a house structure

A house and integrated technology, applied in the direction of roofs, building components, drainage structures, etc., can solve problems such as prolonging the construction period of houses, troublesome transportation, adverse effects on house stability, etc., and achieve the effect of improving on-site construction efficiency and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further explain the technical solutions of the present invention, a detailed description is given below with reference to the accompanying drawings.

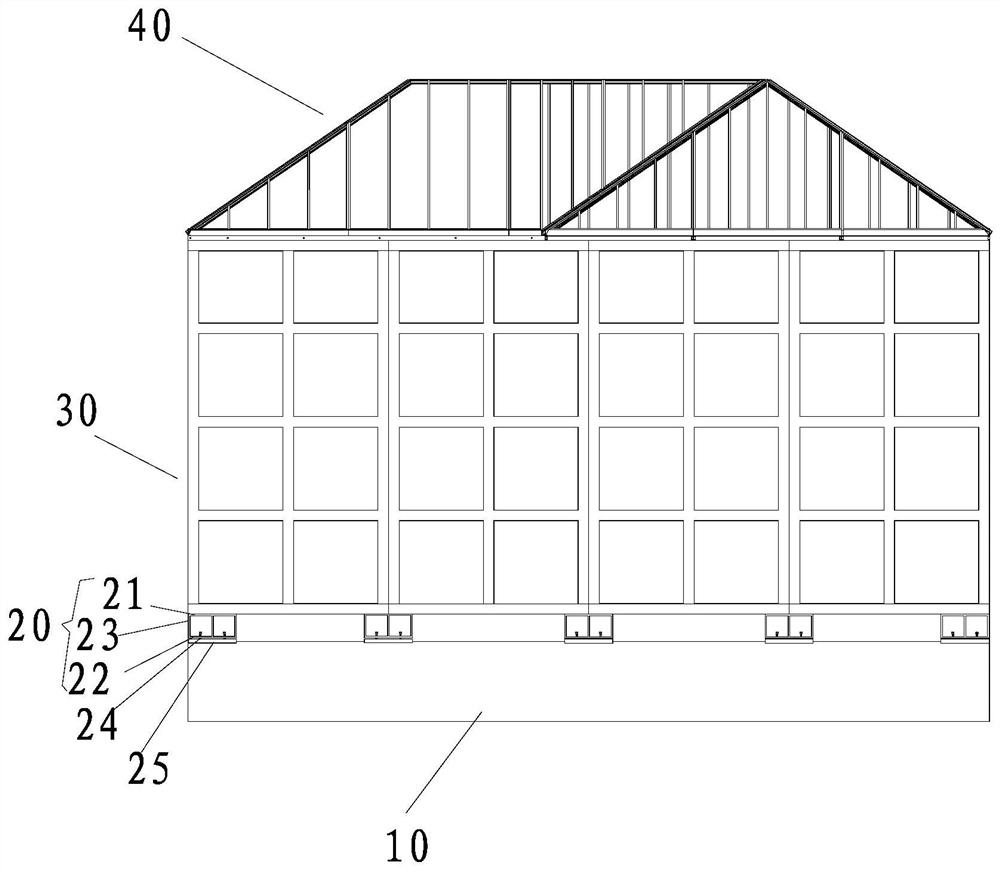

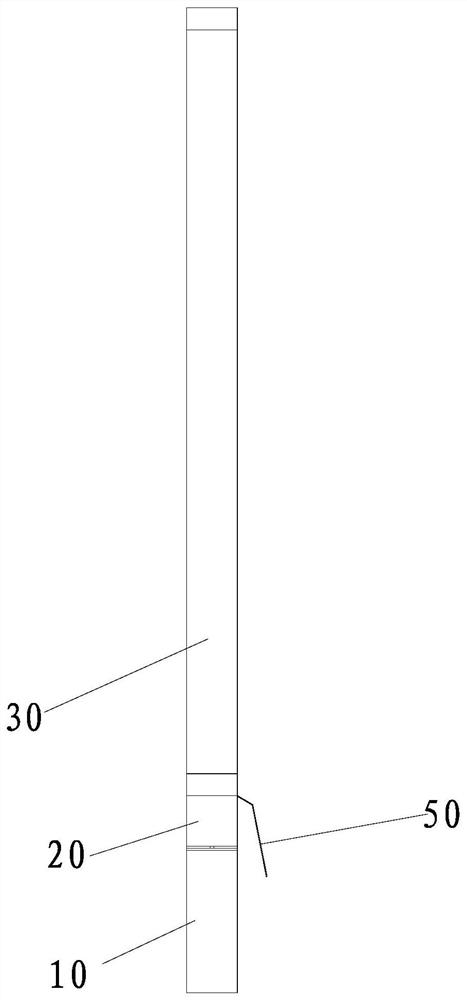

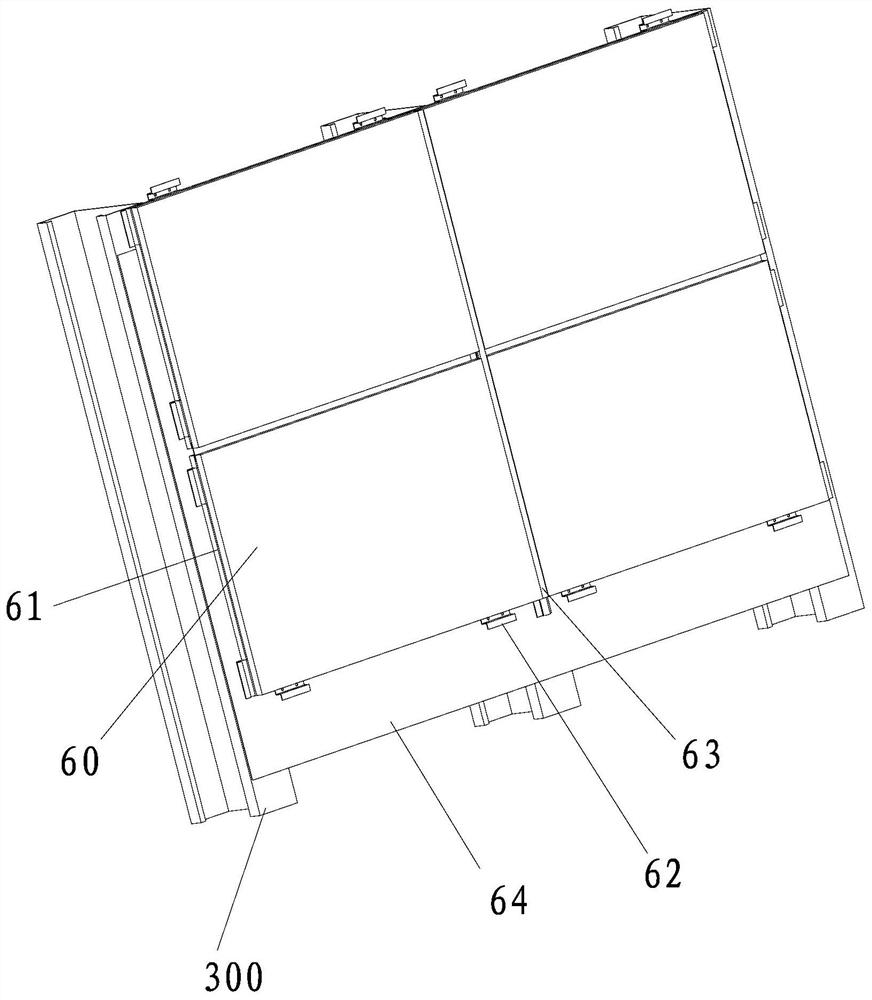

[0058] refer to Figure 1 to Figure 17 , a house structure comprising a foundation 10, a house body 30 formed on the foundation 10, and a roof 40 mounted on the house body 30, the house body 30 comprising a plurality of prefabricated integral body frames 300 and mounted on the main body The plate 60 on the frame 300, a plurality of main frames 300 are connected to the foundation 10 and enclose the accommodation space, the main frame 300 is a frame structure surrounded by a plurality of beams 301 and longitudinal beams 302. In the embodiment, the beams 301 and the longitudinal beams 302 form a rectangular frame, and longitudinal and lateral reinforcing beams are arranged in the rectangular frame to enhance the strength of the entire main frame 300 . The house body 300 of the present invention is surrounded by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com