Defective needle flaw detection method of circular knitting machine

A defect detection and large circular knitting technology, applied in the field of visual inspection, can solve problems such as weft shrinkage and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

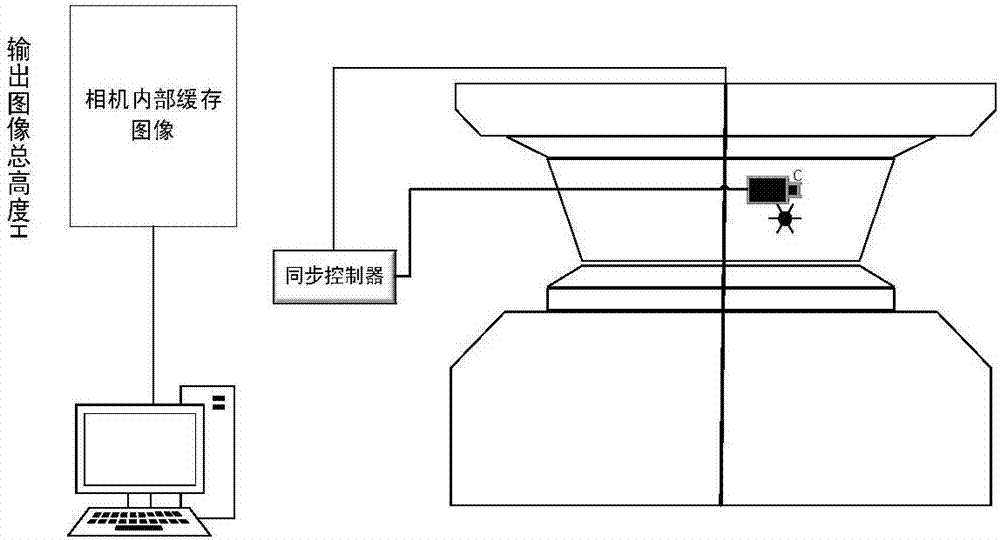

[0065] like figure 1 As shown, a method for detecting defective needles of a large circular knitting machine in the present invention is realized on the following hardware carriers: high-quality image acquisition equipment, a control terminal and a large circular knitting machine. The camera and light source are integrated into an image acquisition device and mounted inside the circular knitting machine. The camera captures fabric images and feeds them back to the control terminal for fabric defect detection.

[0066] Due to the high resolution of the sensor of the line scan camera itself and the pre-calibration of the light source to achieve accurate high-resolution image acquisition, the line scan camera can be selected.

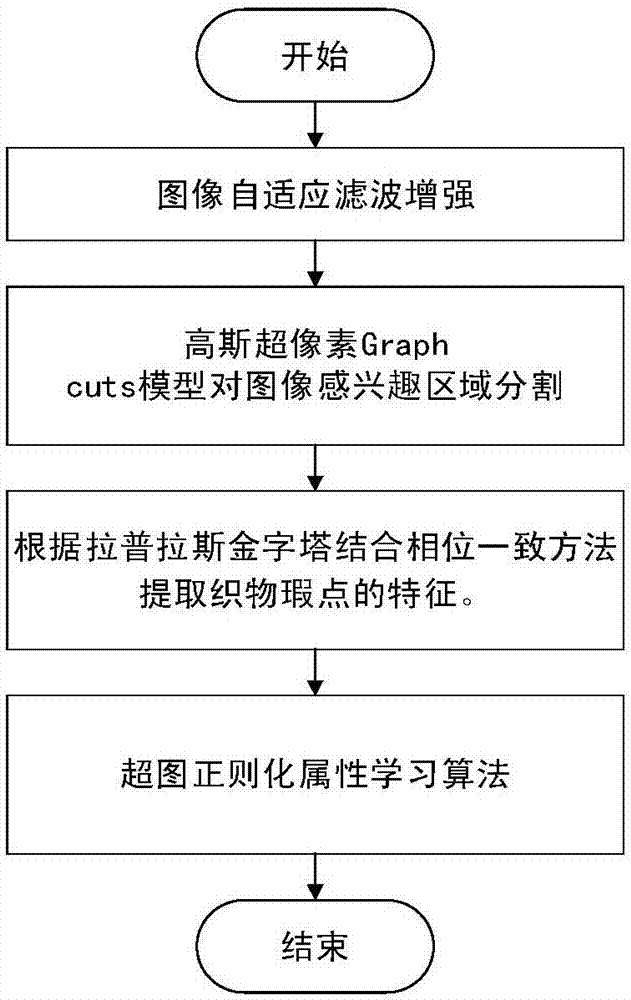

[0067] like figure 2 Shown, a kind of bad needle flaw detection method of large circular knitting machine of the present invention specifically comprises the following steps:

[0068] Step 1, collect the fabric image in real time through the image acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com