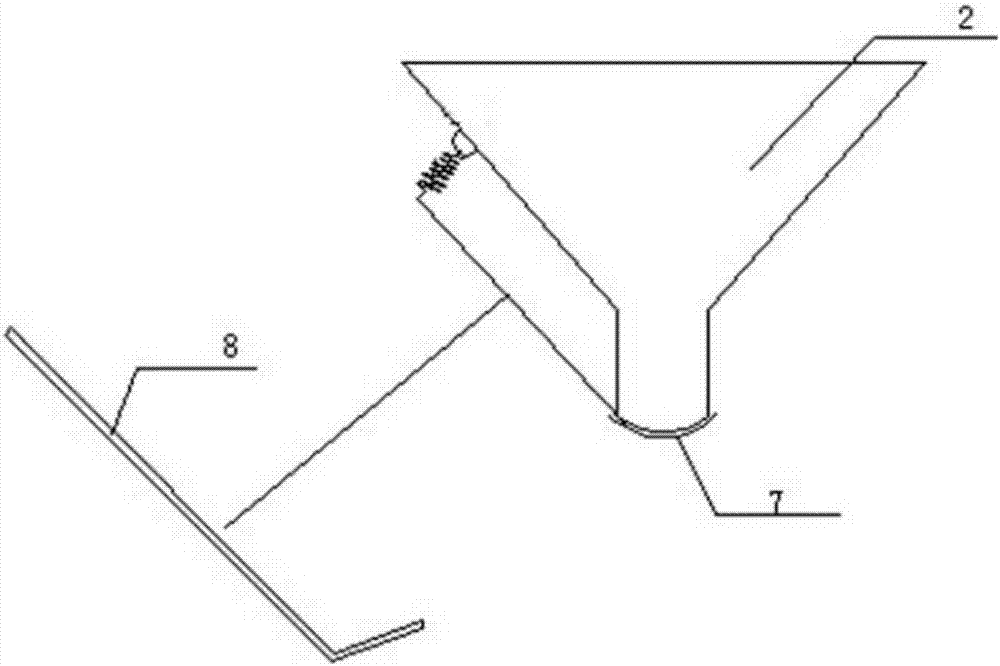

[0022] Such as figure 2 ,Such as image 3 As shown, the lower end of the pulp outlet 2 is provided with a movable fan-shaped plate 7, the pulp outlet 3 is arranged opposite to the fan-shaped plate 7, the handle 8 is connected with the fan-shaped plate 7, and one end of the handle 8 is fixed on the hopper body 4 by a spring, and the handle 8 controls the fan-shaped plate 7 Move in parallel to the slurry outlet 3; when the handle 8 pulls the spring support rod fan-shaped plate 7 in the direction away from the slurry outlet 2 to open, the concrete falls, and when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com